Iron-cobalt organic catalyst, preparation method thereof and application of iron-cobalt organic catalyst in synthesis of benzoazacycle by CO2 conversion

An organic catalyst and catalyst technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, organic chemistry, etc., can solve the problems of reactor requirements, tedious preparation of photosensitizers, etc., and achieve preparation Simple method, high reproducibility, large surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A preparation method for an iron-cobalt organic catalyst, comprising the steps of: adding 0.1mmol terephthalic acid to a mixed solvent of DMF and dehydrated alcohol in a volume ratio of 1:0.1 in 50mL and stirring to dissolve, then adding 1mmol FeCl 3 Stir for 10 minutes, then add 10mmol Co(NO 3 ) 2 ·6H 2 O stirred for 10 minutes, and reacted at 200°C for 15 hours. After the product was alternately washed with absolute ethanol and DMF for 4 times, the quality would no longer decrease. drying in an oven, and drying at 100° C. for 5 hours to obtain an iron-cobalt organic catalyst.

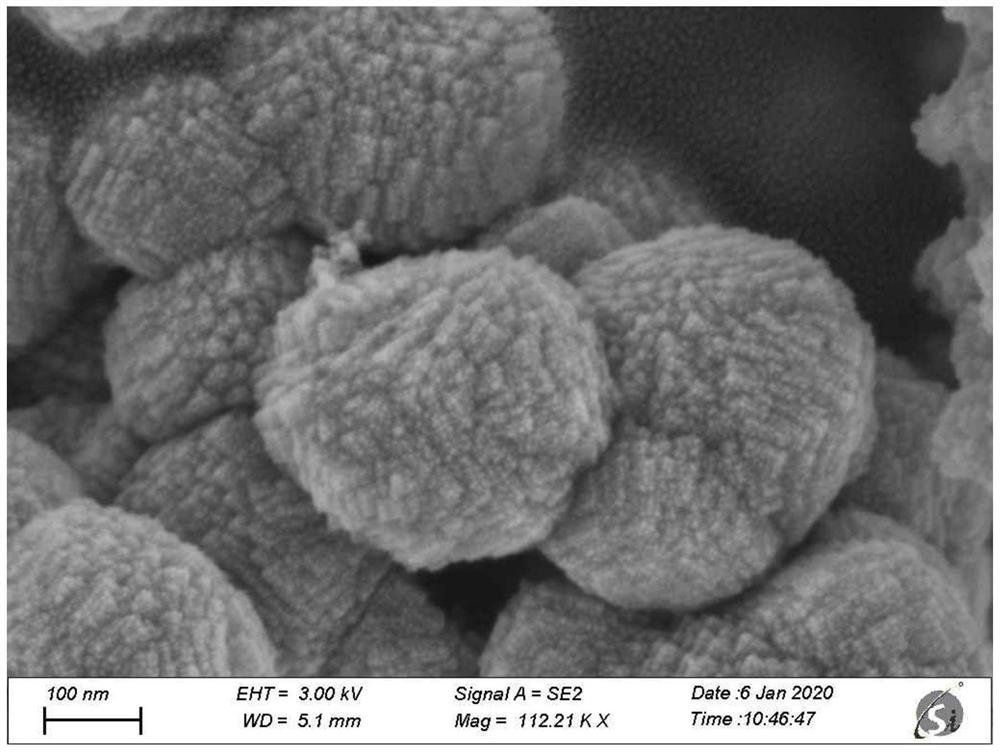

[0017] The SEM figure of described iron-cobalt organocatalyst is as figure 1 As shown, the catalyst is a microsphere with a diameter of 200-400nm, and there are layered crystals on the surface of the microsphere.

[0018] Applying the iron-cobalt organocatalyst to the conversion of CO 2 Synthesis of benzoazepine heterocycles: Add 1 mg of the iron-cobalt organic catalyst to 5 mL of 0.05 mmo...

Embodiment 2

[0020] A preparation method for an iron-cobalt organic catalyst, comprising the steps of: adding 0.5 mmol of 1,4,5,8-naphthalene tetracarboxylic acid and stirring and dissolving in a mixed solvent of DMF and absolute ethanol at a volume ratio of 1:10 in 50 mL, Then add 5mmol FeCl 3 Stir for 15 minutes, then add 5mmolCo(NO 3 ) 2 ·6H 2 O stirred for 5 minutes, reacted at 150°C for 10 hours, the product was alternately washed with absolute ethanol and DMF for 5 times, and the quality no longer decreased. The amount of each washing liquid was 10ml of mixed solution per mole of product, and the product was put into vacuum drying drying in an oven, and drying at 80° C. for 10 hours to obtain an iron-cobalt organic catalyst.

[0021] The iron-cobalt organic catalyst is a microsphere with a diameter of 300-400nm, and layered crystals are formed on the surface of the microsphere.

[0022] Applying the iron-cobalt organocatalyst to the conversion of CO 2 Synthesis of benzazepine ri...

Embodiment 3

[0024] A preparation method for an iron-cobalt organic catalyst, comprising the steps of: adding 1 mmol of 2,5-pyridinedicarboxylic acid to a mixed solvent of 1:5 DMF and absolute ethanol in a volume ratio of 50 mL, stirring and dissolving, then adding 10 mmol FeCl 3 Stir for 5 minutes, then add 1 mmol Co(NO 3 ) 2 ·6H 2 O stirred for 5 minutes, and reacted at 180°C for 20 hours. After the product was alternately washed with absolute ethanol and DMF for 4 times, the mass no longer decreased. The amount of each washing solution was 5ml of mixed solution per mole of product, and the product was put into vacuum drying. drying in an oven, and dried at 90° C. for 8 hours to obtain an iron-cobalt organic catalyst.

[0025] The iron-cobalt organic catalyst is a microsphere with a diameter of 200-400nm, and layered crystals are formed on the surface of the microsphere.

[0026] Applying the iron-cobalt organocatalyst to the conversion of CO 2Synthesis of benzoazepine heterocycles: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com