Ferromagnetic component non-directional alternating-current electromagnetic field stress measurement sensor

An AC electromagnetic field and stress measurement technology, which is applied in the direction of measuring force, measuring device, and measurement of the change force of material magnetic properties caused by applied stress, can solve the problem of large impact on detection effect, expensive equipment, and relatively large impact on detection results. Large and other problems, to achieve the effect of improving measurement efficiency and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

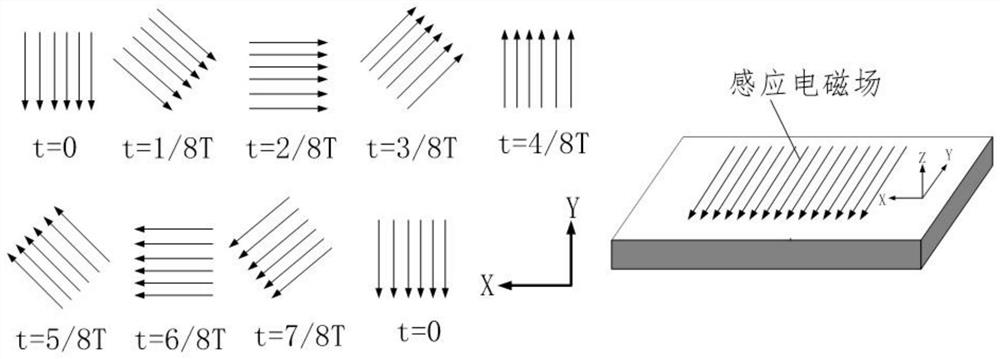

[0037] Example: figure 1 It is a schematic diagram of the induced magnetic field distribution at different times under the orthogonal excitation, refer to figure 1 As shown, the two excitation coils are orthogonal to each other, and the sinusoidal signals with the same frequency and amplitude and 90 degree phase difference constitute the excitation unit. The directional stress has high detection sensitivity.

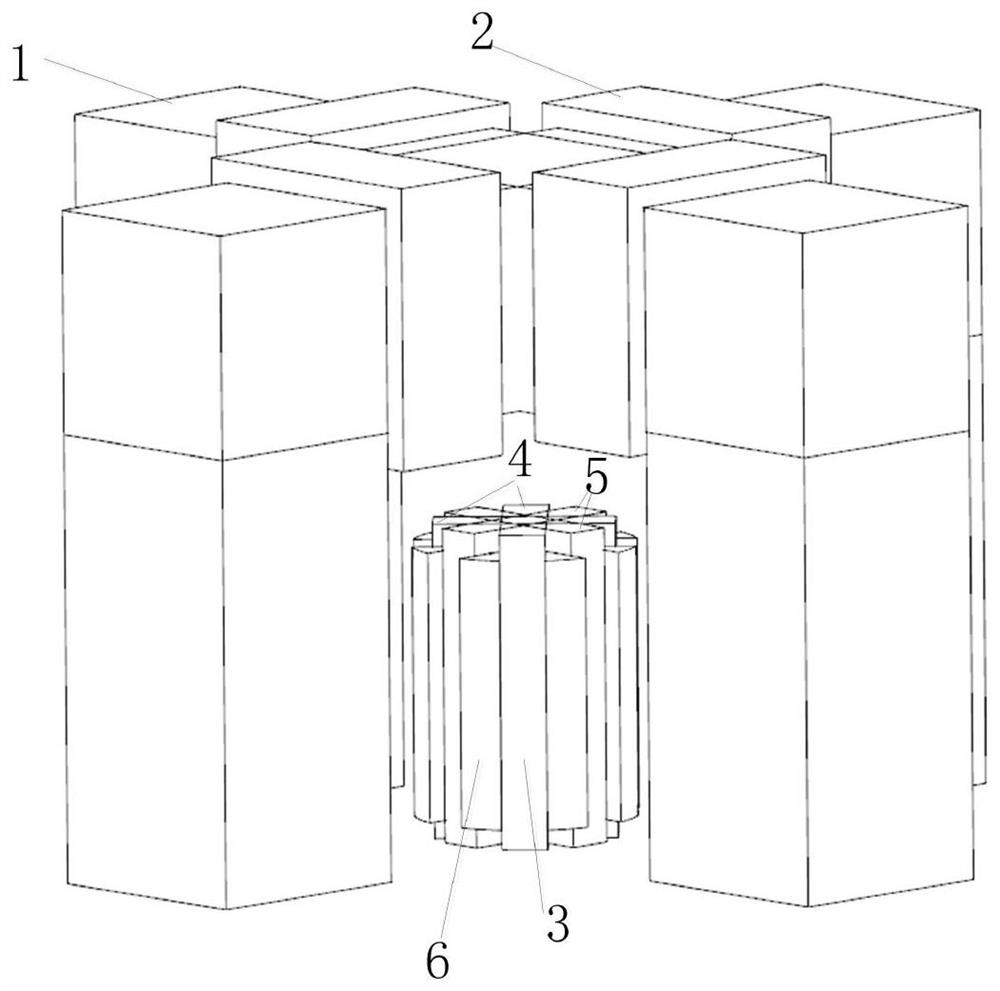

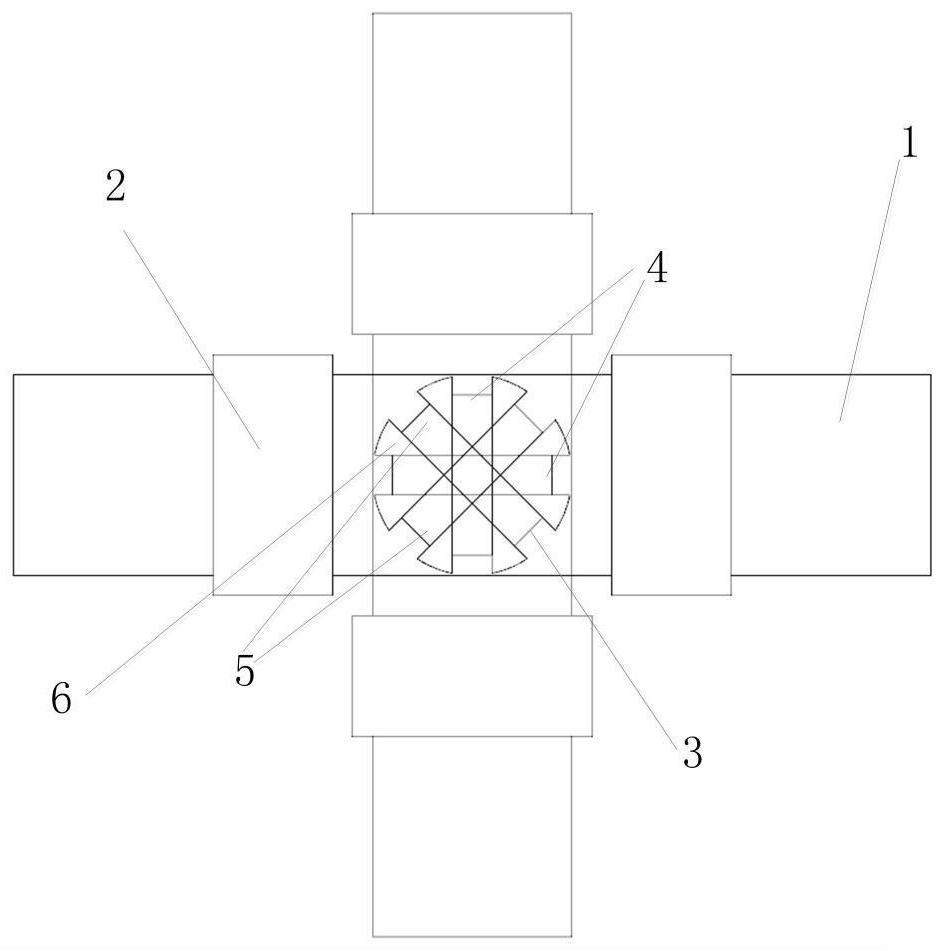

[0038] refer to Figure 2-7 , a ferromagnetic component non-directional differential alternating stress measurement sensor, comprising: an orthogonal excitation module and an orthogonal detection module, the orthogonal excitation module includes two excitation coils 2 and two U-shaped skeletons 1, It is used to induce a uniform alternating electromagnetic field rotating at a uniform speed on the surface of the workpiece to be inspected. The orthogonal detection module includes four detection coils 3 and a detection frame 6 for picking up stress information on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com