Nano ATO/Tio2 transparent thermal insulation coating for ultralow-VOC waterborne polyurethane/acrylic acid transparent building glass

A technology of water-based polyurethane and thermal insulation coatings, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of lack of systematic experimental research, high production costs, and insufficient water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

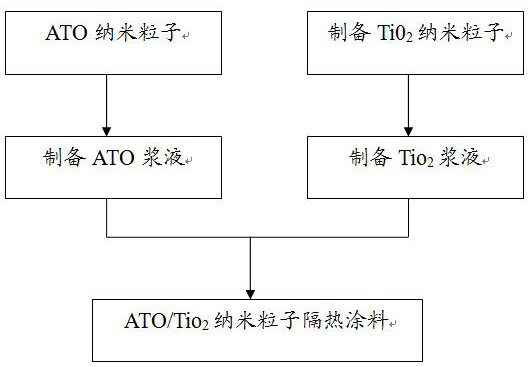

Method used

Image

Examples

Embodiment 1

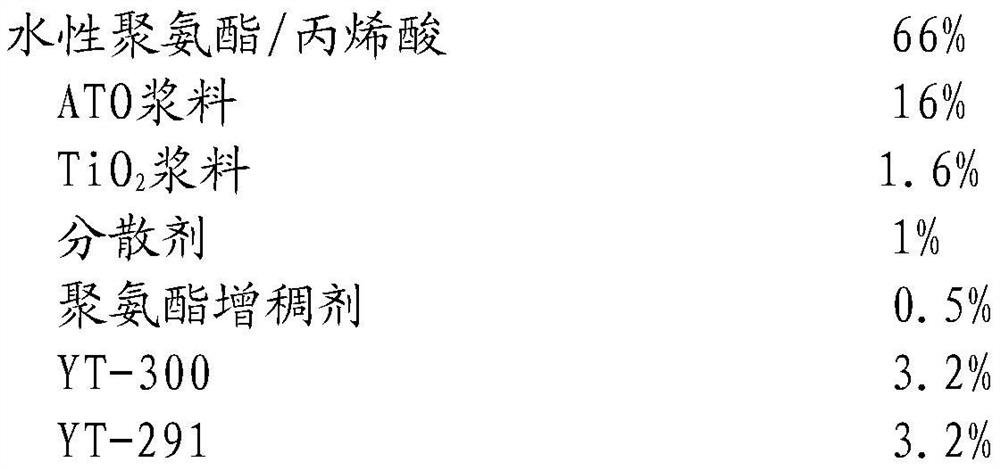

[0016] Embodiment 1: A kind of ultra-low VOC water-based polyurethane / acrylic acid nano-ATO / Tio used in architectural glass of this practical example 2 Transparent heat-insulating paint is made according to the general paint-making process. The specific ingredients of the formula and the ratio by quality are as follows:

[0017]

[0018]

[0019] According to the recipe, under magnetic stirring, ATO and TiO 2 Add the nano-slurry to the polyurethane solution, and add wetting agent, dispersant, thickener, film-forming aid, and leveling agent in sequence, mix at 1500r / min for 15min, disperse at 3000r / min for 25min, and then ultrasonically disperse for 20min , adjust the pH value to 7-9 with ammonia water; add deionized water to adjust the viscosity.

Embodiment 2

[0020] Embodiment 2: A kind of ultra-low VOC water-based polyurethane / acrylic acid nanometer ATO / Tio that this practical example is used for architectural glass 2 Transparent heat-insulating paint is made according to the general paint-making process. The specific ingredients of the formula and the ratio by quality are as follows:

[0021]

[0022] According to the recipe, under magnetic stirring, ATO and TiO 2Add the nano-slurry to the polyurethane solution, and add wetting agent, dispersant, thickener, film-forming aid, and leveling agent in sequence, mix at 1500r / min for 15min, disperse at 3000r / min for 25min, and then ultrasonically disperse for 20min , adjust the pH value to 7-9 with ammonia water; add deionized water to adjust the viscosity.

Embodiment 3

[0023] Embodiment 3: a kind of ultra-low VOC water-based polyurethane / acrylic acid nanometer ATO / Tio used in architectural glass of this actual example 2 Transparent heat-insulating paint is made according to the general paint-making process. The specific ingredients of the formula and the ratio by quality are as follows:

[0024]

[0025]

[0026] According to the recipe, under magnetic stirring, ATO and TiO 2 Add the nano-slurry to the polyurethane solution, and add wetting agent, dispersant, thickener, film-forming aid, and leveling agent in sequence, mix at 1500r / min for 15min, disperse at 3000r / min for 25min, and then ultrasonically disperse for 20min , adjust the pH value to 7-9 with ammonia water; add deionized water to adjust the viscosity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com