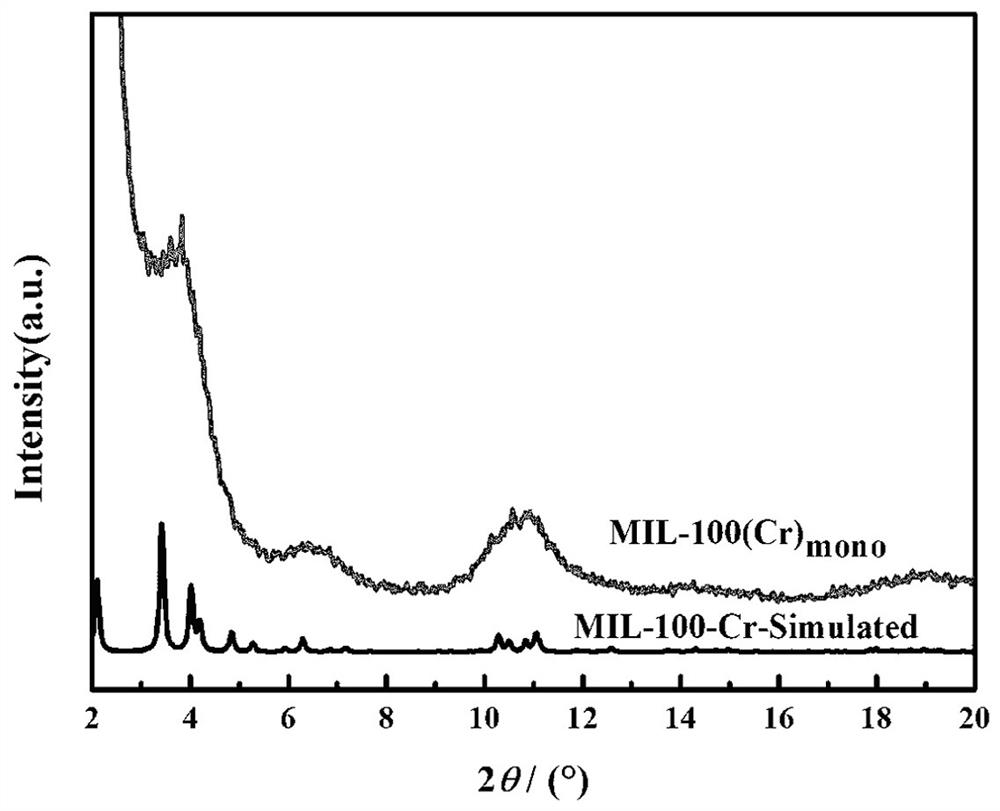

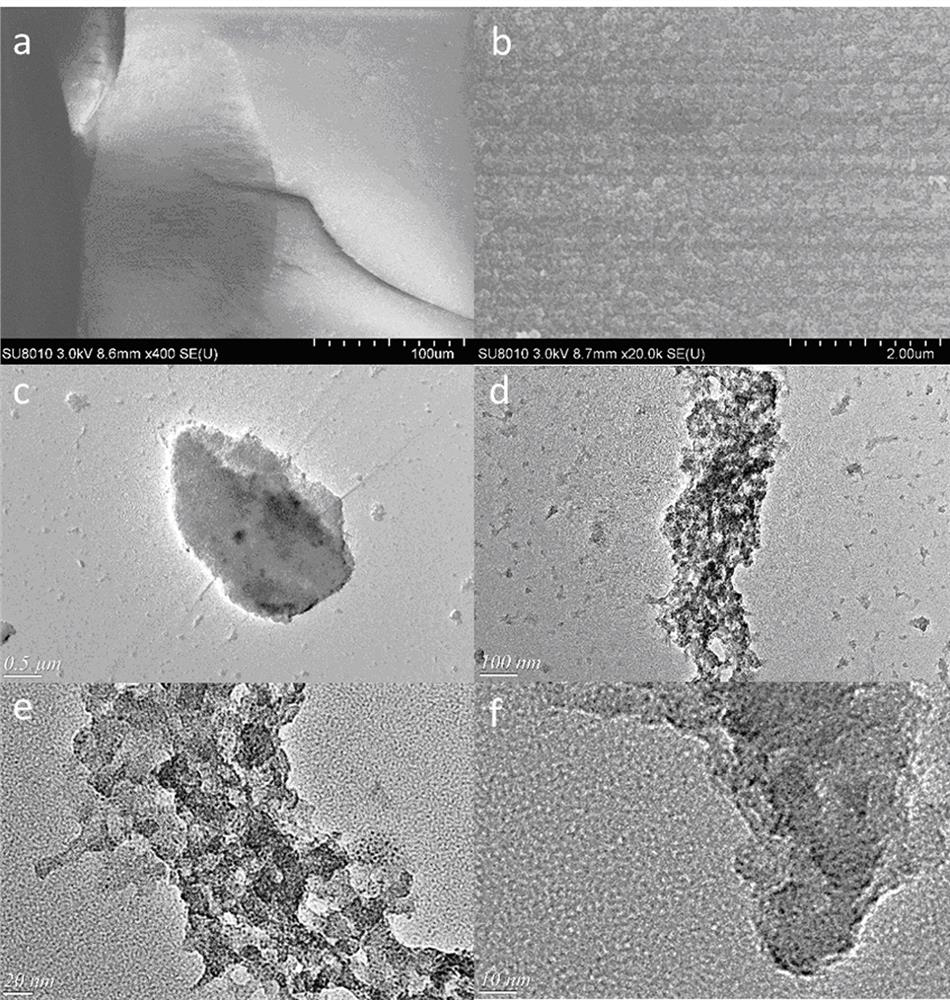

Method for synthesizing MIL-100Cr integral material by sol-gel method

A sol-gel method and monolithic technology, which is applied in the field of sol-gel synthesis of molding-free MIL-100Cr monolithic materials, can solve the problems of shortage of molding technology, large pollution, high risk, etc., and achieve green and efficient synthesis, large-scale industry The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]A kind of sol-gel method is synthesized the method for exempting molding MIL-100Cr integral material, and its steps are:

[0036] (1) 0.5329 g CrCl 3 ·6H 2 O, 0.22 g H 3 Add BTC and 30 mL deionized water to a 100 mL beaker in sequence, and stir at room temperature for 30 min at 700 r / min to obtain a clear solution;

[0037] (2) Transfer the clarified solution obtained in step (1) to a 100 mL polytetrafluoroethylene container, place it in a stainless steel reaction kettle, and seal it, then place the sealed reaction kettle in a constant temperature oven, and set the temperature of the oven to After heating at 220°C for 9 hours, the reactor was cooled to room temperature, and the reactor was opened to obtain a wet gel that no longer had fluidity. The heating rate and cooling rate were both 5°C / min;

[0038] (3) Transfer the wet gel obtained in step (2) to a 50mL beaker, and age at room temperature (25°C) for 7 days to obtain the MIL-100Cr dry gel precursor;

[0039] (4...

Embodiment 2

[0063] A kind of sol-gel method is synthesized the method for exempting molding MIL-100Cr integral material, and its steps are:

[0064] (1) 0.5595 g CrCl 3 ·6H 2 O, 0.24 g H 3 Add BTC and 27 mL of deionized water to a 100 mL beaker in turn, and stir at room temperature for 30 min at 700 r / min to obtain a clear solution;

[0065](2) Transfer the clarified solution obtained in step (1) to a 100 mL polytetrafluoroethylene container, place it in a stainless steel reaction kettle, and seal it, then place the sealed reaction kettle in a constant temperature oven, and set the temperature of the oven to After heating for 11 hours at 200°C, the reaction kettle was cooled to room temperature, and the reaction kettle was opened to obtain a wet gel that no longer had fluidity. The heating rate and cooling rate were both 5°C / min;

[0066] (3) Transfer the wet gel obtained in step (2) to a 50mL beaker, and age at room temperature (25°C) for 7 days to obtain the MIL-100Cr dry gel precurs...

Embodiment 3

[0069] A kind of sol-gel method is synthesized the method for exempting molding MIL-100Cr integral material, and its steps are:

[0070] (1) 0.5062 g CrCl 3 ·6H 2 O, 0.20 g H 3 Add BTC and 32 mL deionized water to a 100 mL beaker in sequence, and stir at room temperature for 30 min at 700 r / min to obtain a clear solution;

[0071] (2) Transfer the clarified solution obtained in step (1) to a 100 mL polytetrafluoroethylene container, place it in a stainless steel reaction kettle, and seal it, then place the sealed reaction kettle in a constant temperature oven, and set the temperature of the oven to After heating for 7 hours at 240°C, the reactor was cooled to room temperature, and the reactor was opened to obtain a wet gel that no longer had fluidity. The heating rate and cooling rate were both 5°C / min;

[0072] (3) Transfer the wet gel obtained in step (2) to a 50mL beaker, and age at room temperature (25°C) for 7 days to obtain the MIL-100Cr dry gel precursor;

[0073] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com