Sample injection bottle grabbing cover opening and closing mechanism

A technology for opening and closing caps and sampling bottles, which is applied in screw caps, bottle/container caps, bottle filling, etc. It can solve the needs of large grip space occupation, large volume, and inability to adapt to the miniaturization of automation equipment, etc. Problems, to achieve the effect of small space occupation, cost reduction, and automation equipment size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation of the mechanism for grasping and opening and closing the sampling bottle of the present invention will be described in detail below in conjunction with the accompanying drawings.

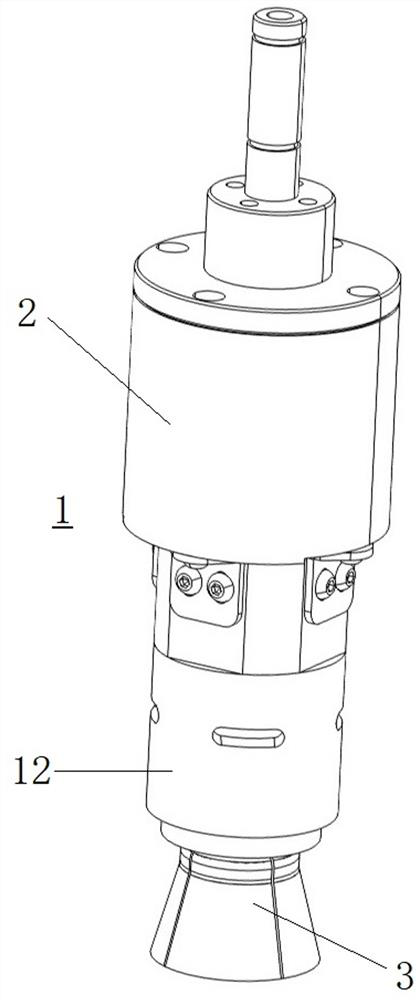

[0037] See attached figure 1 , The sampling bottle grasping opening and closing mechanism 1 is used to grab the cap of the sampling bottle and operate the sampling bottle. Below the cover opening and closing mechanism 1 is a gripper, and a telescopic drive mechanism 4 is arranged inside, and the gripper is driven by the telescopic drive mechanism 4 to grab the sample bottle.

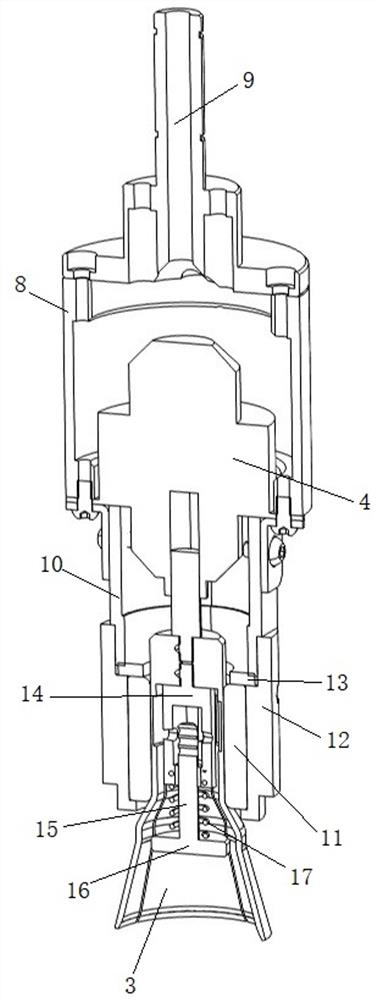

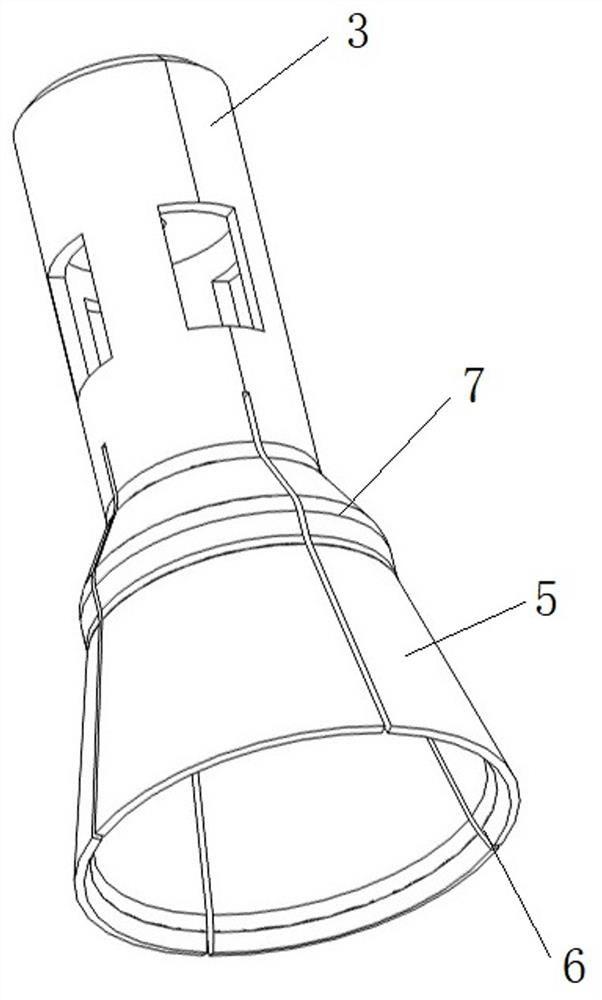

[0038] See attached figure 2 The inside of the cylindrical shell 2 of the opening and closing cover mechanism 1 is hollow, and the jaw body 3 is arranged at the lower part 11 of the shell 2. The shaft is fixed, and the telescopic drive mechanism 4 is a stepping motor, and the main shaft of the stepping motor and the head of the jaw body 3 are fixed by fasteners. Telescopic drive mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com