Compressed air jet type self-starting vertical axis wind turbine and detection method thereof

A wind turbine, self-starting technology, applied in the direction of the wind engine, wind engine, wind motor combination, etc. at right angles to the wind direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

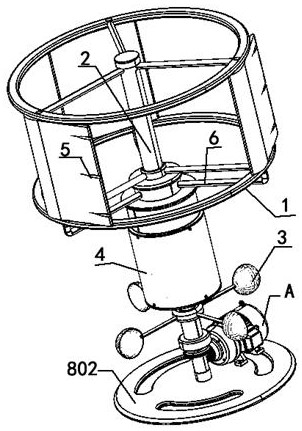

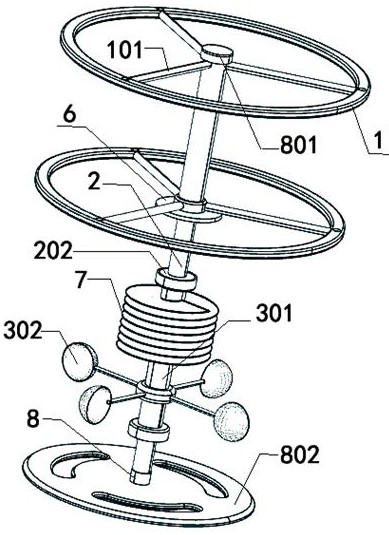

[0044] refer to Figure 1 to Figure 10 As shown, one embodiment of the present invention is a self-starting vertical axis wind turbine of a compressed air jet type, comprising a first impeller 1, and the above-mentioned first impeller 1 is installed on a power shaft 2, and is used for connecting the power shaft 2 and the power generating device The power connection, wherein the power generating device can be a generator A, the first impeller 1 is an existing lift-type impeller mechanism, the rotation of the first impeller 1 drives the power shaft 2 to rotate, and the power shaft 2 drives the generator A to work, and the power is generated by the power shaft 2. Machine A generates electricity.

[0045] A second impeller 3 is correspondingly provided on one side of the first impeller 1, that is, a second impeller 3 is arranged below or above the first impeller 1 to assist the rotation of the first impeller 1, wherein the second impeller 3 is an existing resistance type impeller ...

Embodiment 2

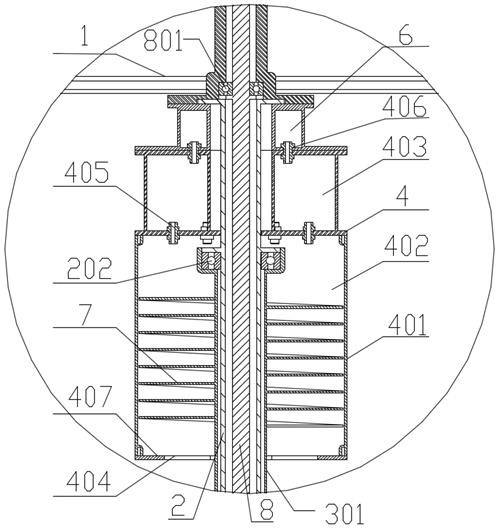

[0051] Based on the above embodiment and another embodiment of the present invention, the above-mentioned pressurized tank 4 includes a tank body 401, and the above-mentioned tank body 401 is provided with a pressurized chamber 402 and a high-pressure chamber 403, wherein the pressurized chamber 402 has the function of air pressurization , the high pressure chamber 403 plays the role of buffering the airflow. The lower end of the pressurizing chamber 402 is provided with an air inlet 404 with a downward opening, and the air inlet 404 of the pressurizing chamber 402 is placed downward and opens downward, thereby effectively preventing dust accumulation in the pressurizing chamber 402 .

[0052] It should be noted that, under the premise of ensuring that the air intake volume of the air inlet 404 meets the requirements, for the use environment of the wind turbine, the air inlet 404 can be installed with an anti-foreign matter cover 407 with air flow holes to prevent foreign matte...

Embodiment 3

[0058] Based on the above embodiments, refer to Figure 3 to Figure 5 As shown in another embodiment of the present invention, the above-mentioned power shaft 2 is hollow, the above-mentioned power shaft 2 is provided with a tower rod 8, the above-mentioned tower rod 8 is provided with a first bearing 801, and the movable end of the above-mentioned first bearing 801 is connected to the power shaft 2 The inner wall, that is, the tower rod 8 is a support rod, and the power shaft 2 is installed on the outside of the tower rod 8 through the first bearing 801 , so that the power shaft 2 can rotate when the tower rod 8 is stationary.

[0059] The lower end of the power shaft 2 is provided with a bevel gear 201 , which is used for power connection with the generator A by the bevel gear 201 . The bevel gear 201 is driven by the power shaft 2 to rotate, and the input shaft of the generator A is provided with an input gear that meshes with the bevel gear 201. The input gear rotates to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com