Electric power inspection intelligent defect detection method based on deep learning

A power inspection and defect detection technology, which is applied in image data processing, instruments, calculations, etc., can solve the problems of high labor intensity, inability to guarantee the personal safety of workers, and low work efficiency, and achieve short processing time, high precision, Robust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

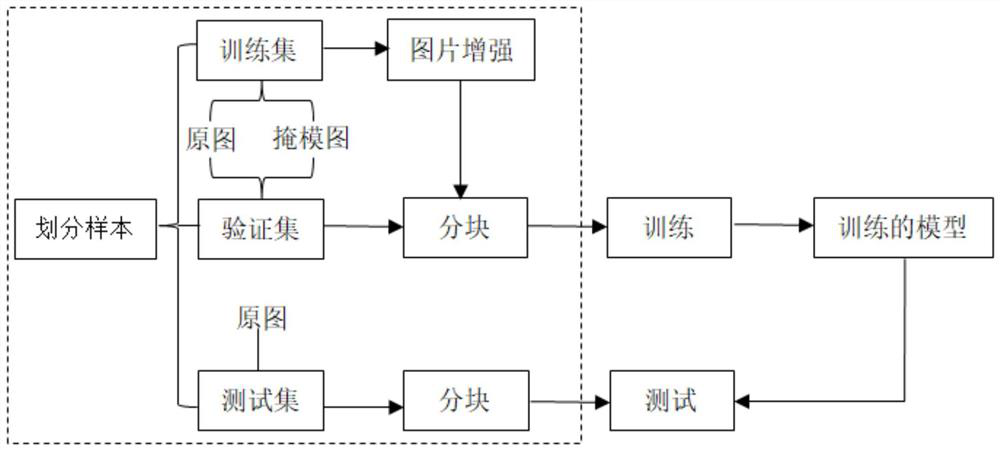

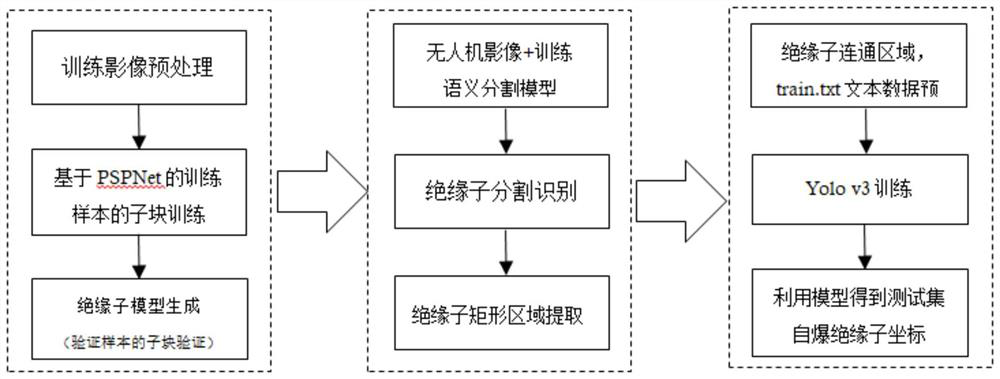

[0061] refer to Figure 1-26 , an intelligent defect detection method for power inspection based on deep learning, including:

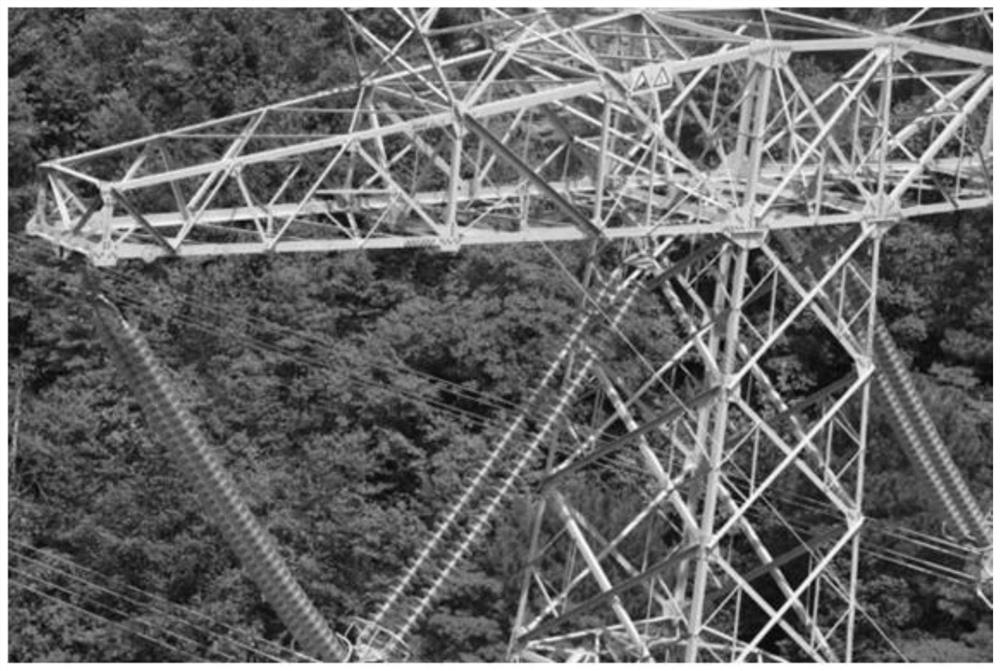

[0062] Obtain a plurality of original images of different insulators, the original images can be obtained by aerial photography of drones or helicopters, in this embodiment, obtain 40 original images of high resolution of different insulators;

[0063] A plurality of original images are divided into a training set and a test set, that is, 40 original images are divided into a training set and a test set, which is an average division in this embodiment;

[0064] Enhance the original image of the training set to obtain multiple times the number of enhanced set images;

[0065] Perform block processing on each enhanced set image and the original image in the test set to obtain multiple sub-block images and their mask...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com