LNG ship heat energy comprehensive utilization system

A thermal energy and ship technology, applied in ship propulsion, material loading system, hull ventilation/heating/cooling, etc., can solve the problem that cold energy cannot be effectively used, and achieve comprehensive utilization, improve desalination efficiency, and improve taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

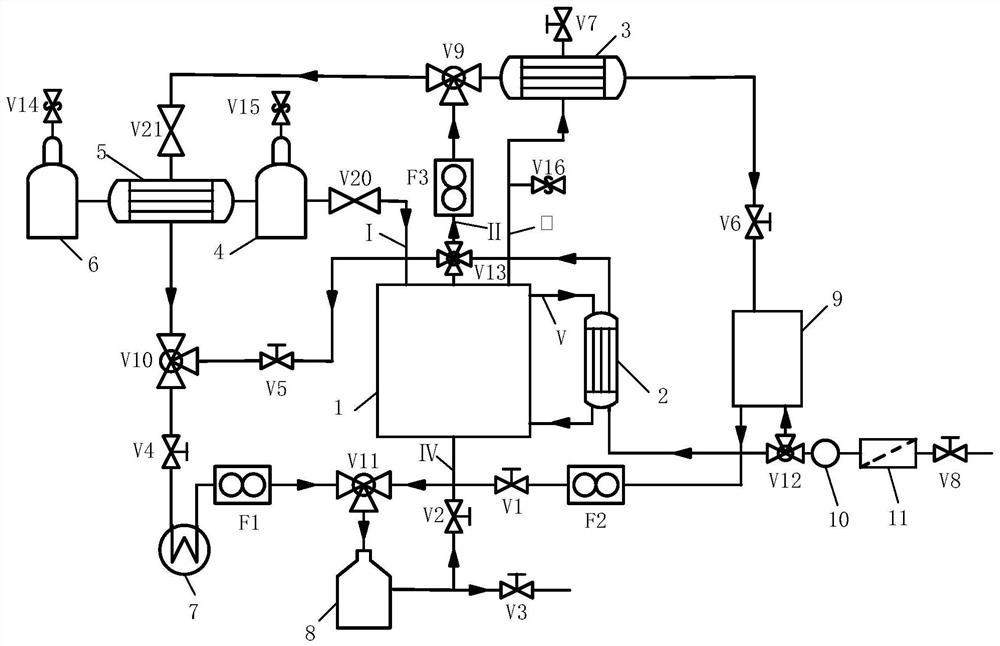

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0029] Such as figure 1 As shown, a comprehensive utilization system for LNG ship thermal energy provided by the present invention includes LNG engine 1, closed cycle heat exchanger 2, exhaust gas heat exchanger 3, tube bundle heat exchanger 5, CNG cylinder 4, LNG steam Bottle 6, radiator coil 7, low-temperature cooling water tank 8, evaporative desalination machine 9, seawater pump 10. Among them, the LNG engine 1 provides heat energy for the whole system, and the comprehensive utilization system of LNG ship heat energy mainly has four functional modules: 1) a self-constant-pressure self-transformation module composed of an LNG cylinder 6, a tube bundle heat exchanger, and a CNG cylinder 4, It is used to realize self-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com