Electrical control case with heat dissipation function and using method thereof

A technology of electrical control and chassis, applied in the direction of electrical components, substation/power distribution device casing, substation/switch layout details, etc., can solve problems such as difficult arrangement, poor heat dissipation, messy lines, etc., to improve heat conduction effect, improve Cooling effect, rapid heat dissipation and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

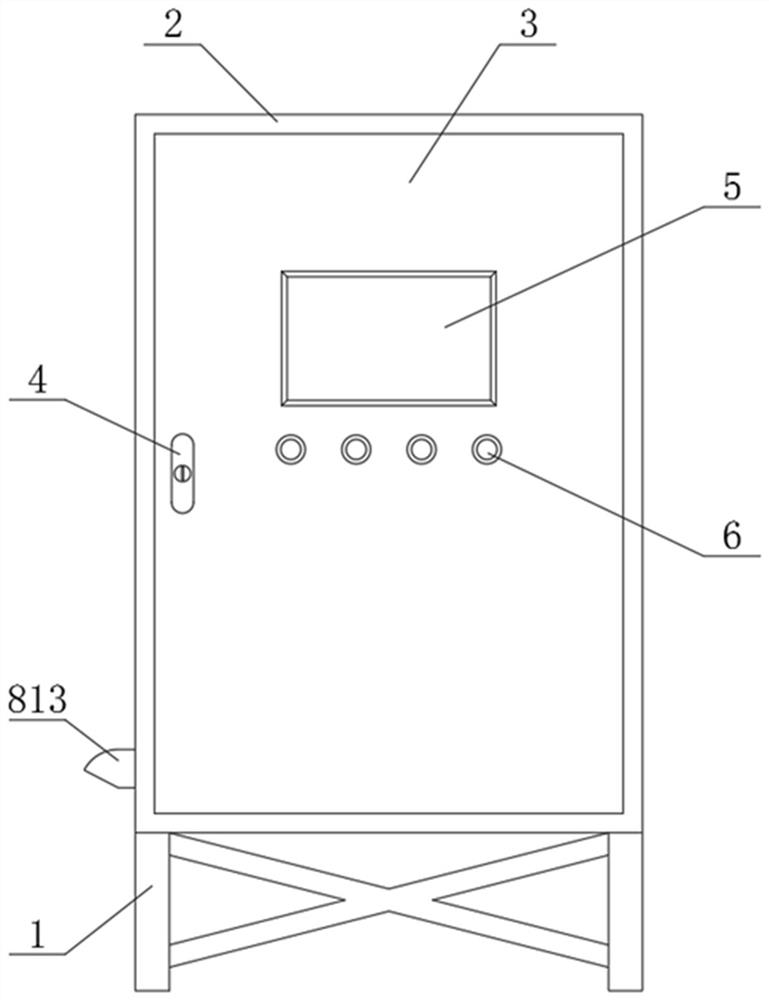

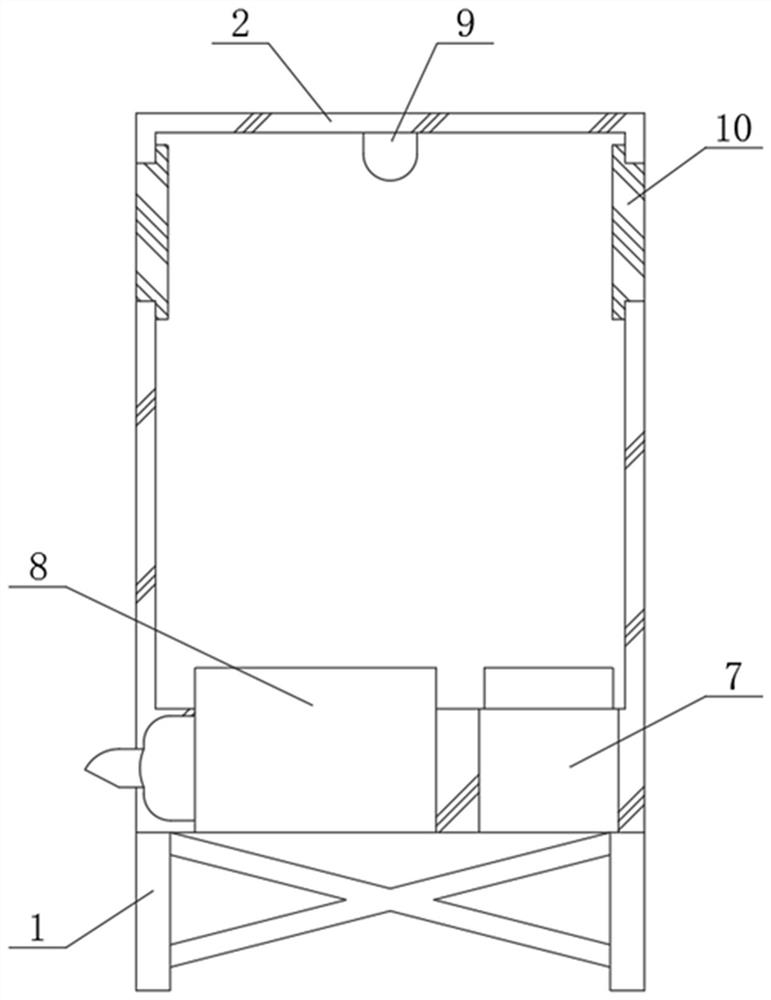

[0036] see figure 1 , figure 2 , Figure 4 , Figure 7 , Figure 13 , the present invention provides a technical solution:

[0037] An electrical control box with heat dissipation function and its use method, comprising an electrical control box base 1, an electrical control box body 2 is fixedly connected to the outer top of the electrical control box base 1, and the front inner side of the electrical control box body 2 is rotatably connected There is an electric control cabinet revolving door 3, a mechanical lock assembly 4 is arranged on the inner side of the left end of the electric control cabinet revolving door 3, and a heat dissipation control host and a display screen assembly 5 are arranged on the inside of the top end of the electric control cabinet revolving door 3. This setting can Make the heat dissipation function of the heat dissipation control host and the display screen assembly 5 control device run and display the heat dissipation data. The control butto...

Embodiment 2

[0041] see figure figure 1 , figure 2 , Figure 4 , Figure 7 , Figure 13 , the present invention provides a technical solution:

[0042] An electrical control cabinet with heat dissipation function and its use method, the same parts in embodiment 2 as in embodiment 1 will not be repeated in the present invention, and the difference lies in the working process.

[0043] Work flow: the present invention needs to be powered by an external power supply before use. When the temperature and humidity sensor assembly 9 detects that the humidity inside the electrical control chassis 2 is higher than 60%, the heat dissipation control host and display screen assembly 5 will Automatically energize the brake motor 811 in the positive direction. After the brake motor 811 is energized in the forward direction, it will drive the rotating baffle 812 to rotate clockwise, so that the rotating baffle 812 will rotate and contact the upper side of the total air intake head 813, thereby block...

Embodiment 3

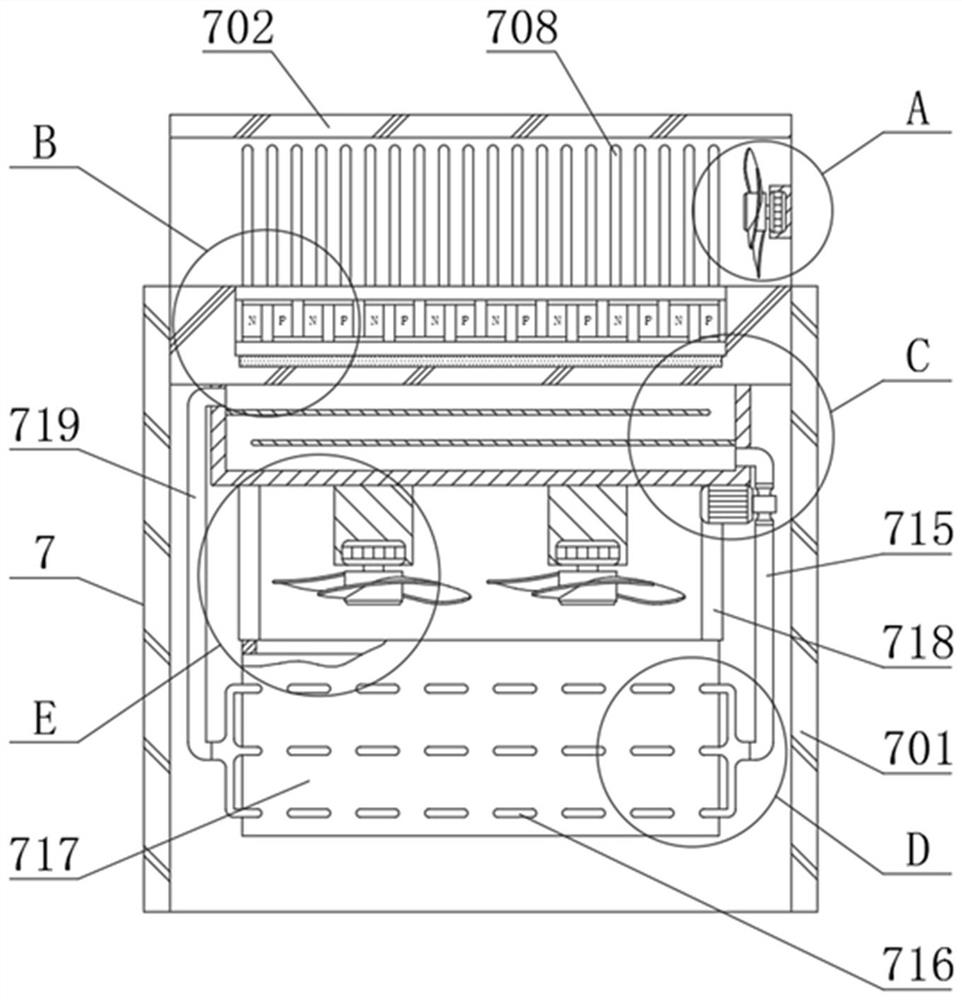

[0045] see figure 1 , figure 2 , image 3 , Figure 5 , Figure 6 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , the present invention provides a technical solution:

[0046] An electrical control cabinet with heat dissipation function and its use method, the same parts in embodiment 3 as in embodiment 1-2 will not be repeated in the present invention, and the difference lies in the work flow.

[0047] Work process: the present invention needs to be powered by an external power supply before use, and the temperature and humidity inside the electrical control cabinet body 2 can be detected by the temperature and humidity sensor assembly 9. When the temperature and humidity sensor assembly 9 detects the temperature and humidity of the electrical control cabinet When the temperature inside the body 2 is higher than 45 degrees, if the temperature cannot be lowered for 5 minutes by the ordinary cooling method, the Peltier sensor 707 is automatically energi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com