Numerical simulation method for oxygen concentration diffusion in oxygen control process of lead-cooled fast reactor

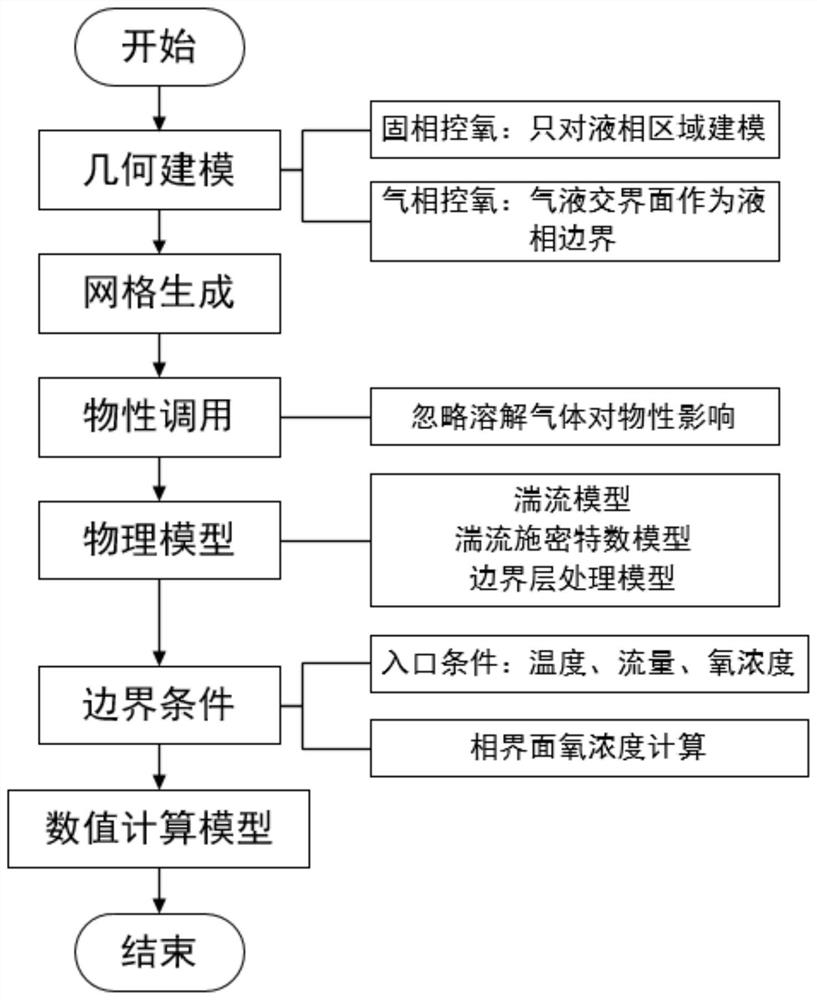

A technology of oxygen concentration and lead cooling, applied in CAD numerical modeling, design optimization/simulation, etc., to achieve the effect of saving computing resources and simplifying the physical phenomenon of oxygen control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0040] A numerical simulation method of oxygen concentration diffusion in the oxygen control process of a lead-cooled fast reactor is used for hydrogen + water gas phase oxygen control. The steps are as follows:

[0041] Step 1: Modeling of the oxygen control device. The calculation model of the oxygen control device only includes the liquid part, and the height of the liquid part is 1 / 3 of the total height. The gas part is simplified to the boundary condition of a given oxygen concentration. It is considered that the gas-liquid two-phase interface remains unchanged, and the gas-liquid two-phase interface Modeled as a fixed wall;

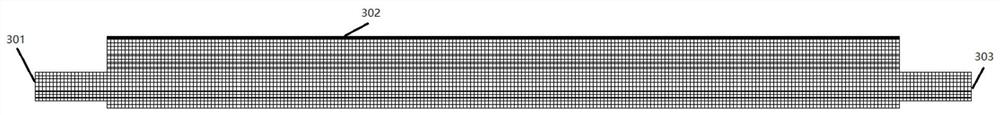

[0042] Step 2: Mesh generation. Such as figure 2 As shown, 301 in the figure is the inlet of the lead-bismuth alloy, 303 is the outlet of the lead-bismuth alloy, and 302 is the vapor-liquid interface, and the mesh is locally densified near the vapor-liquid interface 303 .

[0043] Step 3: Physical property call and calculation model setting of t...

Embodiment example 2

[0076] A numerical simulation method of oxygen concentration diffusion in the oxygen control process of a lead-cooled fast reactor is used for solid-phase oxygen control. The steps are as follows:

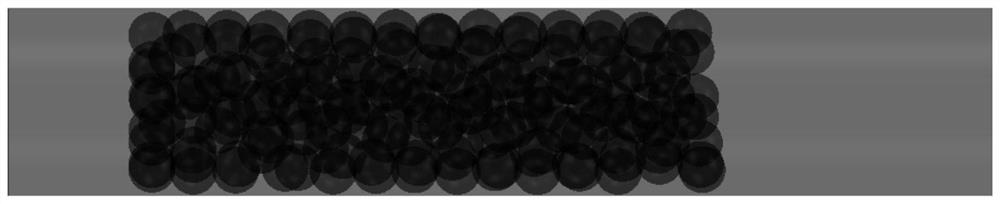

[0077] Step 1: Modeling of the oxygen control device. The calculation model of the oxygen control device only includes the liquid part, and the gas and solid parts are simplified as the boundary conditions of a given oxygen concentration; this example is a solid-phase oxygen control, so the discrete element method is first used to simulate the random accumulation of lead oxide particles, and the accumulation results are used Carry out hydrodynamic modeling, lead oxide particles are not included in the modeling, and only the flow channel of the lead-based coolant is modeled. Such as image 3 As shown, the left side is the inlet section of the lead-bismuth alloy, the right side is the outlet section of the lead-bismuth alloy, and the black shaded sphere indicates the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com