Packaging adhesive tape for acrylic resin lens and preparation method of packaging adhesive tape

An acrylic resin, lens technology, applied in film/sheet adhesives, adhesives, amide/imide polymer adhesives, etc. Poor liquid matching, easy deformation and damage of lens packaging tape, etc., to achieve good flexibility and mechanical properties, improve residual glue and sealing problems, and ensure the quality of finished spectacle lenses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

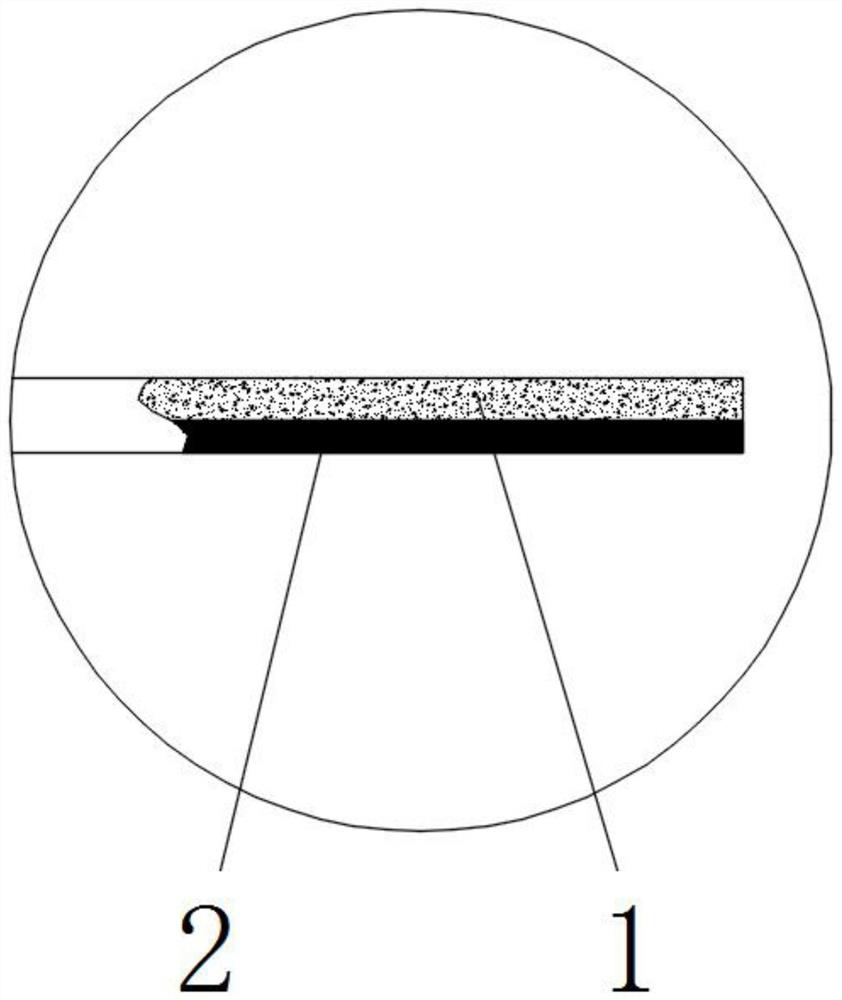

Image

Examples

preparation example Construction

[0037] A kind of preparation method of the encapsulation tape of acrylic resin lens, concrete operation steps are as follows:

[0038] 1) Glue preparation: Install the stirrer, reflux condenser and constant pressure dropping funnel on a 1000mL four-necked flask, turn on the water bath, raise the temperature to 76°C-78°C, and mix a certain ratio of each Mix monomers, initiators, additives and deionized water, add the uniformly mixed solution into the constant pressure dropping funnel, when the temperature reaches the set temperature, add 1 / 3 of the mixed solution from the constant pressure dropping funnel As a monomer pre-emulsified solution, stir at a rate of 200r / min at the same time. When there is a reflux phenomenon in the four-necked flask, start to add the remaining mixed solution dropwise, and the dropwise addition is completed within 3.0h-4.5h. Finally, conduct a heat preservation reaction at 82°C to 84°C, which takes about 3 hours, and then cool with cold water. When t...

Embodiment 1

[0041]

[0042] Glue preparation steps: install the stirrer, reflux condenser and constant pressure dropping funnel on a 1000mL four-necked flask, turn on the water bath, and raise the temperature to 76°C-78°C. According to the designed formula, mix various monomers, initiators, additives and deionized water in a certain ratio, and put the evenly mixed solution into the constant pressure dropping funnel. Add 1 / 3 of the mixed solution into the dropping funnel as the monomer pre-emulsified solution, and stir at a speed of 200r / min at the same time. When there is a reflux phenomenon in the four-necked flask, start to drop the remaining mixed solution. The dropwise addition is completed within h-4.5h. After the dropwise addition is completed, carry out a heat preservation reaction at 82°C to 84°C for about 3 hours, and then cool with cold water. When the temperature drops below 40°C, filter with 120 mesh and discharge .

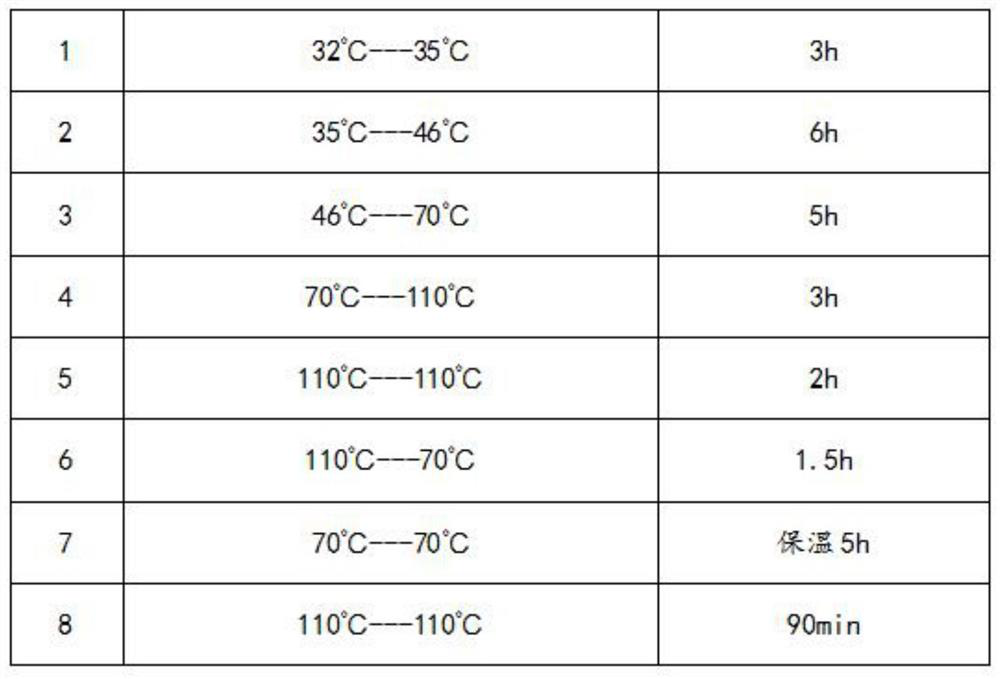

[0043] A preparation process of acrylic resin lens tape...

Embodiment 2

[0045]

[0046] Glue preparation steps: install the stirrer, reflux condenser and constant pressure dropping funnel on a 1000mL four-necked flask, turn on the water bath, and raise the temperature to 76°C-78°C. According to the designed formula, mix various monomers, initiators, additives and deionized water in a certain ratio, and put the evenly mixed solution into the constant pressure dropping funnel. Add 1 / 3 of the mixed solution into the dropping funnel as the monomer pre-emulsified solution, and stir at a speed of 200r / min at the same time. When there is a reflux phenomenon in the four-necked flask, start to drop the remaining mixed solution. The dropwise addition is completed within h-4.5h. After the dropwise addition is completed, carry out a heat preservation reaction at 82°C to 84°C for about 3 hours, and then cool with cold water. When the temperature drops below 40°C, filter with 120 mesh and discharge .

[0047] A preparation process of acrylic resin lens tape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com