An IGBT device with latch-up resistance

A technology of anti-latch-up and ability, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as threshold voltage influence, device failure, and increased difficulty of P-plus, so as to achieve low equipment requirements, suppress pnpn latch-up, and improve The effect of short-circuit capability and latch-up immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

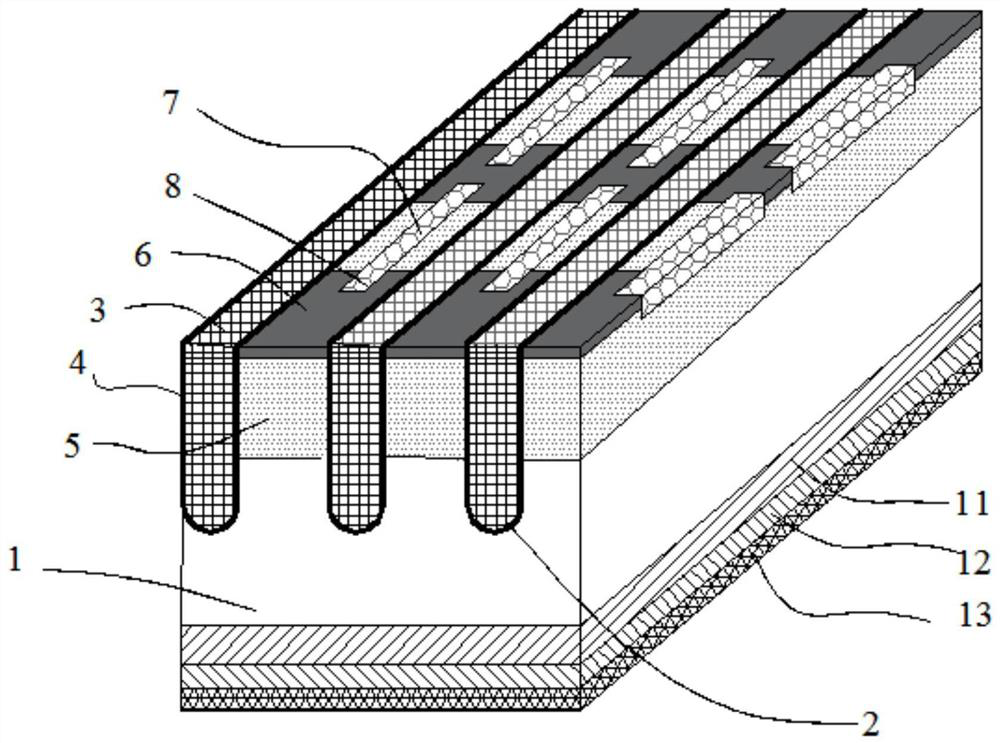

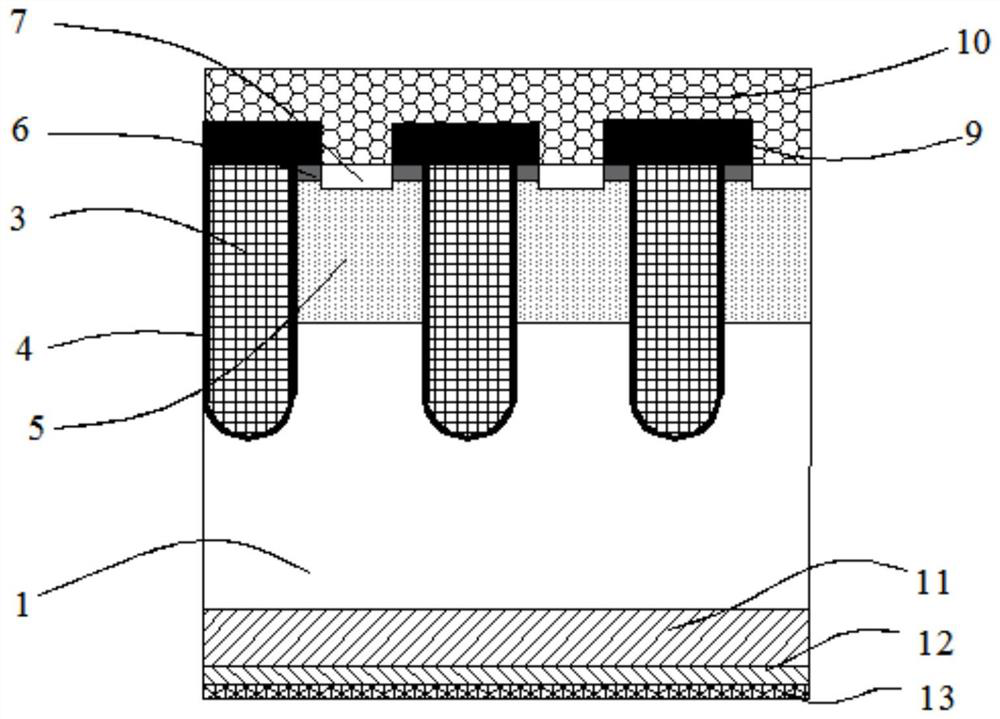

[0027] This embodiment provides an IGBT device structure, please refer to figure 1 and image 3 , which are respectively shown as a perspective view and a cross-sectional view of the IGBT device structure. As shown in the figure, the IGBT device structure includes:

[0028] The segmented N-type source region 6 and the segmented source region contact hole region 7, the N-type source region 6 and the source region contact hole region 7 have an overlapping area 8, the size of the overlapping area 8 is adjustable, and is used to control the introduced The size of the ballast resistor.

[0029] An N-type drift region 1 is set below the P-type body region 5, and a number of trench gates 2 are arranged above the N-type drift region 1. Between the trench gates 2 is a P-type body region 5, and the lower boundary of the P-type body region 5 higher than the bottom of the trench gate 2; the segmented N-type source region 6 is located between the trench gates 3 and embedded above the P-t...

Embodiment 2

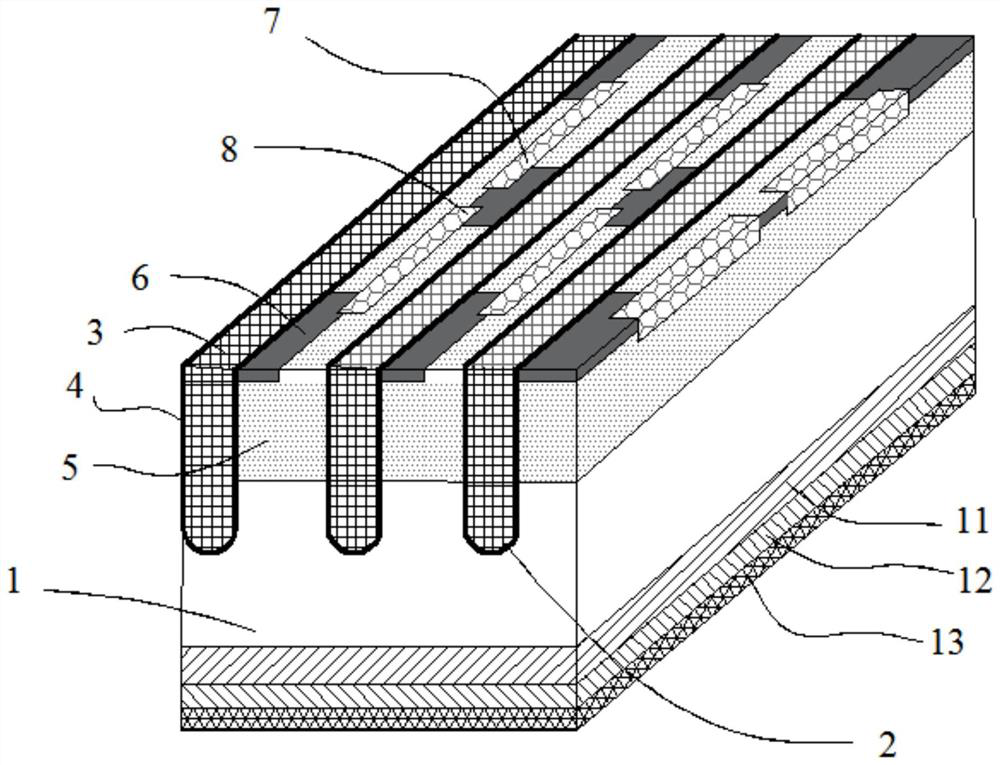

[0037] This embodiment adopts basically the same technical solution as Embodiment 1, except that in Embodiment 1, the width of the N-type source region 6 fills up the width of two adjacent trench gates 2; The segmented N-type source region 6 between the trench gates 2 is only in contact with the trench gate 2 on one side, that is, the width of the N-type source region 6 does not fill up two adjacent trench gates 2; Two adjacent segmented N-type source regions 6 between two trench gates 2 are in contact with trench gates 2 on different sides. In Embodiment 1, the length of the overlapping region 8 of the source contact hole region 7 and the N-type source region 6 is 1 μm, while in this embodiment, the length of the overlapping region 8 of the source contact hole region 7 and the N-type source region 6 The length is 2 μm.

[0038] see figure 2 , which is a perspective view of the structure of the IGBT device in this embodiment, as shown in the figure, the length of the overla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com