High-hardness wear-resistant cast iron and preparation method thereof

A technology of wear-resistant cast iron and high hardness, which is applied in the field of metal materials, can solve the problems of poor wear resistance of materials, and achieve the effect of improving hardness and wear resistance, high hardness and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment the present invention is described in further detail.

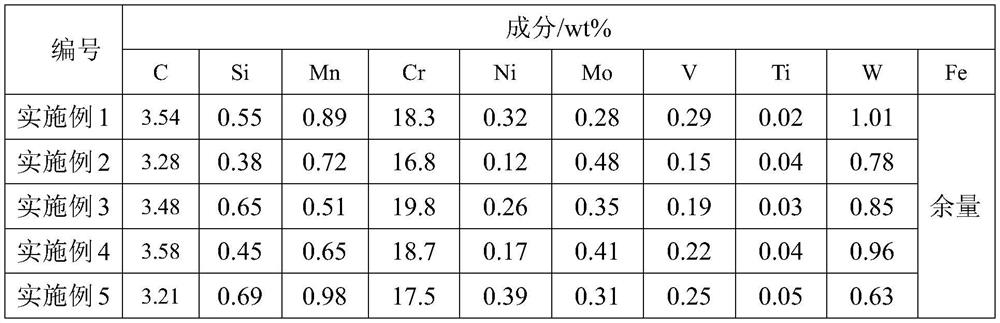

[0031] Embodiments 1 to 5 are the components of the high-hardness wear-resistant cast iron of the present invention, and the specific components are shown in Table 1. The preparation process of the cast iron is as follows:

[0032] 1) Smelting: Manganese, chromium, vanadium, molybdenum, titanium, and tungsten are added to the smelting furnace in the form of their respective master alloys ferromanganese, ferrochromium, ferrovanadium, ferromolybdenum, ferrotitanium and ferrotungsten, and nickel is in the form of pure nickel Adding; first add ferromolybdenum, ferrotungsten, cast iron, steel and some ferrochrome and ferrovanadium to the bottom of the crucible of the induction melting furnace. Ferro-vanadium and the remaining ferrochrome and ferro-vanadium, and finally ferromanganese.

[0033] 2) Pouring; the temperature of the melt is controlled at 1500-1600°C, the pouring temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com