A kind of two-dimensional polymer brush and its crystal and preparation method

A polymer brush and crystal technology, applied in the field of two-dimensional materials, can solve complex photolithography steps, damage and other problems, achieve high-efficiency connection, ensure completeness, and reduce the difficulty of characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] A method for preparing a two-dimensional polymer brush, comprising the following steps:

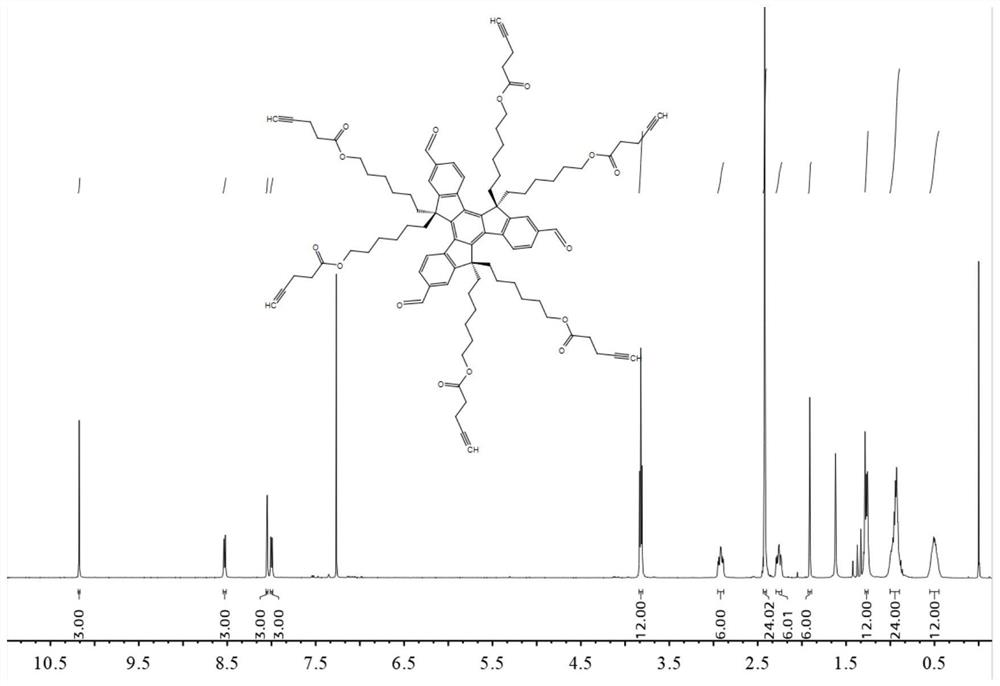

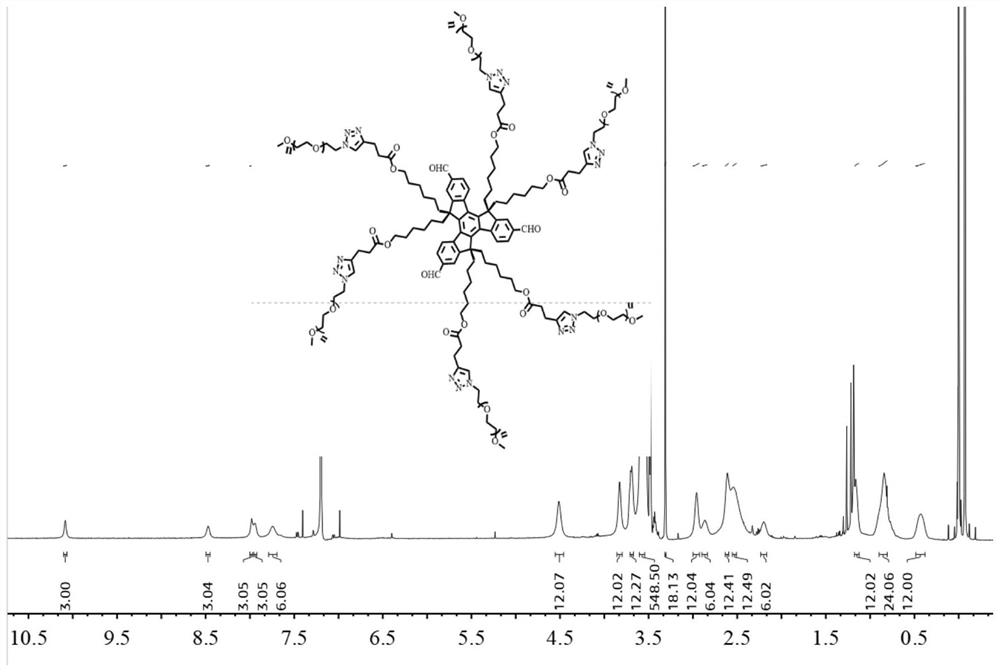

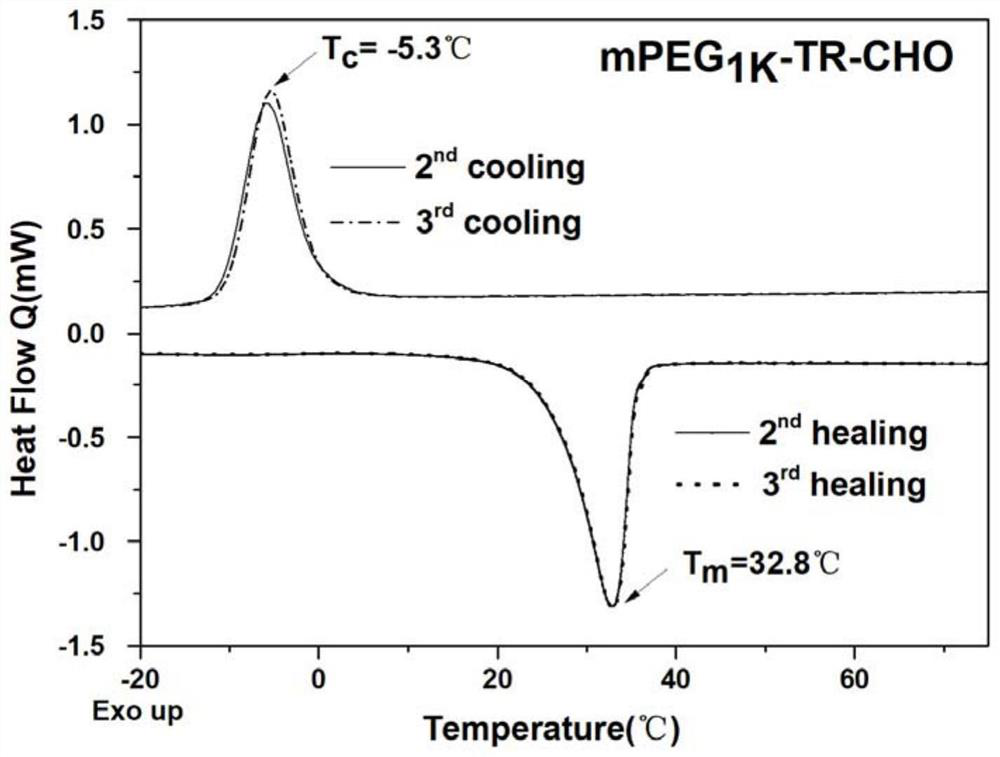

[0052](1) prepare the aldehyde-based monomer (being compound 4) of following structure, specifically comprise the following steps:

[0053]

[0054] Step (1): Synthesis of compound 1:

[0055]

[0056] Add tribromotridene (200mg, 0.345mmol) and potassium tert-butoxide (571.2mg, 5.1mmol) into the two-neck flask, after nitrogen protection, add 30mL of anhydrous THF, raise the temperature to 60°C, react for 30min, and gradually add 2-(6-Bromohexyl)tetrahydropyran (914.9mg, 3.45mol), stirred overnight; after the reaction was completed, quenched the reaction by adding water, extracted 3-4 times with dichloromethane, and the organic phase was extracted by anhydrous magnesium sulfate After drying and filtering, the solvent was distilled off under reduced pressure; the obtained crude product was purified by silica gel column chromatography and recrystallized to obtain a light yellow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com