An integrated device for biochemical treatment enhanced by powder carrier

A powder carrier and biochemical treatment technology, which is applied in biological water/sewage treatment, reflux water treatment, water/sludge/sewage treatment, etc. It can solve the problems of unsatisfactory treatment effect, large floor area, and long sewage treatment time , to achieve the effect of overcoming low sludge concentration, high volume load, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

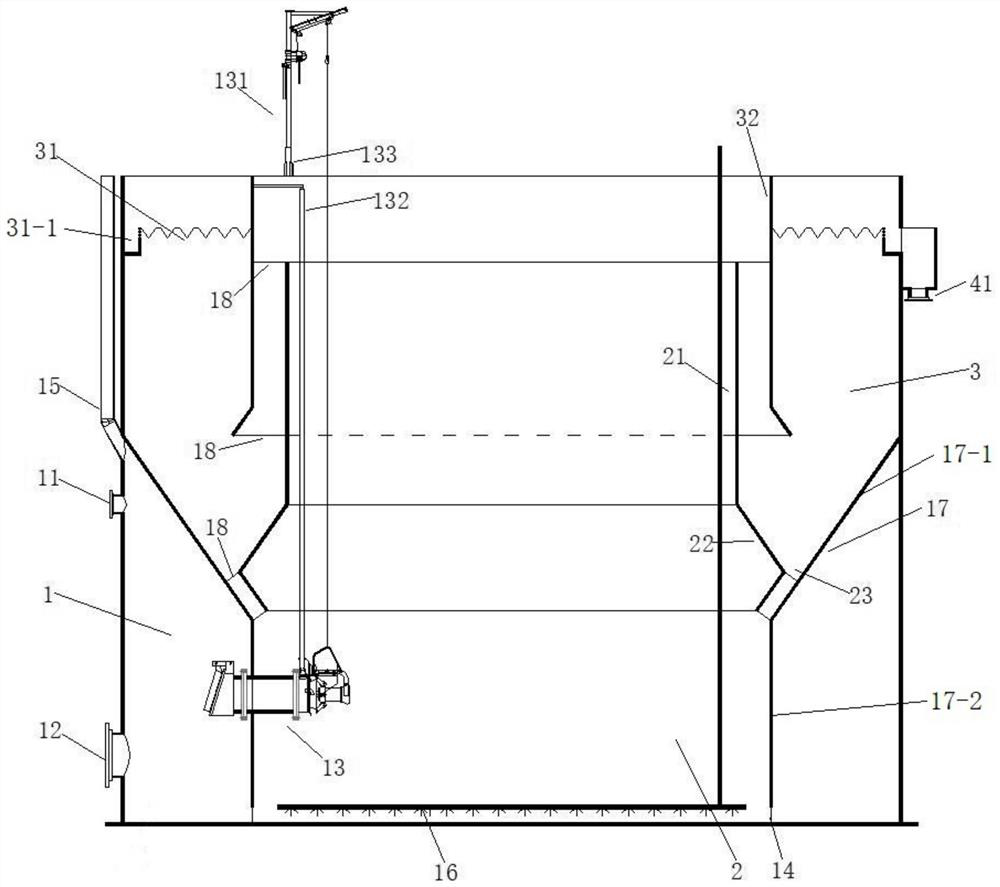

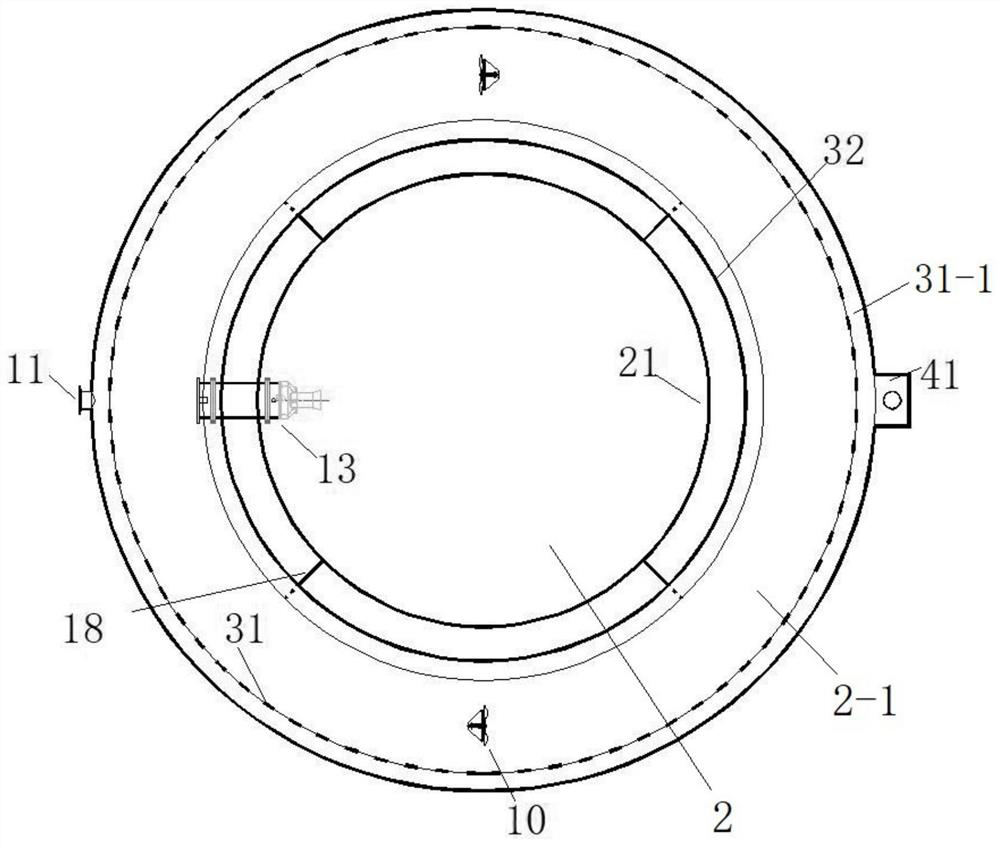

[0034] Such as Figure 1-2 As shown, it is a powder carrier-enhanced biochemical treatment integrated device provided in this embodiment. The device is cylindrical, including a central cylindrical aerobic zone 2, an anoxic / precipitation zone 2-1 surrounding the aerobic zone 2, The anoxic / precipitation zone 2-1 includes an anoxic zone 1 with a water inlet 11, a precipitation zone 3 located on the upper part of the anoxic zone 1, and the device also includes a bottom flow hole 14 connecting the anoxic zone 1 and the aerobic zone 2 , Return the sewage nitrifying liquid in the aerobic zone 2 to the submersible internal return pump 13 in the anoxic zone 1; the aerobic zone 2 and the anoxic / sedimentation zone 2-1 pass through the inner compartment 21 with a horn-shaped annular guide plate 22 , an outer compartment 32 with a trumpet-shaped annular guide plate 32-1 and a partition partition 17 with an inwardly inclined portion 17-1 and a vertical portion 17-2 to the central axis of th...

Embodiment 2

[0050] The difference between this embodiment and embodiment 1 is that the volume ratio of the anoxic zone 1 to the aerobic zone 2 is 1:2, and the surface load of the precipitation zone 3 is 0.6m 3 / m 2 h, the volume load of the device when denitrification / nitrification biological denitrification is 0.4Kg BOD 5 / m 3 d. The aeration system 16 adopts an aeration pan.

[0051] The power of the submersible plug flow mixer 10 is 0.6W / m 3 , the push flow velocity of the submerged push flow mixer 10 is 0.3m / s, and the flow velocity of the mixed sewage in the maintenance device through the bottom flow hole 14 is 0.4m / s; the distance between the overflow weir 31 and the top of the device shell is 300mm, the water outlet notch 41 is lower than the overflow weir 31, and the distance between the bottom of the sump 31-1 and the bottom of the overflow weir 31 is 200mm.

Embodiment 3

[0053] The difference between this example and Example 1 and Example 2 is that the volume ratio of the anoxic zone 1 to the aerobic zone 2 is 1:2.5, and the surface load of the precipitation zone 3 is 1.0m 3 / m 2 h, the volume load of the device when denitrification / nitrification biological denitrification is 1.0KgBOD 5 / m 3 d. The aeration system 16 adopts a tube aerator.

[0054] The power of submersible plug flow mixer 10 is 0.75W / m 3 , the push flow velocity of the submerged push flow mixer 10 is 0.35m / s, and the flow velocity of the mixed sewage in the maintenance device through the bottom flow hole 14 is 0.55m / s; the distance from the overflow weir 31 to the top of the device shell is 500mm, the water outlet notch 41 is lower than the overflow weir 31, and the distance between the bottom of the sump 31-1 and the bottom of the overflow weir 31 is 400mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com