Wide-color-gamut backlight display quantum dot material production device and using method thereof

A quantum dot material and backlight display technology, which is applied in chemical instruments and methods, transportation and packaging, mixing machines, etc., can solve the problem of inability to effectively shorten production time, inability to ensure better production quality, inability to improve efficiency and quality, etc. problem, achieve the effect of saving mixing time, shortening reaction time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

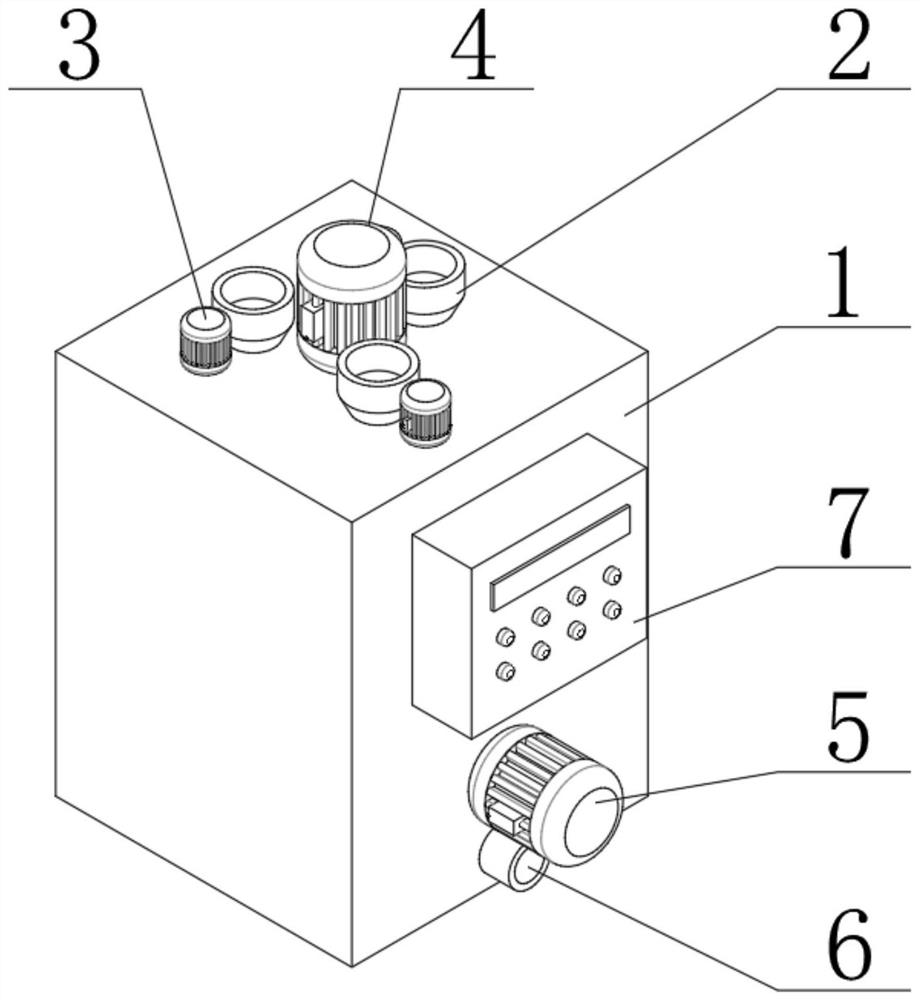

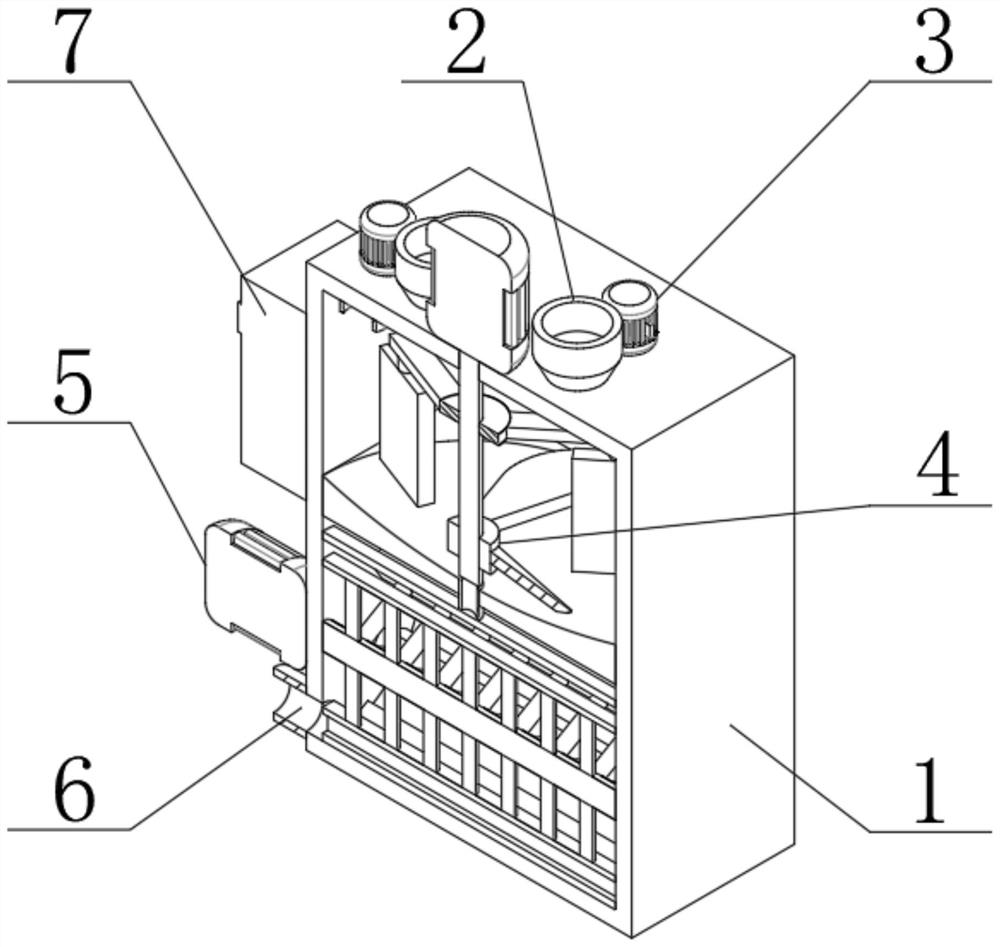

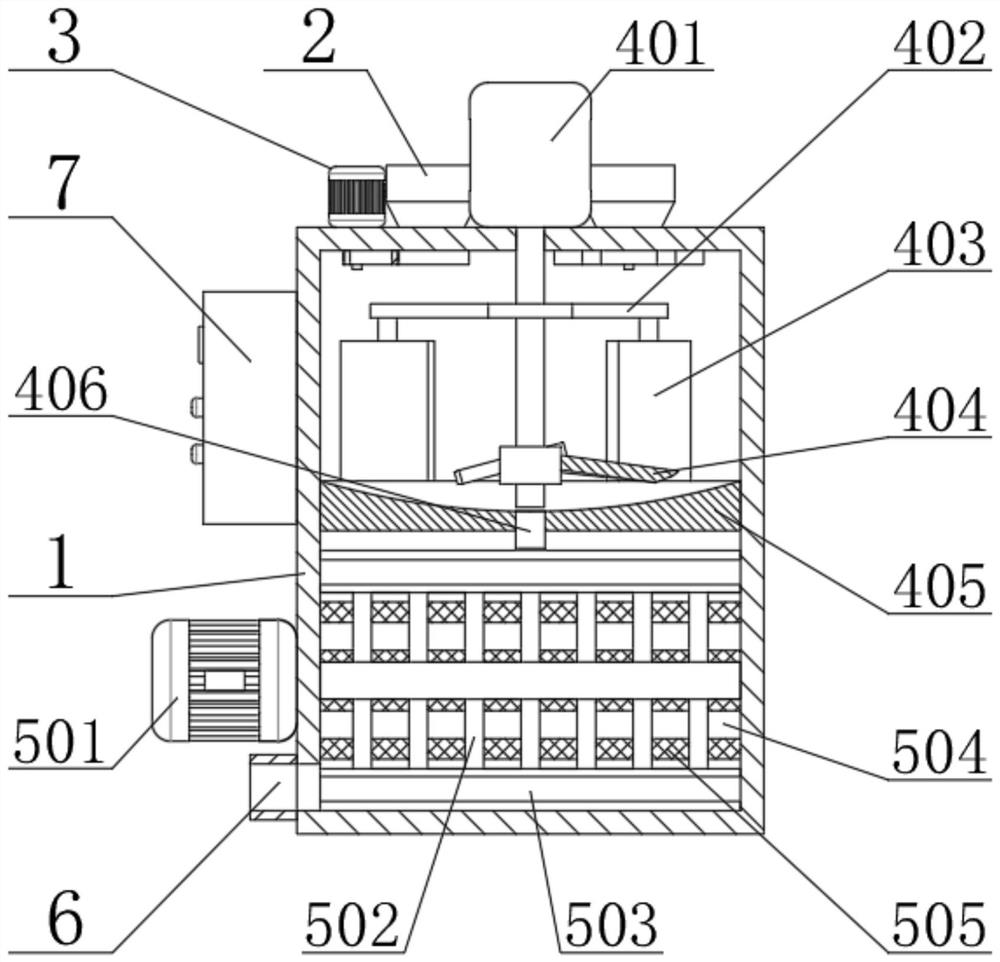

[0028] Example 1: See Figure 1-5 , the present invention provides a technical solution:

[0029] A wide color gamut backlight display quantum dot material production device and its use method, including a box body 1, a feeding hopper 2, a material feeding control device 3, a mixing and stirring device 4, a dissolution reaction device 5 and a liquid outlet pipe 6, the box body The top surface of 1 is evenly connected with the lower hopper 2, and the inner side of the box body 1 is sequentially installed with the feeding control device 3, the mixing and stirring device 4 and the dissolution reaction device 5, and the half part of the right end surface of the box body 1 A control cabinet 7 is fixedly installed, and a liquid outlet pipe 6 is communicated with the bottom of the right end surface of the box body 1 .

[0030] The quantity of the lower hopper 2 is 3, and the lower hopper 2 is evenly distributed on the top surface of the box body 1, and the top surface of the box bod...

Embodiment 2

[0032] Example 2: See Figure 1-5 , the present invention provides a technical solution:

[0033] A wide color gamut backlight display quantum dot material production device and its use method, including a box body 1, a feeding hopper 2, a material feeding control device 3, a mixing and stirring device 4, a dissolution reaction device 5 and a liquid outlet pipe 6, the box body The top surface of 1 is evenly connected with the lower hopper 2, and the inner side of the box body 1 is sequentially installed with the feeding control device 3, the mixing and stirring device 4 and the dissolution reaction device 5, and the half part of the right end surface of the box body 1 A control cabinet 7 is fixedly installed, and a liquid outlet pipe 6 is communicated with the bottom of the right end surface of the box body 1 .

[0034] The quantity of the lower hopper 2 is 3, and the lower hopper 2 is evenly distributed on the top surface of the box body 1, and the top surface of the box bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com