Vegetable oil sampling device and sampling method

A technology of vegetable oil and cutting samples, applied in the direction of sampling devices, etc., can solve the problems of unfriendly working environment, low degree of automation, easy entanglement and knotting of cutting ropes, etc., achieve objective and accurate detection results, improve the degree of automation, and meet the requirements of samples representative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

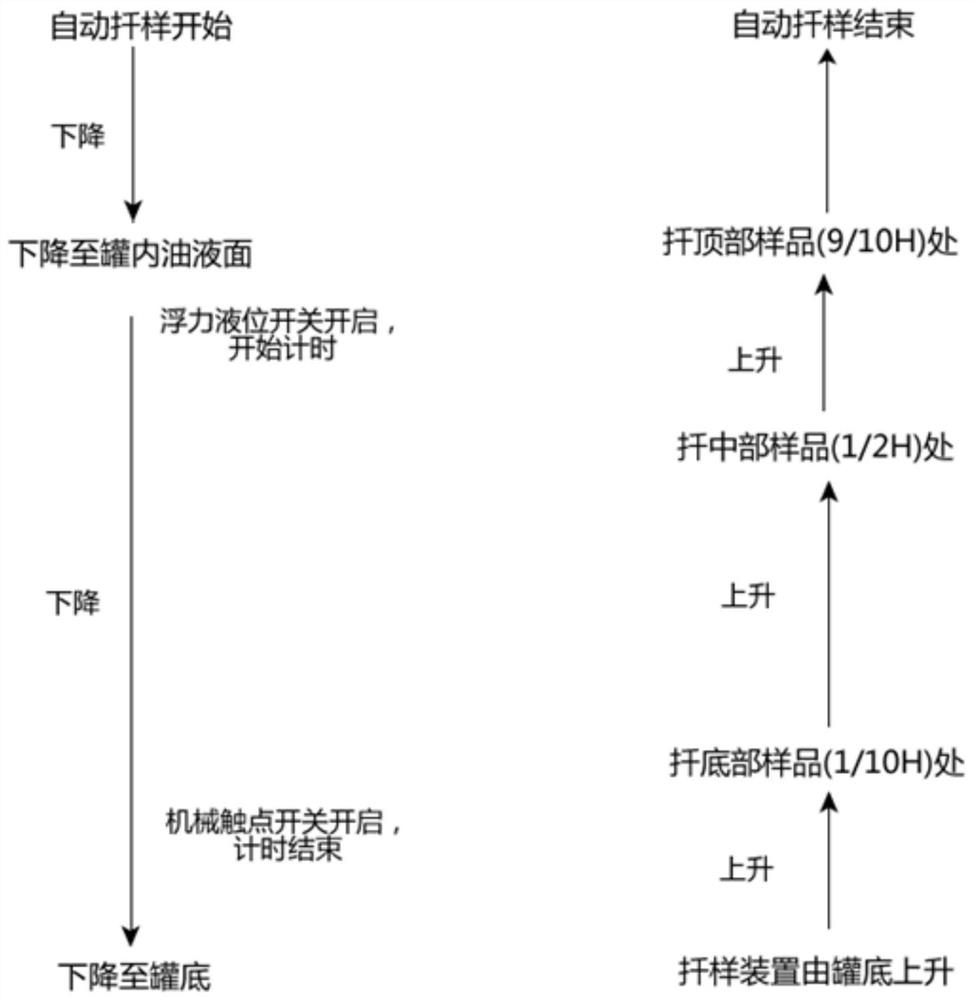

[0075] automatic sampling

[0076] Oil storage tank information: the tank is 11 meters high, 12 meters in diameter, 10 meters high, and has a storage capacity of 1,000 tons.

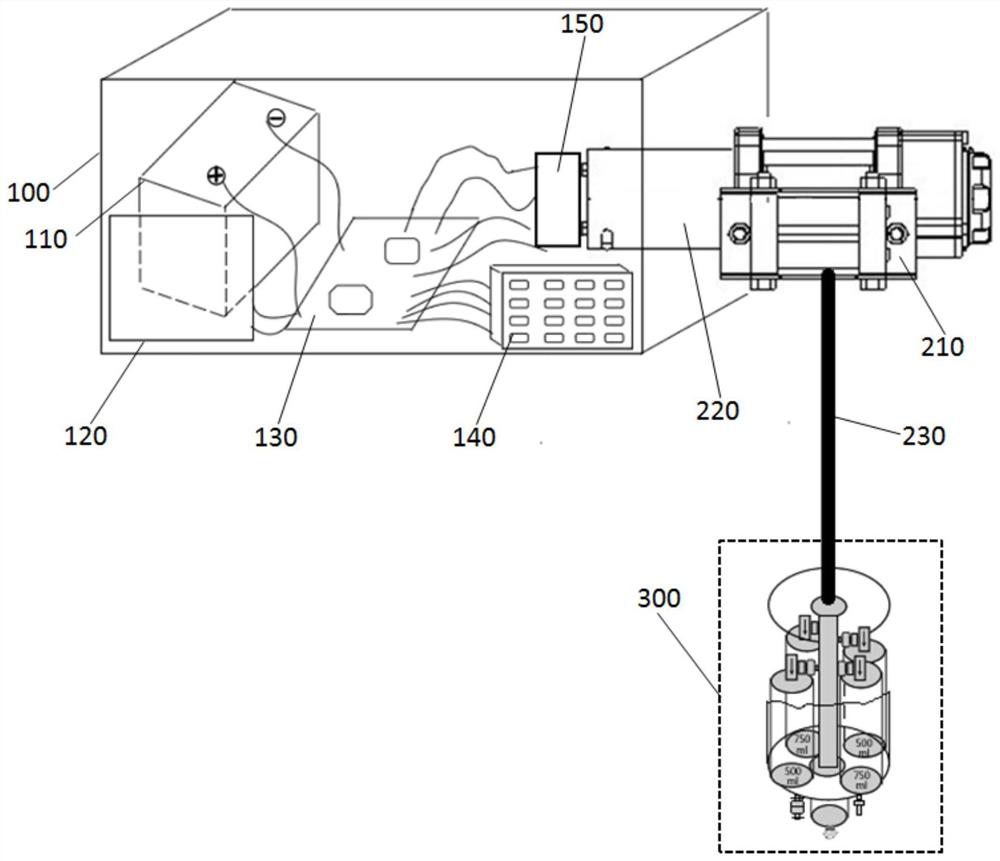

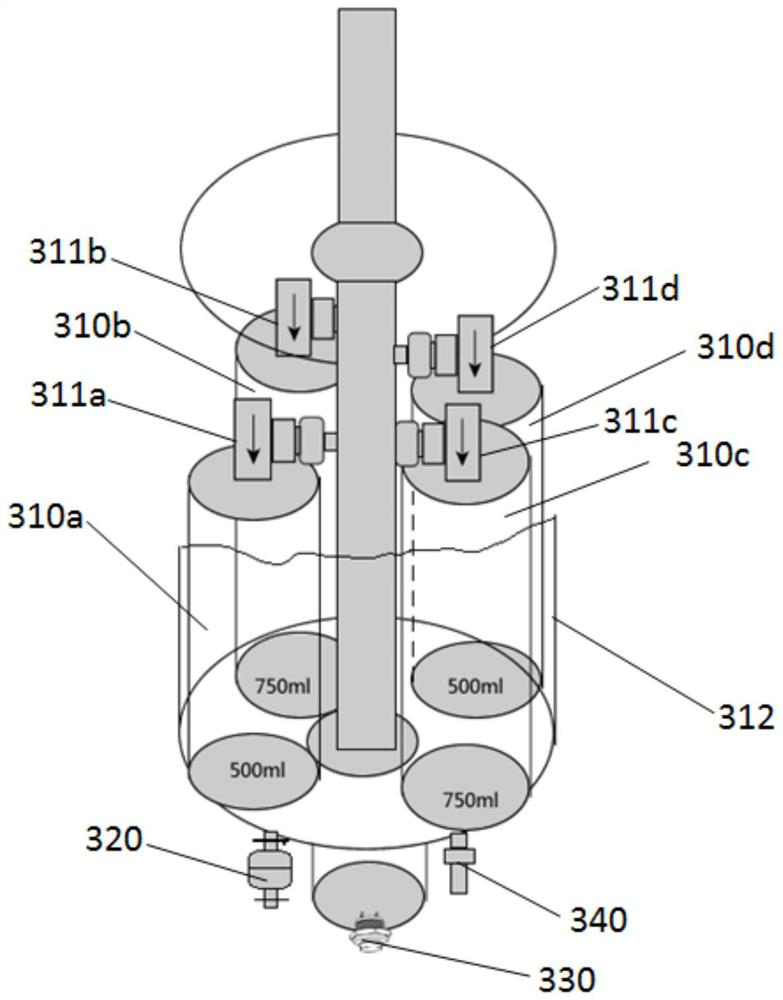

[0077] Oil storage height measurement: fix the control box 100 on the top of the oil tank, start the automatic sampling mode, when the bottom of the sampling device 300 touches the liquid level in the oil tank, the buoyancy liquid level switch 320 at the bottom of the sampling device 300 is turned on, and the control box The meter counter 150 starts to record the descending height of the sampler 300 in the oil tank. When the sampler 300 reaches the bottom of the tank, the mechanical jog switch 330 at the bottom of the sampler 300 is turned on, and an electrical signal is fed back to the integrated circuit board 130. The electric winch 220 suspends work, the control sampler 300 hovers at the bottom of the oil tank, and the meter counter 150 in the control box completes the oil storage height measurement o...

Embodiment 2

[0083] precise sampling

[0084] Oil storage tank information: tank height is 11 meters, diameter is 12 meters, oil storage height is 10 meters, and storage capacity is 1,000 tons; in the precise sampling mode, samples are taken from the upper layer, the middle part, and the bottom layer.

[0085] Oil storage height measurement: Fix the control box 100 on the top of the oil tank and start the precise sampling mode. When the bottom of the sampler 300 touches the liquid level in the oil tank, the buoyancy level switch 320 at the bottom of the sampler 300 is turned on, and the control box The meter counter 150 starts to record the descending height of the sampler 300 in the oil tank. When the sampler 300 reaches the bottom of the tank, the mechanical jog switch 330 at the bottom of the sampler 300 is turned on, and an electrical signal is fed back to the integrated circuit board 130. The electric winch 220 suspends work, the control sampler 300 hovers at the bottom of the oil tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com