Production and printing process for pearl white aluminum-foil paper

A technology of aluminum foil paper and pearl white, used in printing, special paper, post-processing of printing, etc., can solve the problems of discoloration of aluminum foil paper, constant drying temperature, and skinning on the surface of the adhesive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

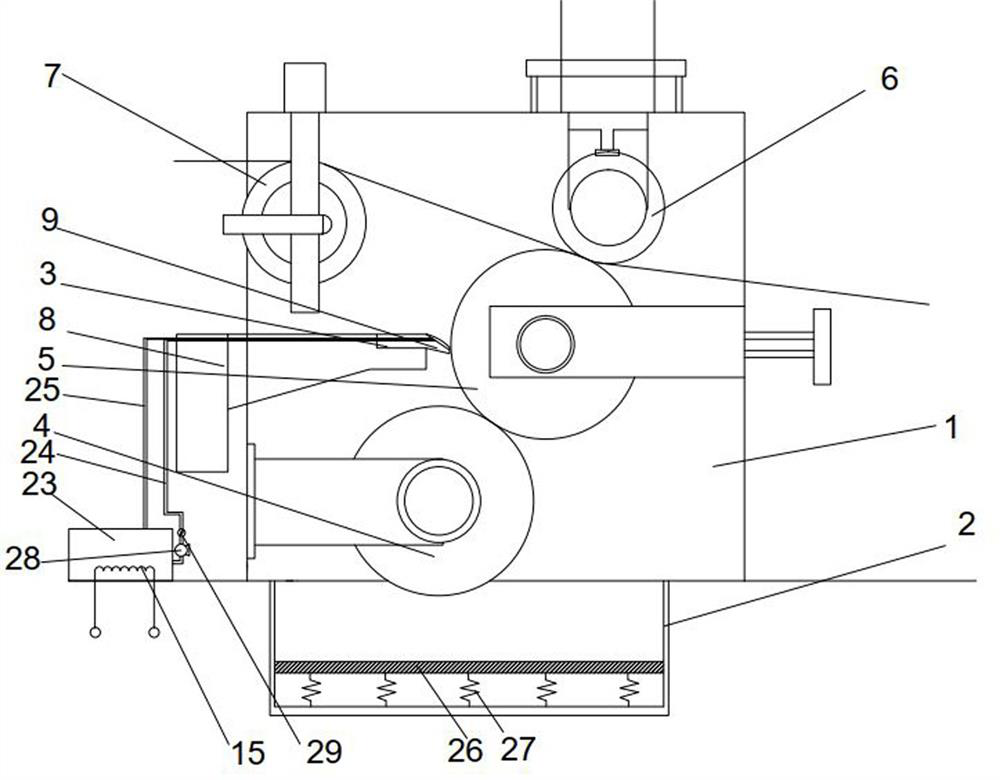

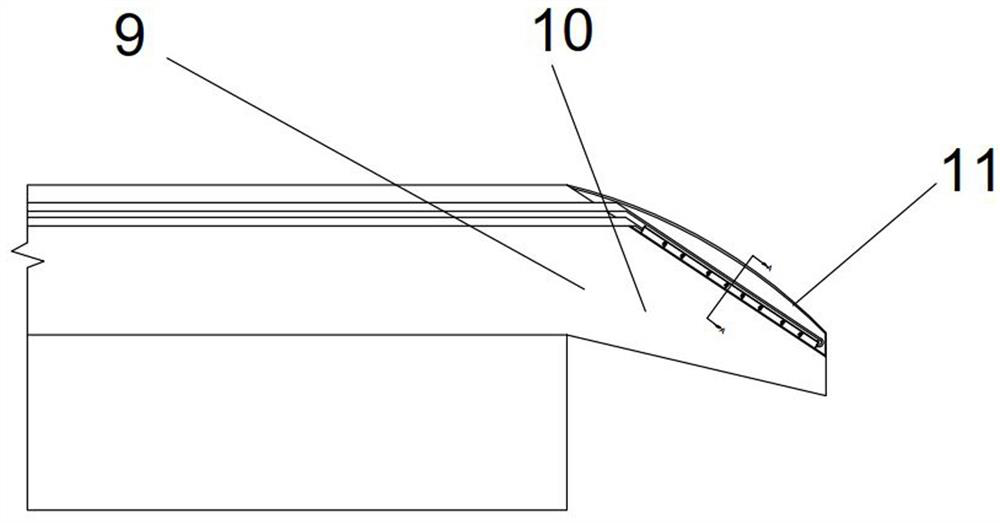

[0029] The technical scheme that the present invention takes is as follows:

[0030] 1) Attach hot melt adhesive to the PET film with aluminum foil;

[0031] 2) Laminate the bright copper paper on the aluminum foil;

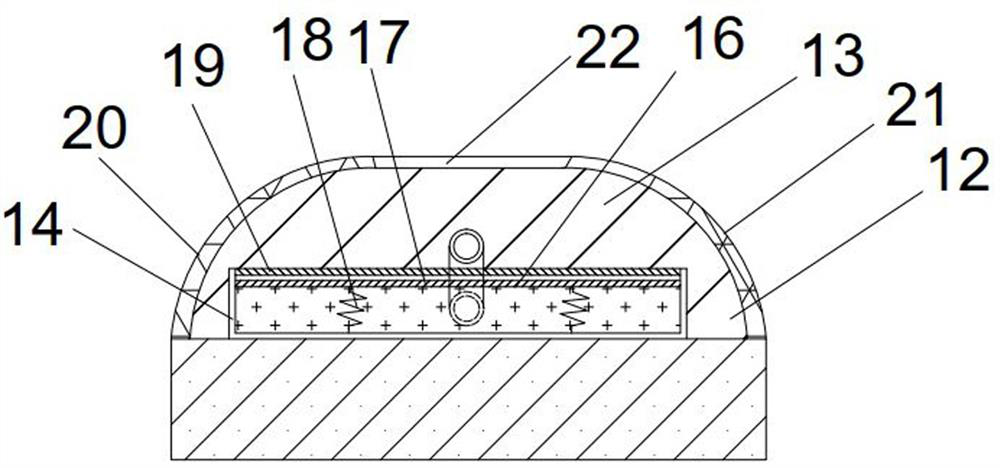

[0032] 3) Pressing with a high-temperature roller with a built-in heater to obtain aluminum foil paper;

[0033] 4) Roll up the laminated aluminum foil;

[0034] 5) Compound the golden layer on the aluminum surface of the aluminum foil paper through a wet compound machine. The composite ink uses DT-505 water-based paint and red-yellow paste. The diluent is a mixed solvent of alcohol and water. The glue used in the compound It is white latex; the composite process is dried in an oven, the oven includes five temperature control areas, the temperature in the first area is controlled at 70°C, the temperature in the second area is controlled at 90°C, and the temperature in the third area is controlled at At 120°C, the temperature in the fourth zone is controlled at...

Embodiment 2

[0037] The technical scheme that the present invention takes is as follows:

[0038] The technical scheme that the present invention takes is as follows:

[0039] 1) Attach hot melt adhesive to the PET film with aluminum foil;

[0040] 2) Laminate the bright copper paper on the aluminum foil;

[0041] 3) Pressing with a high-temperature roller with a built-in heater to obtain aluminum foil paper;

[0042] 4) Roll up the laminated aluminum foil;

[0043] 5) Compound the golden layer on the aluminum surface of the aluminum foil paper through a wet compound machine. The composite ink uses DT-505 water-based paint and red-yellow paste. The diluent is a mixed solvent of alcohol and water. The glue used in the compound It is white latex; the composite process is dried in an oven, and the oven includes five temperature control areas, the temperature of the first area is controlled at 50°C, the temperature of the second area is controlled at 70°C, and the temperature of the third are...

Embodiment 3

[0046] The technical scheme that the present invention takes is as follows:

[0047] 1) Attach hot melt adhesive to the PET film with aluminum foil;

[0048] 2) Laminate the bright copper paper on the aluminum foil;

[0049] 3) Pressing with a high-temperature roller with a built-in heater to obtain aluminum foil paper;

[0050] 4) Roll up the laminated aluminum foil;

[0051] 5) Compound the golden layer on the aluminum surface of the aluminum foil paper through a wet compound machine. The composite ink uses DT-505 water-based paint and red-yellow paste. The diluent is a mixed solvent of alcohol and water. The glue used in the compound It is white latex; the composite process is dried in an oven, and the oven includes five temperature control areas, the temperature of the first area is controlled at 60°C, the temperature of the second area is controlled at 80°C, and the temperature of the third area is controlled at At 110°C, the temperature in the fourth zone is controlle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| winding tension | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com