A device for degrading kitchen waste using black soldier flies

A technology of kitchen waste and black soldier flies, which is applied in the fields of solid waste removal and animal husbandry, can solve the problems of low efficiency, achieve the effects of improving processing efficiency, improving breeding efficiency, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

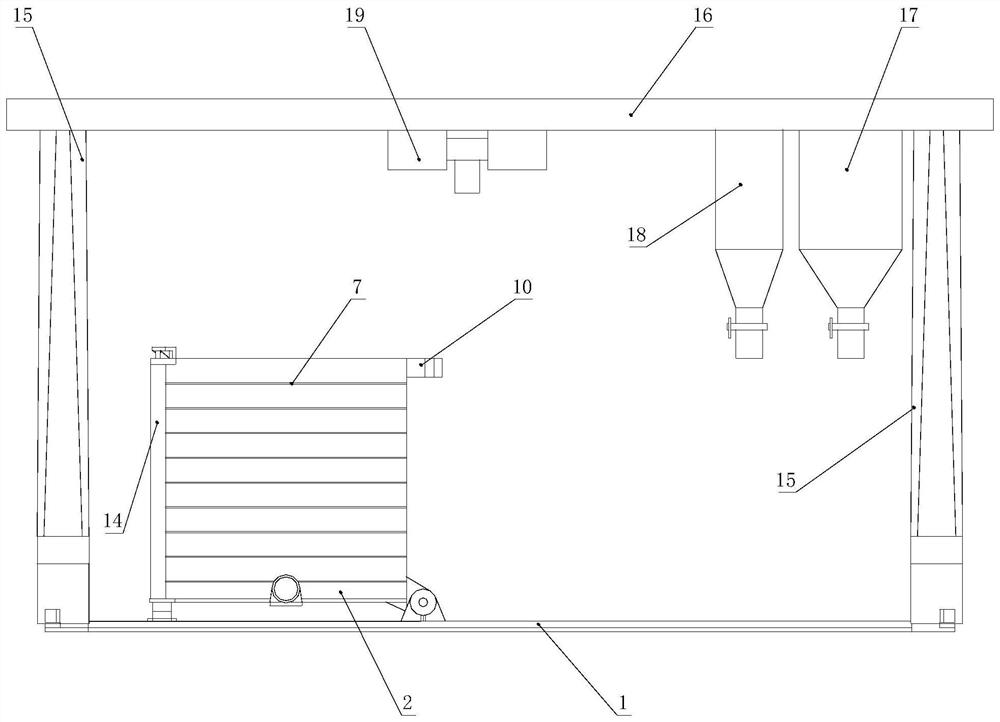

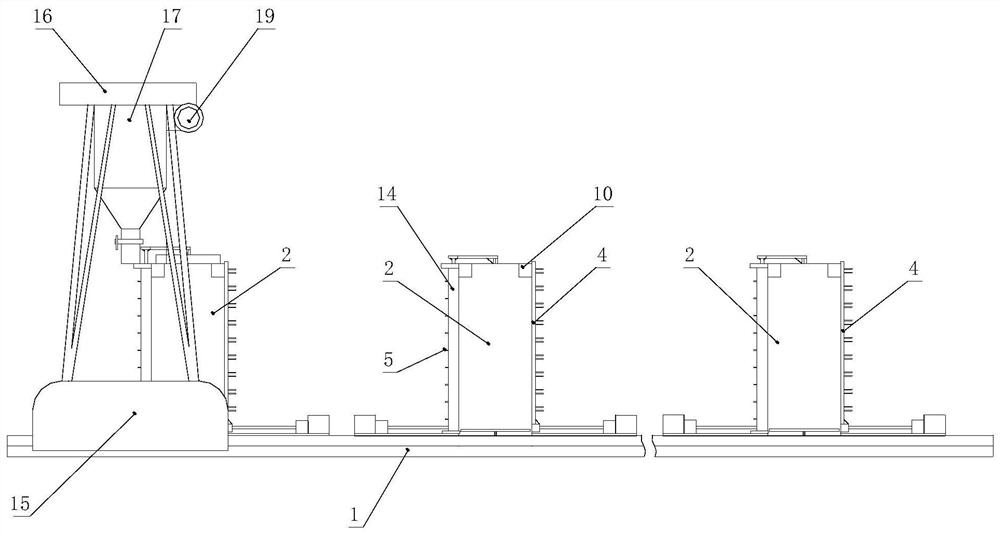

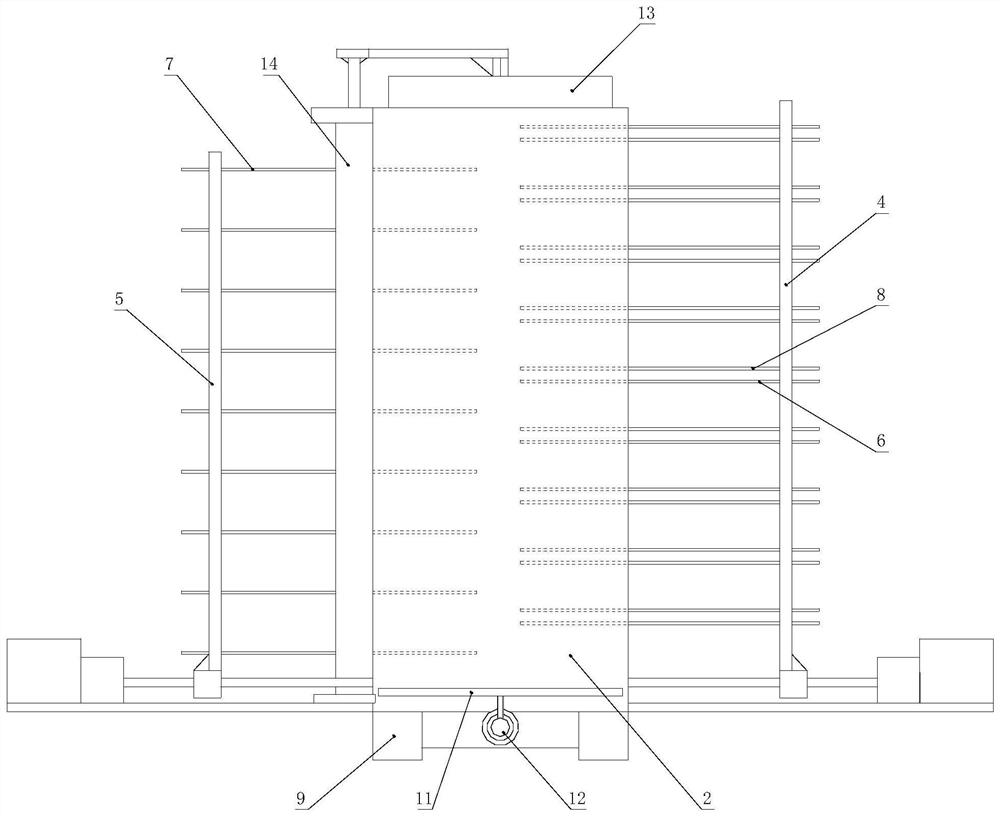

[0033] A device for degrading kitchen waste by using black soldier flies, comprising a support 1 and a breeding bin 2, the lower corner of the right end of the breeding bin 2 is hinged to the bracket 1, and the left end of the breeding bin 2 is provided with a feeding door; the breeding bin 2 There is a ventilation pipe for connecting with the ventilation system inside, and the bottom of the breeding warehouse 2 is provided with a discharge door; The material spacer frame 5, the position of the insect spacer frame 4 and the material spacer frame 5 in the width direction of the breeding warehouse 2 is variable; the insect spacer frame 4 is evenly provided with some first insect barrier plates 6 along the height direction of the culture warehouse 2, The material spacer 5 is evenly provided with some material spacers 7 along the height direction of the breeding warehouse 2; through the relative movement of the insect spacer 4 and the material spacer 5, a number of cloth chambers a...

Embodiment 2

[0044] Based on Embodiment 1, several second insect barriers 8 are also provided on the insect barrier 4, and the space between the second insect barriers 8 and the first insect barriers 6 is used to accommodate black soldier fly larvae, So that there is a large enough gap between the last material partition board 7 and the first insect partition board 6, and then ensure that the black soldier flies are in a suitable growth environment.

[0045] Specifically, the first insect barrier 6, the second insect barrier 8, and the material barrier 7 are all slidably connected to the side walls of the breeding warehouse 2, and the two side walls of the breeding warehouse 2 are equipped with Worm plate 6, the second insect barrier plate 8 and the through hole of material barrier plate 7.

[0046] It can be understood that a sealing rubber strip (such as a polytetrafluoroethylene rubber strip) is fitted in the through holes provided on the two side walls of the breeding warehouse 2 to se...

Embodiment 3

[0048] Based on embodiment 1 or 2, also comprise crane 15, be provided with cloth hopper 17, cloth worm hopper 18 and winch 19 on the beam 16 of described crane 15, described cloth hopper 17, cloth worm hopper 18 and hoist 19 are on beam 16 The position in the length direction is variable (usually realized by a rack and pinion mechanism), and the lower ends of the distribution hopper 17 and the cloth worm hopper 18 are all provided with a distribution switch.

[0049] When in use, move the distributing hopper 17 to the opening of the distributing cavity at the far left or rightmost end of the breeding bin 2 in the overturned state, and turn on the distributing switch at the lower end of the distributing hopper 17 to dispose of kitchen waste. After the distributing cavity is filled, Close the cloth switch at the lower end of the cloth hopper 17, then carry out cloth to the next cloth cavity; then carry out the filling of black soldier fly larvae to the cloth worm cavity in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com