Production and processing device for concrete blocks

A concrete block and processing device technology, applied in the direction of clay preparation device, supply device, unloading device, etc., can solve the problems of affecting the quality of blocks produced, insufficient mixing, and insufficient firmness, so as to improve production quality and speed up work Efficiency, the effect of ensuring the degree of concrete mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

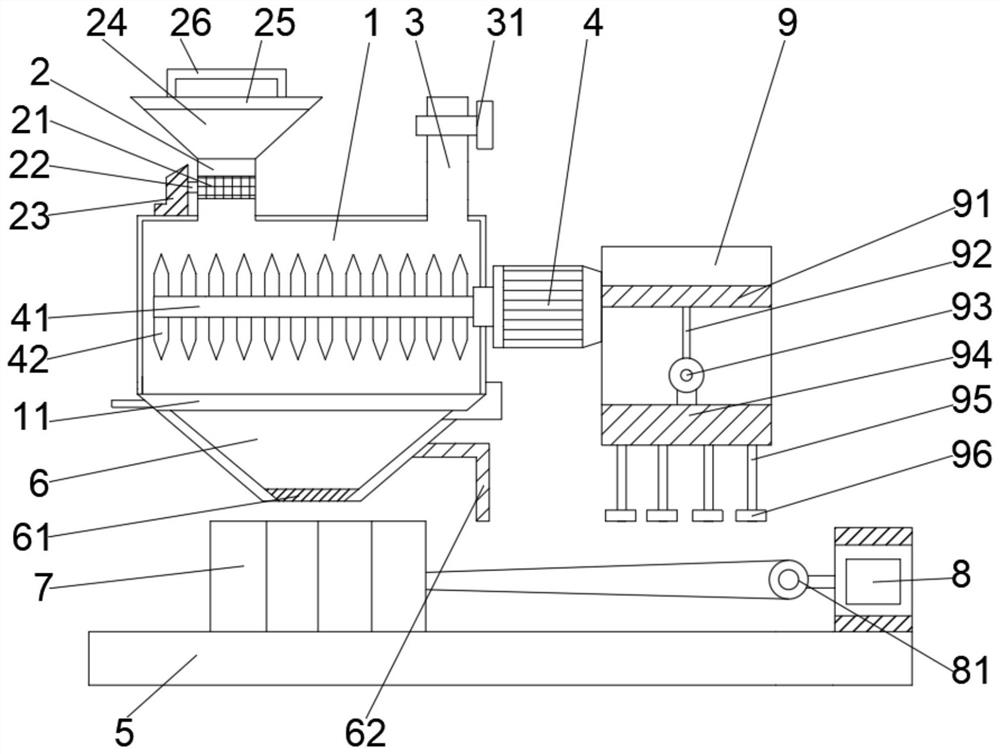

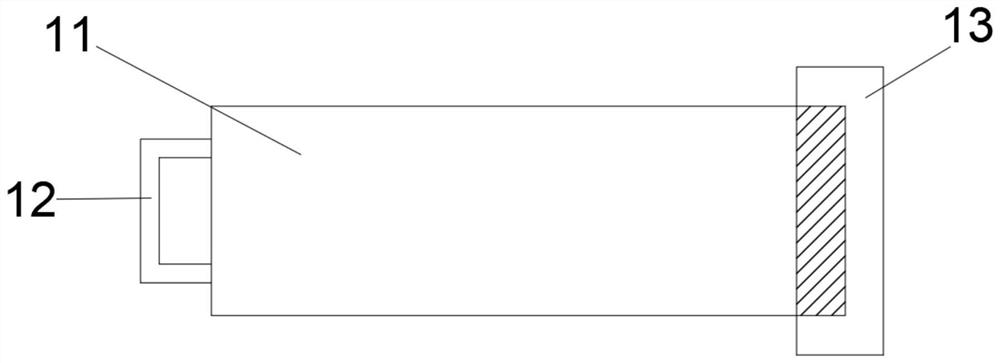

[0022] As a preferred embodiment of the present invention, a push-pull switch 12 is fixedly connected to the left side of the push plate 11, and a snap plate 13 is provided on the right side of the push plate 11, which has a simple and reasonable structure and is easy to control.

[0023] As a preferred embodiment of the present invention, a filter plate 21 is provided in the middle of the feed pipe 2, a vibration rod 22 is connected to the left side of the filter plate 21, and a vibration machine 23 is installed at the left end of the vibration rod 22 to remove impurities , Improve production quality.

[0024] As a preferred embodiment of the present invention, the upper end of the feed pipe 2 is provided with a funnel-type feed port 24, and the upper side of the funnel-type feed port 24 is provided with a feed port cover 25, and the feed port A cover switch 26 is connected to the upper side of the cover 25 to facilitate filling and improve work efficiency.

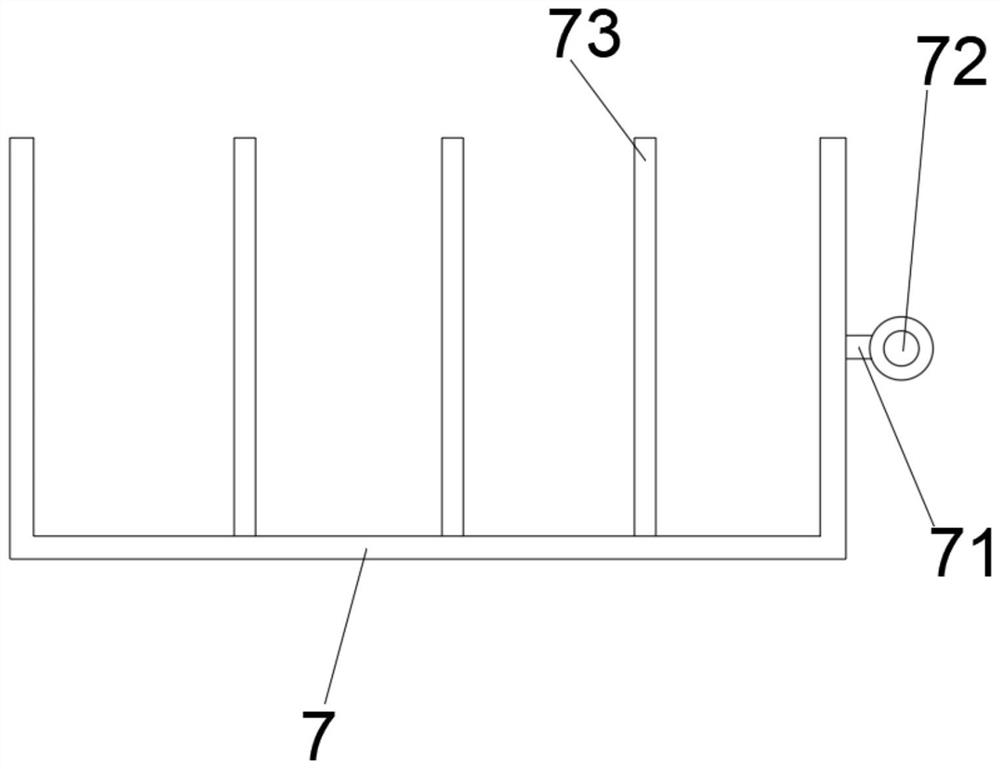

[0025] As a preferred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com