Composite coiled tubing with cable oil-water well casing leakage detection system and method

A technology of coiled tubing and composite tubing, which is applied in casing, cable installation in surface conduits, drilling pipes, etc., and can solve problems such as low technical difficulty, reduced oil and water well repair costs, and inability to test lower pipe string packers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

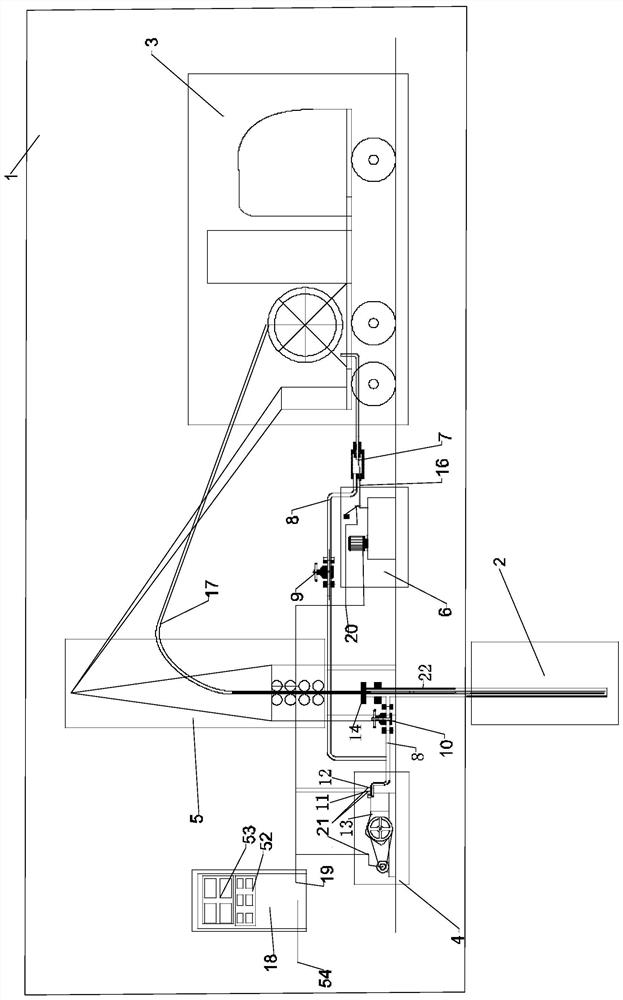

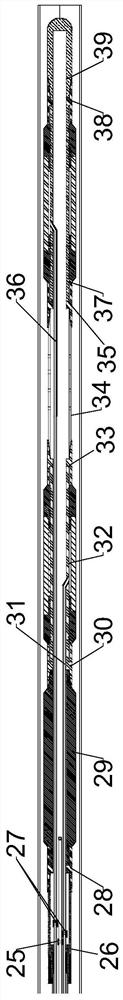

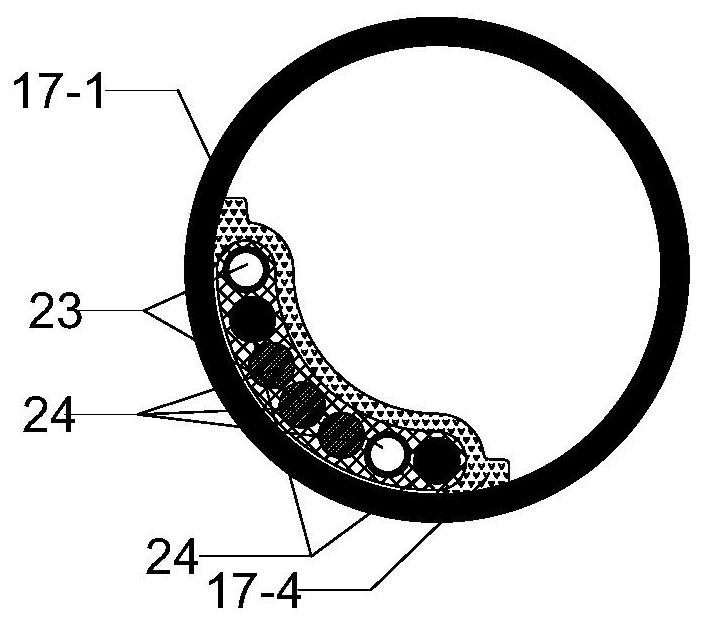

[0074] Such as figure 1 and figure 2 As shown, the composite continuous umbilical cable oil-water well casing leak detection system of the present invention is composed of ground equipment 1 and downhole tool 2;

[0075] The ground equipment 1 includes a coiled tubing vehicle 3, a water injection system 4, a ground hydraulic station 6, a composite umbilical ground separator 7, and a ground control and monitoring system 18; the coiled tubing vehicle 3 is used to put the composite coiled umbilical 17 into the In the downhole tool 2, the composite continuous umbilical 17 is connected to the composite umbilical ground separator 7; the umbilical inside the composite continuous umbilical 17 is separated in the composite umbilical ground separator 7, and the composite umbilical ground separator 7 is injected with water thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com