Cerium-based nano composite material and preparation method and application thereof

A nanocomposite material, cerium-based technology, applied in the direction of analyzing materials, material excitation analysis, material analysis through optical means, etc., can solve problems such as limiting biological applications, achieve reasonable process design, promote wound healing, and good photostability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

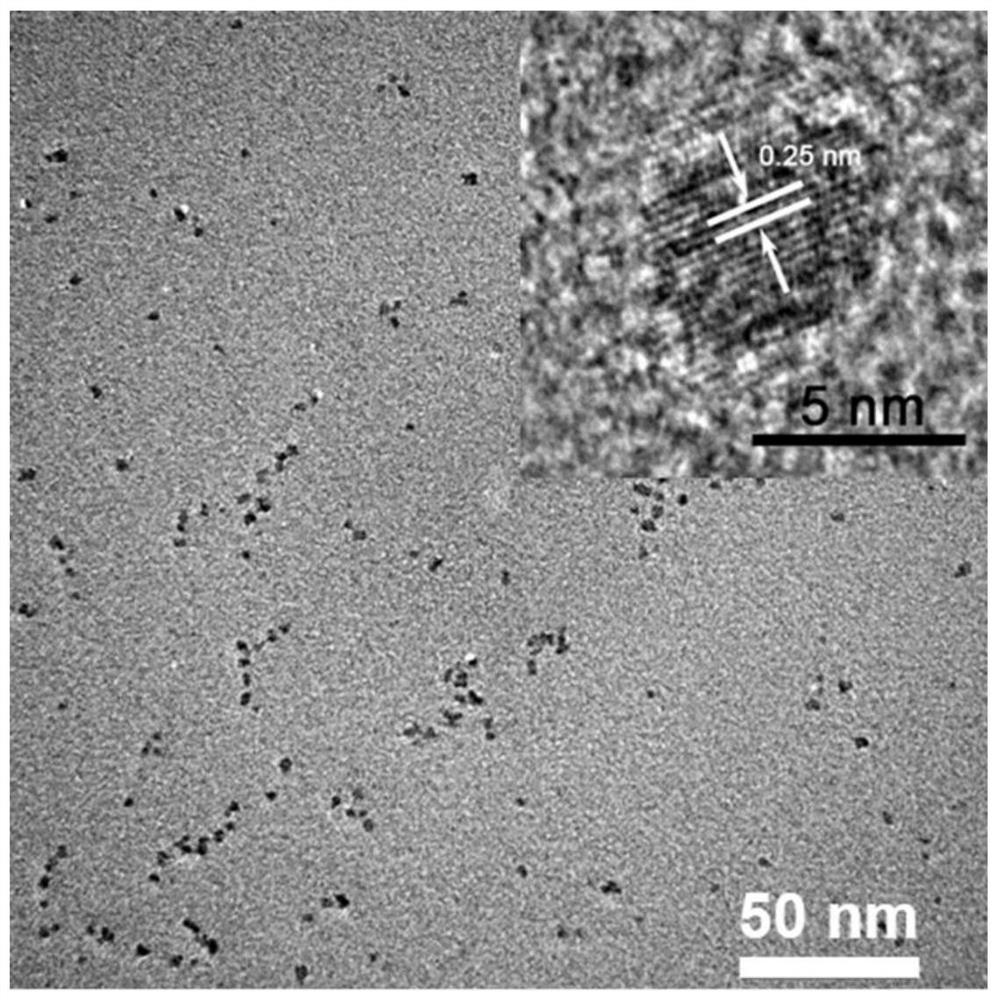

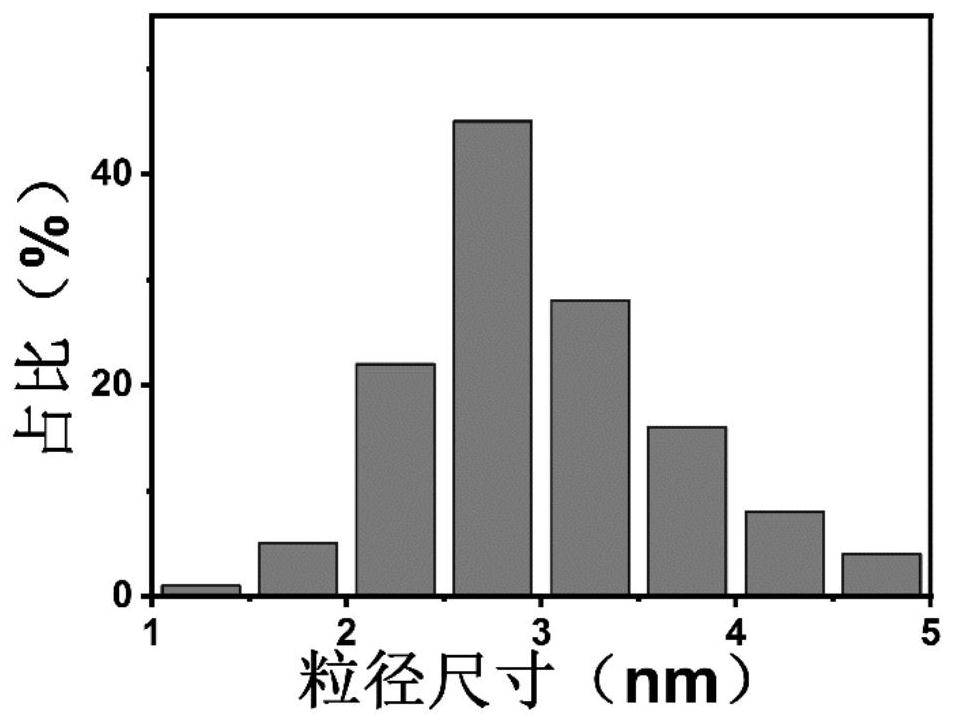

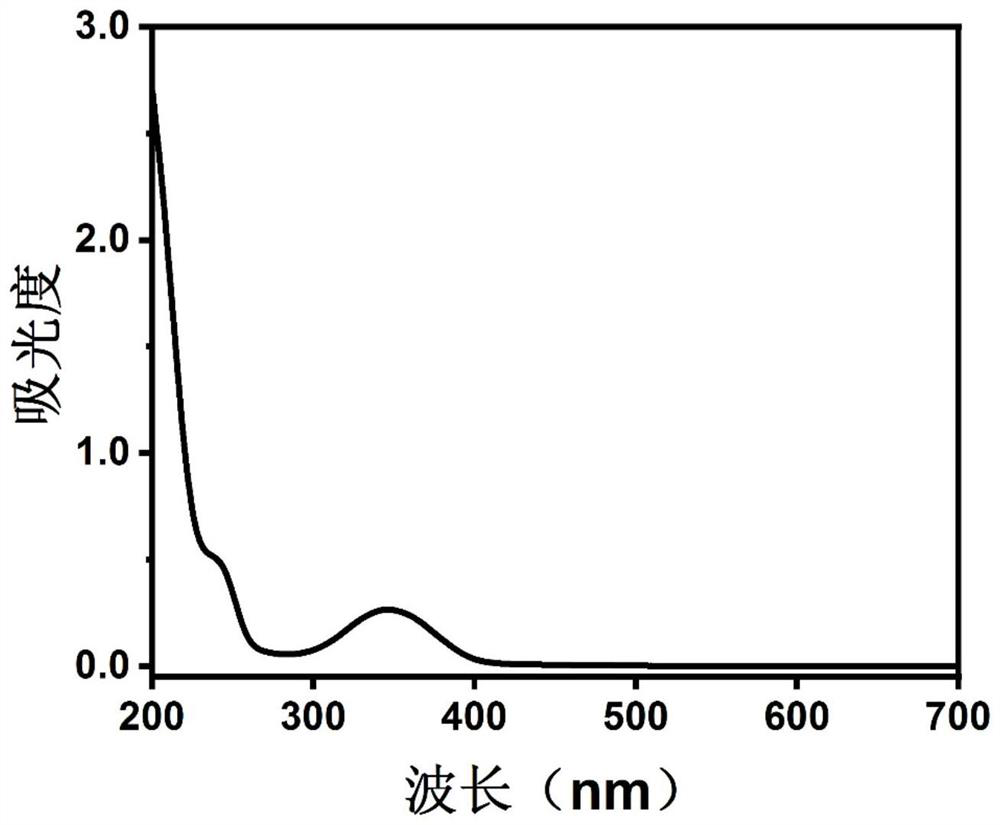

[0041] The preparation method of cerium-containing carbon quantum dot nanocomposite material 1 comprises the following steps:

[0042]Step 1: Weigh 0.800g of cerium nitrate hexahydrate, dissolve 1.062g of citric acid in 20mL of deionized water, stir for 1 hour to dissolve, then measure 1.11mL of ethylenediamine (the molar ratio of ethylenediamine to citric acid is 3:1 ), added in the above mixed solution, fully mixed;

[0043] Step 2: Add the mixed solution into a polytetrafluoroethylene reactor, react at 200°C for 4 hours, and naturally cool to room temperature to obtain a product solution;

[0044] Step 3: Centrifuge the product solution at a speed of 2000 rpm to remove insoluble substances in the product solution, dialyze the supernatant with a dialysis bag with a molecular weight of 1000Da for 5 days to remove unreacted small molecular substances, and then The dialyzed solution was freeze-dried to obtain a brown-red powdery cerium-containing carbon quantum dot nanocomposi...

Embodiment 2

[0046] The preparation method of cerium-containing carbon quantum dot nanocomposite material 2 comprises the following steps:

[0047] Step 1: Weigh 0.800g of cerium nitrate hexahydrate, dissolve 1.062g of citric acid in 20mL of deionized water, stir for 1 hour to dissolve, then measure 0.37mL of ethylenediamine (the molar ratio of ethylenediamine to citric acid is 1:1 ), added in the above mixed solution, fully mixed;

[0048] Step 2: Add the mixed solution into a polytetrafluoroethylene reactor, react at 200°C for 4 hours, and naturally cool to room temperature to obtain a product solution;

[0049] Step 3: Centrifuge the product solution at a speed of 2000 rpm to remove insoluble substances in the product solution, dialyze the supernatant with a dialysis bag with a molecular weight of 1000Da for 5 days to remove unreacted small molecular substances, and then The dialyzed solution was freeze-dried to obtain a brownish-red powdery cerium-containing carbon quantum dot nanocom...

Embodiment 3

[0051] The preparation method of cerium-containing carbon quantum dot nanocomposite material 3 comprises the following steps:

[0052] Step 1: Weigh 0.800g cerium nitrate hexahydrate, dissolve 1.062g citric acid in 20mL deionized water, stir for 1 hour to dissolve, then measure 1.48mL ethylenediamine (the molar ratio of ethylenediamine to citric acid is 4:1 ), added in the above mixed solution, fully mixed;

[0053] Step 2: Add the mixed solution into a polytetrafluoroethylene reactor, react at 200°C for 4 hours, and naturally cool to room temperature to obtain a product solution;

[0054] Step 3: Centrifuge the product solution at a speed of 2000 rpm to remove insoluble substances in the product solution, dialyze the supernatant with a dialysis bag with a molecular weight of 1000Da for 5 days to remove unreacted small molecular substances, and then The dialyzed solution was freeze-dried to obtain a brown-red powdery cerium-containing carbon quantum dot nanocomposite material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com