Detergent for machine-washed tableware and preparation method thereof

A detergent and tableware technology, applied in the field of daily chemical cleaning, can solve problems such as water eutrophication pollution, achieve strong cleaning and decontamination capabilities, simple operation steps, and reduce re-scaling and precipitation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

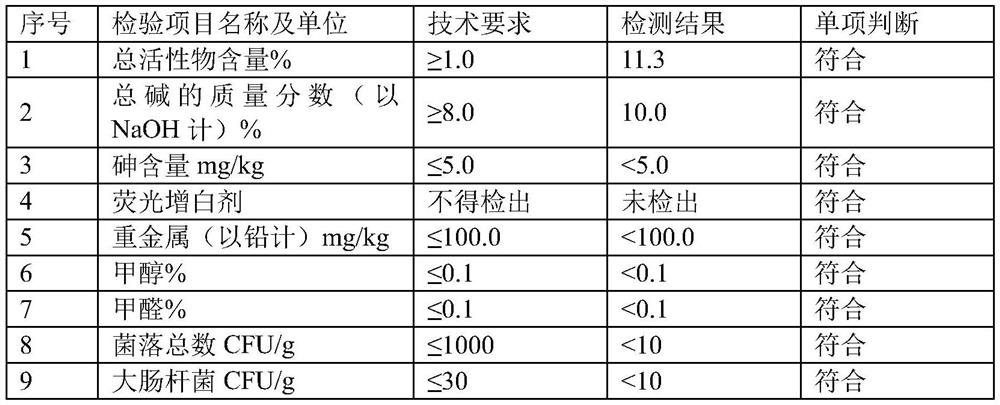

Embodiment 1

[0047] Embodiment 1: a kind of detergent for machine-washing tableware, 1000g is taken as an example to illustrate, and above-mentioned detergent is made of following raw material: strong lye 192g (19.2%);

[0048] Anionic dispersant 3g (0.3%);

[0049] Sodium citrate 23g (2.3%);

[0050] Water 783g (78.3%).

[0051] Wherein, strong lye is 50wt% sodium hydroxide solution; water is deionized water.

[0052] The anionic dispersant is Sokalan PA25 CL; the product brand of Sokalan PA25 CL is BASF, and the manufacturer is Kain Chemical.

[0053] The chemical name of sodium citrate (food grade) is trisodium citrate, the active substance content is 99.0-101.0%, the brand of sodium citrate (food grade) is Tianyang, and the manufacturer is Lianyungang Zhengrong Food Additive Factory.

[0054] The preparation method of the detergent for machine-washing tableware of above-mentioned embodiment 1, comprises the following steps:

[0055] Step 1. At room temperature and normal pressure, ...

Embodiment 2

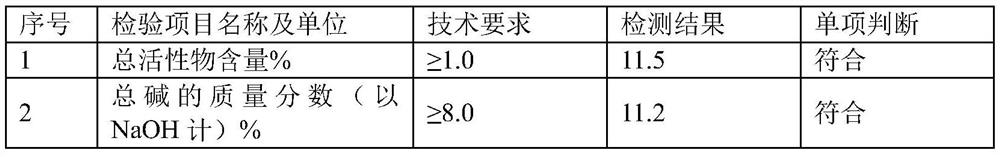

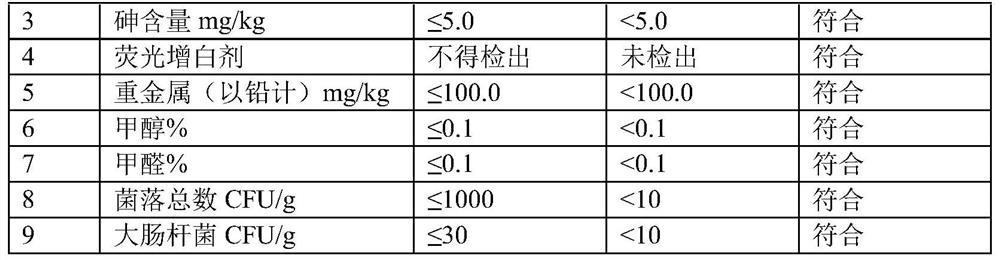

[0058] Embodiment 2: A kind of detergent for machine-washing tableware is illustrated by taking 1000g as an example. The above-mentioned detergent is made of the following raw materials:

[0059] Strong lye 150g (15%);

[0060] Anionic dispersant 10g (0.1%);

[0061] Sodium citrate (150g (1.5%);

[0062] Water 834g (83.4%).

[0063] Among them, the strong alkali solution is 40wt% sodium hydroxide solution; the anionic dispersant is Sokalan PA25 CL-FR; the manufacturer of Sokalan PA25 CL-FR is Guangzhou Shisheng Chemical Co., Ltd., the brand is 6598.

[0064] The preparation method of the detergent for machine-washing tableware of above-mentioned embodiment 2, comprises the following steps:

[0065] Step 1. At room temperature and normal pressure, add deionized water into the stirring vessel, start stirring, then add 40 wt% sodium hydroxide solution while stirring, and stir for 6 minutes at a stirring speed of 15 r / s.

[0066] Step 2: Add Sokalan PA25 CL-FR, and stir for 6 ...

Embodiment 3

[0068] Embodiment 3: A kind of detergent for machine-washing tableware is illustrated by taking 1000g as an example. The above-mentioned detergent is made of the following raw materials:

[0069] Strong lye 250g (25%);

[0070] Anionic dispersant 4g (0.4%);

[0071] Sodium citrate 30g (3%);

[0072] Water 716g (71.6%).

[0073] Wherein, strong lye is 50wt% potassium hydroxide solution. The anionic dispersant is sodium polyacrylate 445n, the brand of sodium polyacrylate 445n is Dow, the CAS number is 9003-04-7, the place of origin / manufacturer is Rohm and Haas, and the delivery address is Linyi City, Shandong Province.

[0074] The preparation method of the detergent for machine-washing tableware of above-mentioned embodiment 3, comprises the following steps:

[0075] Step 1. At room temperature and normal pressure, add deionized water into the stirring vessel, start stirring, then add 50 wt% potassium hydroxide solution while stirring, and stir for 10 minutes at a stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com