Multi-station steel ingot demolding system and method

A multi-station, steel ingot technology, applied in the field of metallurgical casting molds, can solve the problems of low demoulding efficiency and poor effect of steel ingots, and achieve the effect of good demoulding effect, simple system structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

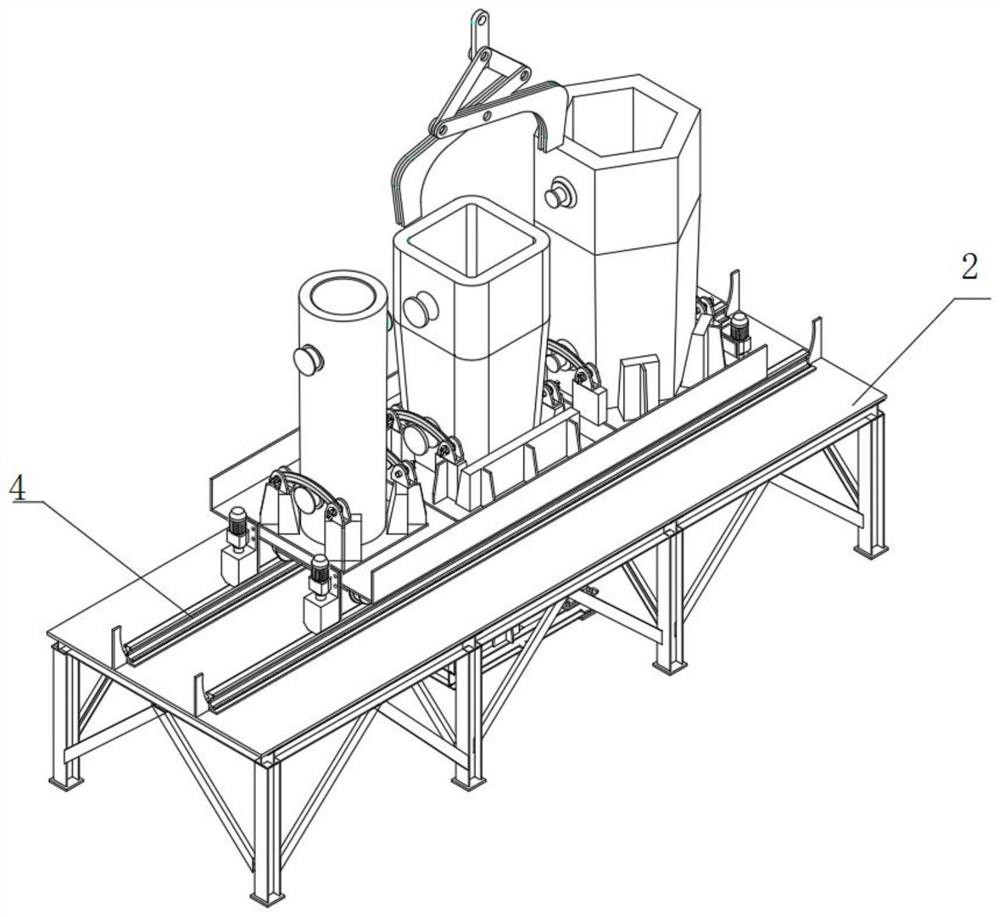

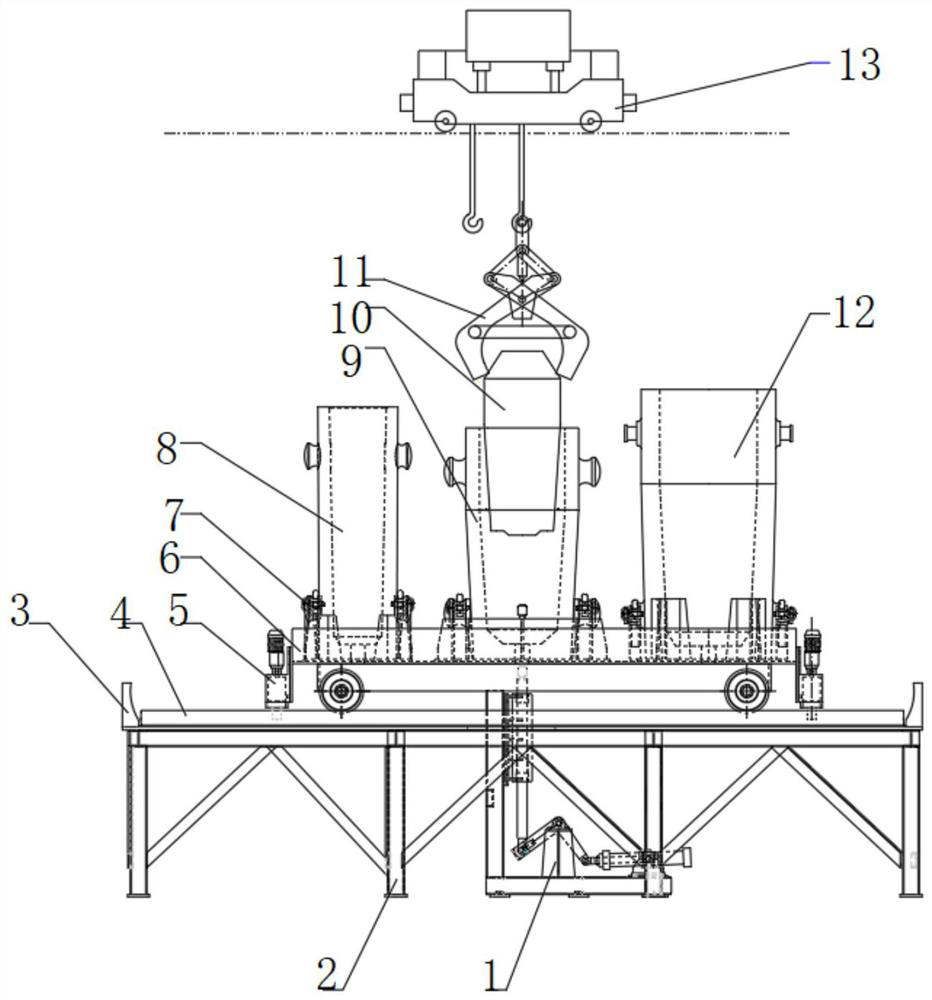

[0049] Such as figure 1 and figure 2 As shown, a multi-station steel ingot demoulding system includes a fixed seat 2, which is fixed on the ground and plays a supporting role for the entire system. A working platform is arranged above the fixed seat 2, and a hoisting device is arranged above the working platform. In this implementation, the hoisting device is a crane 13, and a main hook and an auxiliary hook are arranged on the crane 13. The main hook is used for lifting For mold transportation, since the upper and lower parts of each mold are provided with lifting lugs, the main hook hooks the lifting lugs on the upper part of the mold through a chain to lift the mold vertically; Tool 11, the demoulding spreader 11 is a gravity spreader, realizes the clamping and lifting of the steel ingot 10 under the action of gravity, different hooks realize the lifting of different objects, the division of labor is clear and does not affect each other; at the same time, the driving 13 c...

Embodiment 2

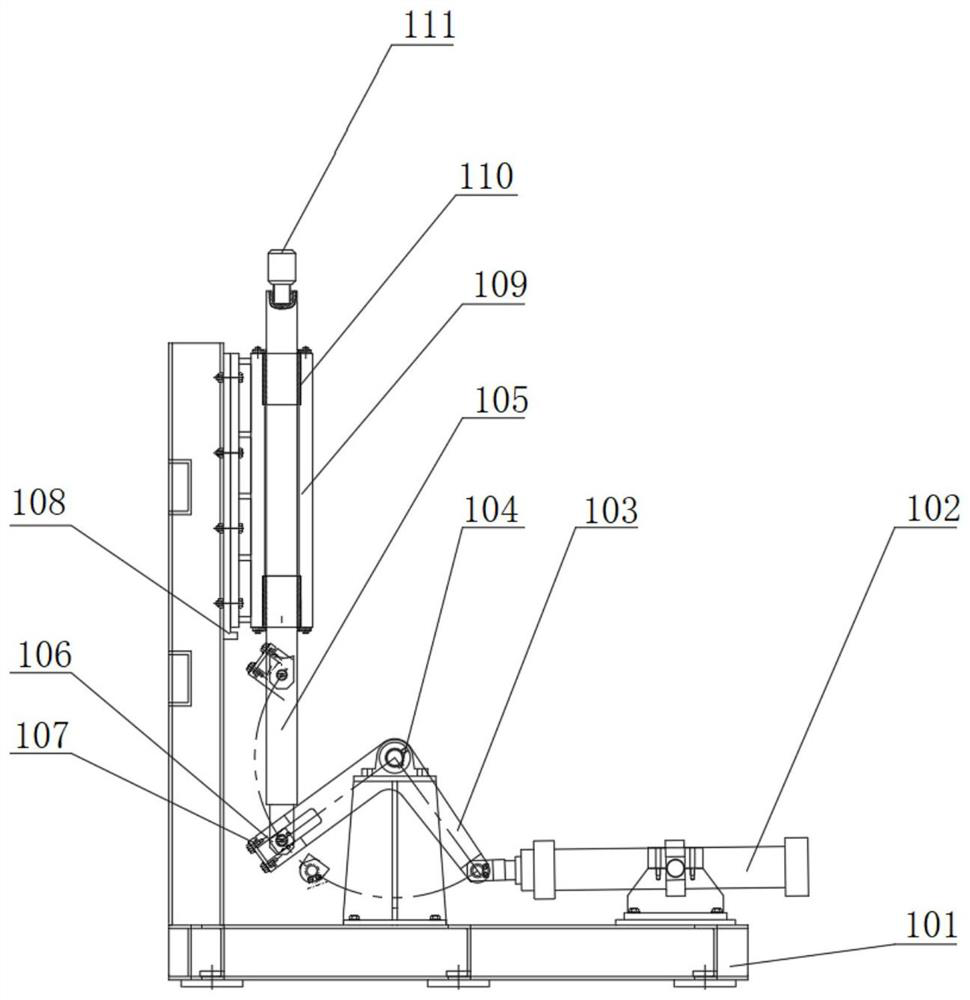

[0058] Basically the same as embodiment 1, in this implementation, the outer side of the said push rod 105 is provided with a guide seat 109, that is, the push rod 105 expands and contracts in the guide seat 109, and the setting of the guide seat 109 plays a role for the push rod 105 on the one hand. The protective function prevents the ejector rod 105 from being worn out by the external environment, and improves the service life of the ejector rod 105; on the other hand, it plays a guiding role in the up and down movement of the ejector rod 105, preventing the ejector rod 105 from tilting when it moves up and down. The guide seat 109 is connected with the mounting plate 108 arranged on the mounting seat 101. Specifically, the mounting seat 101 is arranged horizontally, and the mounting plate 108 is arranged at one end of the mounting seat 101 and is vertical to the mounting seat 101. On the mounting plate 108 There are several extension plates arranged in parallel, the extensi...

Embodiment 3

[0061] Basically the same as Embodiment 2, the difference from Embodiment 2 is that the working platform in this embodiment is movable. Such as Figure 5 As shown, the working platform includes a track 4 arranged on the fixed seat 2, an electric flat car 6 arranged on the track 4, and several demoulding stations are arranged on the electric flat car 6, and the electric flat car 6 and the motor 62 Connected, the electric flat car 6 can move back and forth on the track 4. And in order to prevent the electric flat car 6 from delimiting the track 4 and causing a safety accident due to falling, the present embodiment is provided with a limit device 3 at both ends of the track 4. The limit device 3 is a steel plate, and the steel plate is vertically arranged on the track 4. The two ends of 4 play a position-limiting effect on the electric flat car 6 to ensure the safety performance of the electric flat car 6 moving. The bottom of each casting mold is provided with a fixing hole to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap