Sealing mechanism of locking clamping jaw wear-resistant hydraulic pump transmission shaft

A technology of a sealing mechanism and a transmission shaft is applied in the sealing field of hydraulic pumps, which can solve the problems that the hydraulic system of the aircraft cannot work normally, the oil leakage of the hydraulic pump transmission shaft exceeds the standard, and the oil leakage is easy to exceed the standard, so as to avoid the failure of the mechanical seal, The effect of increasing the contact area and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

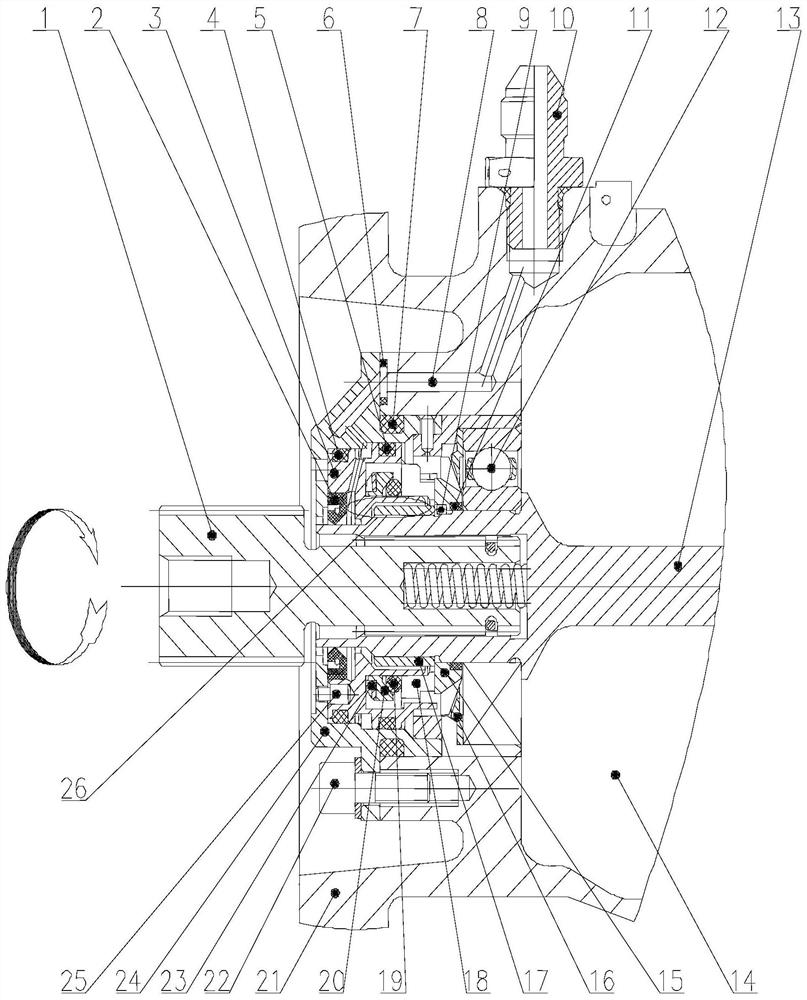

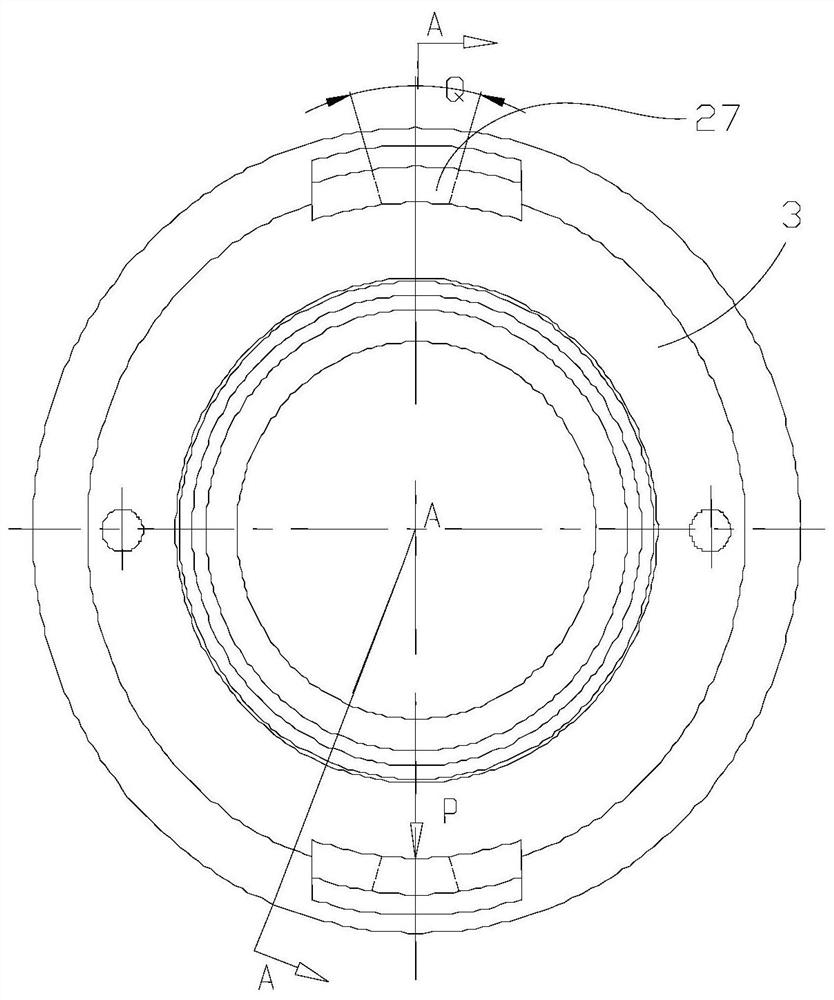

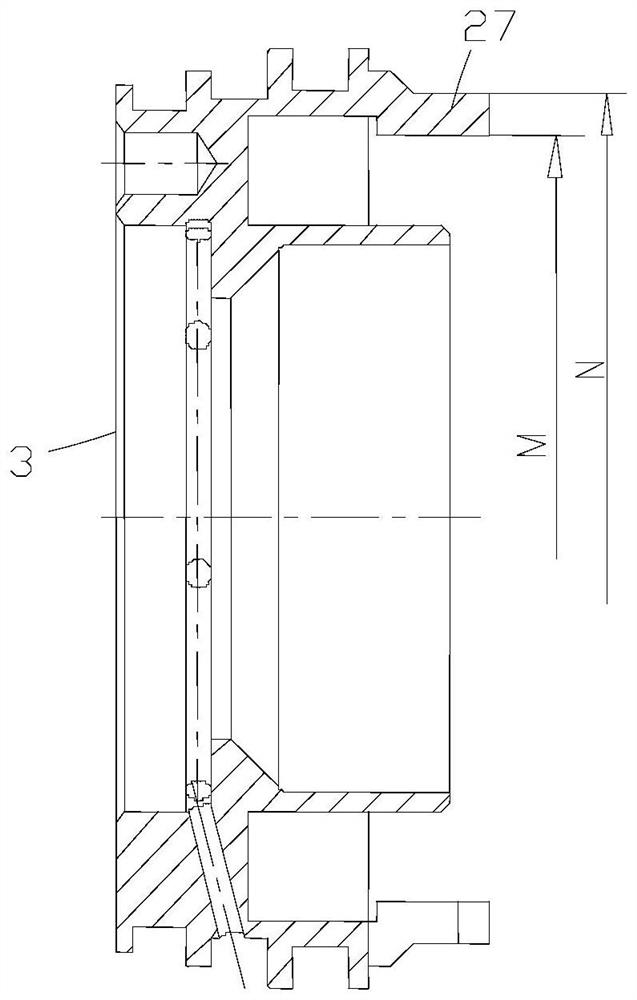

[0032] Example. A sealing mechanism for a drive shaft of a hydraulic pump with a wear-resistant stop claw, such as Figure 1 to Figure 6 As shown, the sealing mechanism of the transmission shaft is composed of the transmission shaft 1, the leather cup 2, the rear cover bushing 3, the sixth sealing ring 4, the first sealing ring 5, the second sealing ring 6, the third sealing ring 7, and the pin 9 , Oil leakage pipe joint 10, fourth sealing ring 11, bearing 12, inner shaft 13, toothed ring 15, retaining ring 16, shaft sleeve 17, sealing bush 18, fifth sealing ring 19, gasket 20, mounting seat 21, bolt 22, wave ring 23, back cover 24, pin 25 and other components. The hydraulic pump is fixed on the aircraft accessory casing through the mounting seat 21, and the inner cavity of the mounting seat is fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com