Click-crosslinked fluorescent polymer and its preparation and application

A fluorescent polymer and fluorescent technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of automatic detection limitations, etc., and achieve the effect of rapid and efficient response, simple method, and unique fluorescent characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

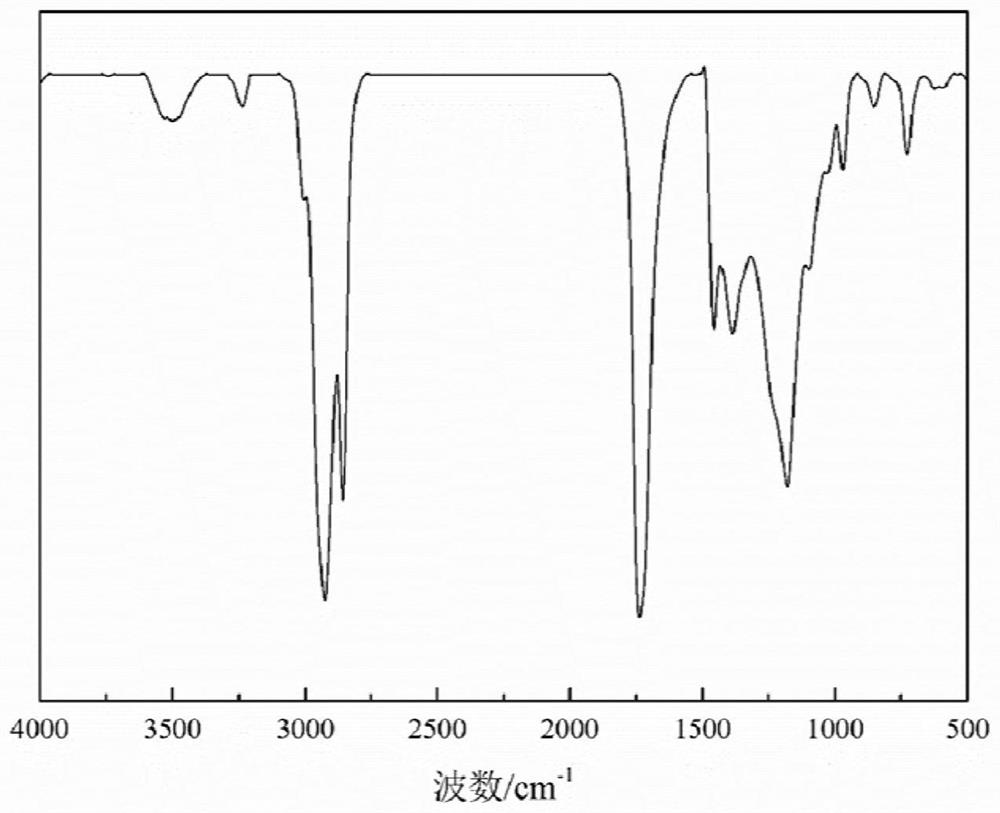

[0036] (1) Weigh 10.374g of citric acid and 37.337g of castor oil in a 500ml round-bottomed flask, raise the temperature to 140°C under stirring, connect to a water pump to evacuate, and react for 2h; lower the temperature to 120°C, add 0.654g half For cystine, replace it with an oil pump to evacuate, control the reaction temperature to 120°C, and continue the reaction for 4 hours, then stop heating and let the polymer cool down naturally;

[0037] (2) The cooled polymer in (1) is equally divided into two parts, respectively placed in two 250ml three-necked flasks, and 0.091g of 1-pentyn-3-alcohol and 0.094g of 2-azidoethanol, the temperature was raised to 60°C under stirring, reacted for 3h, and cooled to obtain fluorescent polyesters containing azido groups and fluorescent polyesters containing alkynyl groups (two kinds of fluorescent polyesters containing different click groups). polymer);

[0038] (3) 1ml of copper sulfate solution (containing 0.05g of copper sulfate) and...

Embodiment 2

[0040] (1) Weigh 10.374g of citric acid and 37.337g of castor oil in a 500ml round-bottomed flask, raise the temperature to 140°C under stirring, connect to a water pump to evacuate, and react for 2h; lower the temperature to 120°C, add 0.654g half For cystine, replace it with an oil pump to evacuate, control the reaction temperature to 120°C, and continue the reaction for 4 hours, then stop heating and let the polymer cool down naturally;

[0041] (2) The polymer after cooling in (1) is divided into two parts equally, is placed in two 250ml three-necked flasks respectively, in two three-necked flasks, add 1-pentyne-3 alcohol 0.188g and 2 -Azidoethanol 0.188g, raise the temperature to 60°C under stirring, react for 3h, and cool to obtain fluorescent polyester containing azido group and fluorescent polyester containing alkyne group (two polymers containing different click groups) things);

[0042] (3) 1ml of copper sulfate solution (containing 0.05g of copper sulfate) and 1ml ...

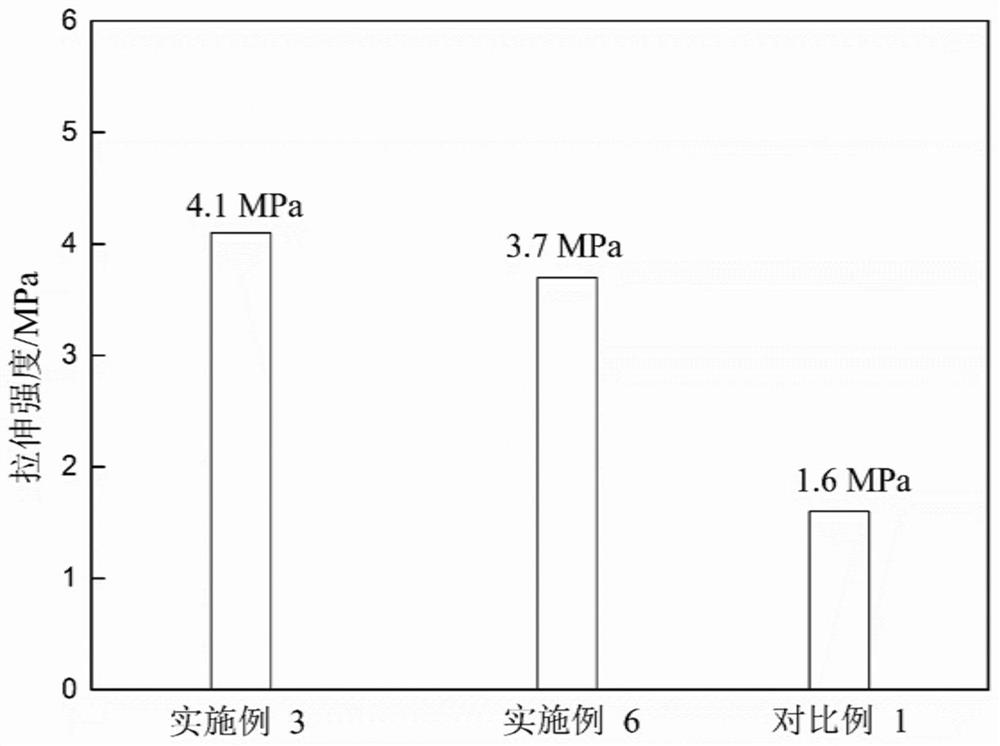

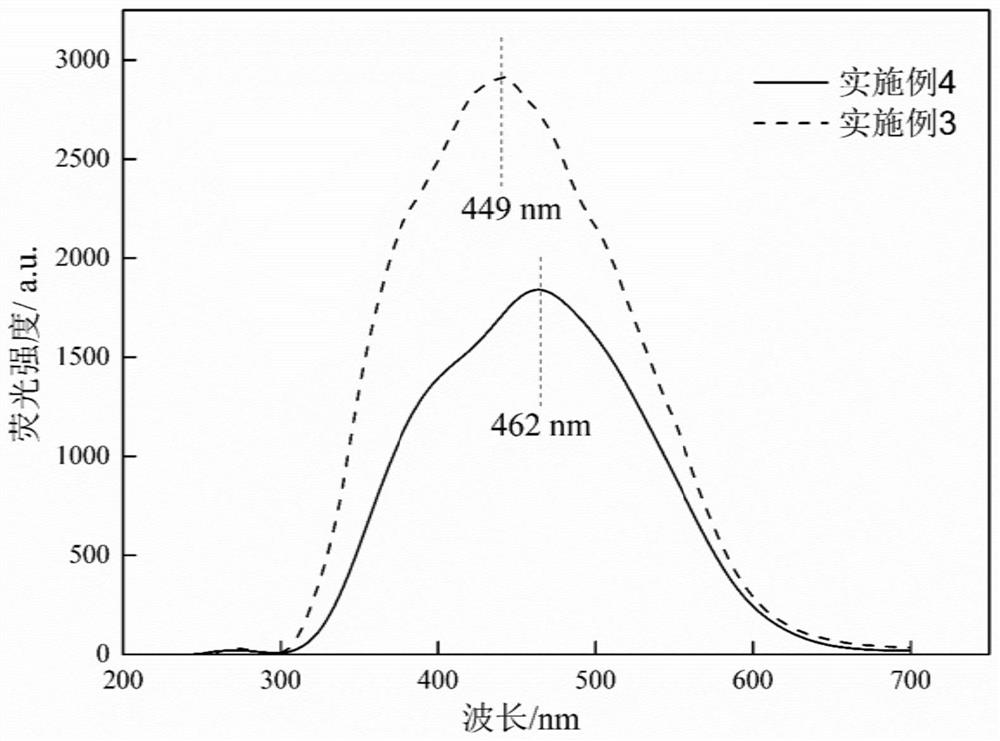

Embodiment 3

[0044] (1) Weigh 10.374g of citric acid and 37.337g of castor oil in a 500ml round-bottomed flask, raise the temperature to 140°C under stirring, connect to a water pump to evacuate, and react for 2h; lower the temperature to 120°C, add 0.654g half For cystine, replace it with an oil pump to evacuate, control the reaction temperature to 120°C, and continue the reaction for 4 hours, then stop heating and let the polymer cool down naturally;

[0045] (2) The polymer after cooling in (1) is divided into two parts equally, is placed in two 250ml three-necked flasks respectively, in two three-necked flasks, add 1-pentyne-3 alcohol 0.273g and 2 - Azidoethanol 0.282g, raise the temperature to 60°C under stirring, and react for 3h to obtain fluorescent polyesters containing azido groups and fluorescent polyesters containing alkyne groups (two polymers containing different click groups) ;

[0046] (3) 1ml of copper sulfate solution (containing 0.05g of copper sulfate) and 1ml of sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com