Downhole layered reinforcing method of closed bad drilled holes

A bad sealing agent technology, applied in the direction of earthwork drilling, sealing/packing, wellbore/well components, etc., can solve problems such as the inability to find hole marks on the ground, potential safety hazards, and inability to unseal the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The underground layered reinforcement method of the poorly sealed borehole takes the poorly sealed borehole 1 in the Tangjiahui Coal Mine as an example, and the poorly sealed borehole 1 is named D12.

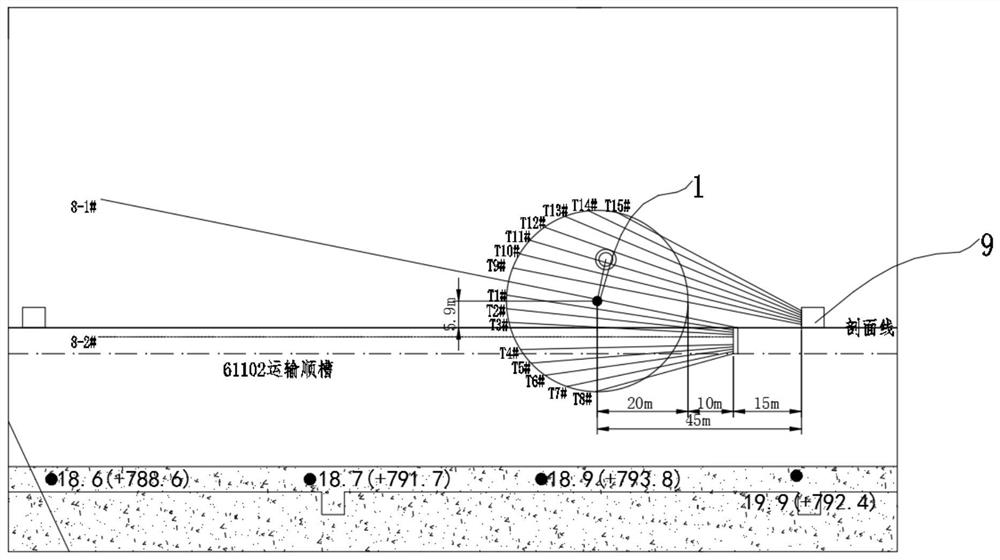

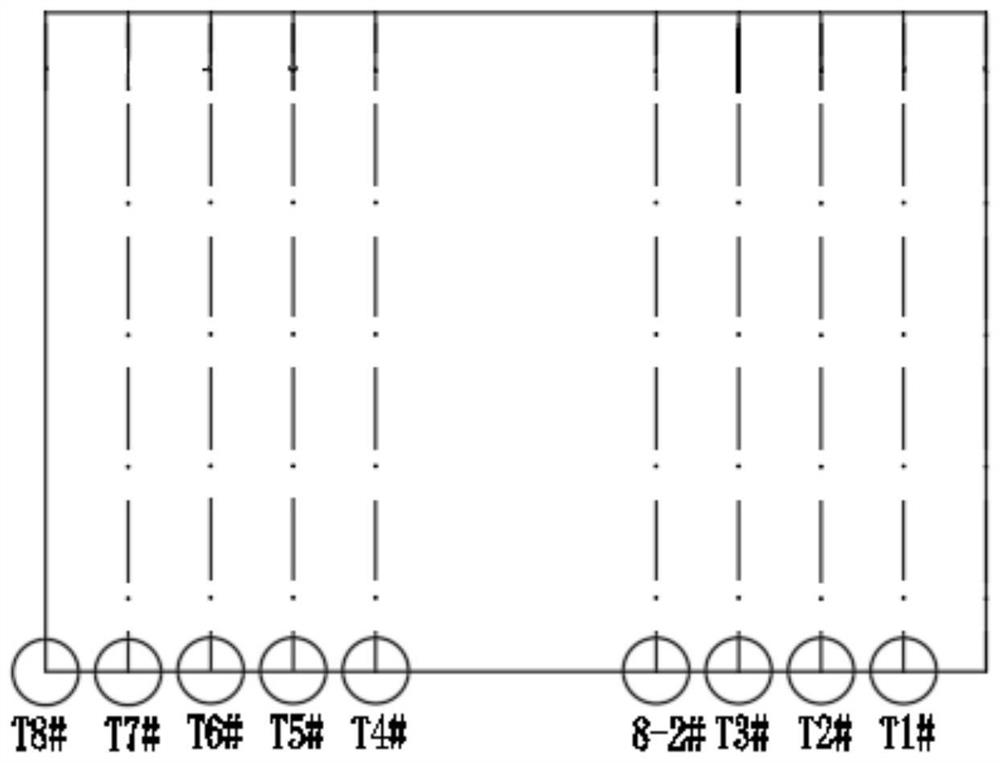

[0041] Layout of exploratory boreholes: The exploratory boreholes are arranged in groups, forming a fan shape on the horizontal plane in front of the roadway. The position of the end hole of the exploratory borehole meets the horizontal distance of 3m. The depth is 20m, and the two layers of the coal floor and the top section of the Austrian ash layer are respectively explored and reinforced by grouting.

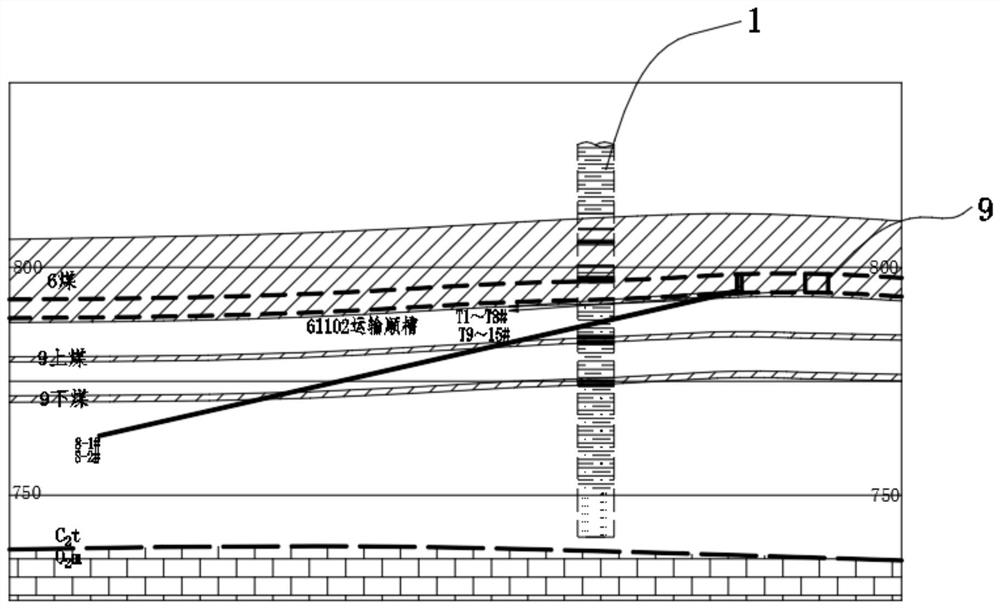

[0042] Such as figure 2 As shown, starting from the working face from top to bottom, they are named as 6 coal floor layer, 9 upper coal floor layer, 9 lower coal floor layer and Austrian ash layer according to the stratum. Between the No. 6 coal floor and the No. 9 upper coal seam, the Austrian ash layer is located about 50m below the No. 6 coal floor.

[0043] Such ...

Embodiment 2

[0046] In this embodiment, on the basis of embodiment 1, the exploration drilling laid out in embodiment 1 is drilled downhole.

[0047] For all exploration drilling holes, use the first drilling tool of Φ168mm to drill to 6m, install the first casing of Φ146mm from 2 to 5.5m, and inject double grout into the gap between the first casing 2 and the side wall of the hole for sealing. After the pressure test is qualified, use the second drilling tool of Φ127mm to drill the hole to 12m, lower the second casing of Φ108mm from 3 to 11m, inject double slurry into the gap between the second casing 3 and the side wall of the hole for sealing, and the second bearing After the pressure test is passed, use the third drilling tool of Φ75mm to drill to the depth of the final hole. The diameter of the final hole is 75mm. Observe the water output, water pressure and water temperature of the final hole, and then inject a sealant into the hole for sealing.

[0048] Such as Figure 8 As shown, ...

Embodiment 3

[0053] The difference between this embodiment and embodiment 2 is:

[0054] (1) if Figure 9 As shown, for all exploration drilling holes, Φ133mm drill bits are used to open holes, and the third casing of Φ146mm is installed for 11m, and the third casing is fixed with sealing agent. After solidification for 4 hours, use The drill bit is sealed to pass 0.5m from the bottom of the pipe, and a high-pressure grouting pump is used to check the quality of the water seal under pressure. The pressure at the orifice reaches 6MPa and stabilizes for 30 minutes, and the orifice and its surroundings do not leak water. until qualified.

[0055] (2) After passing the pressure test, use The drill bit is constructed to the designed final hole position. If the rock wall is found to be loose during the drilling process, and there are abnormal phenomena such as top drilling and large water volume, the drilling must be stopped but the drill pipe must not be pulled out.

[0056] (3) Drilling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com