High-strength organic glass for internal induction scratch repair

A plexiglass, high-strength technology, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the effects of high water absorption, weather resistance, acid and alkali resistance, dimensional stability, and insulation , easy to produce silver streaks and other problems, to achieve the effect of improving tensile resistance and wear resistance, improving repair efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

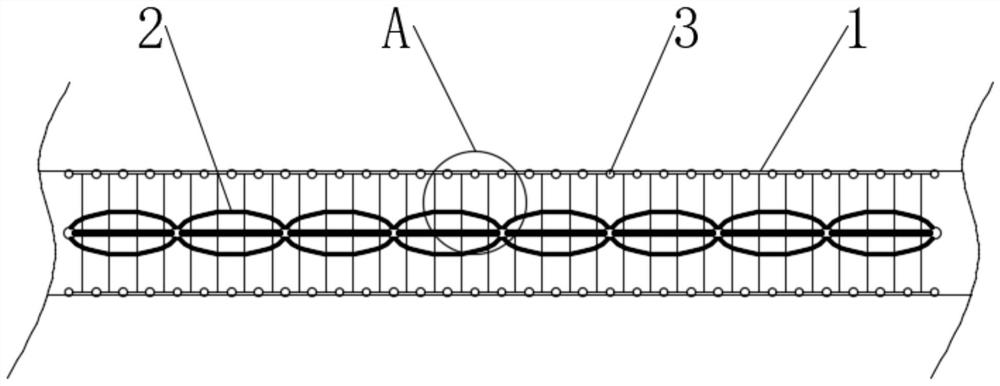

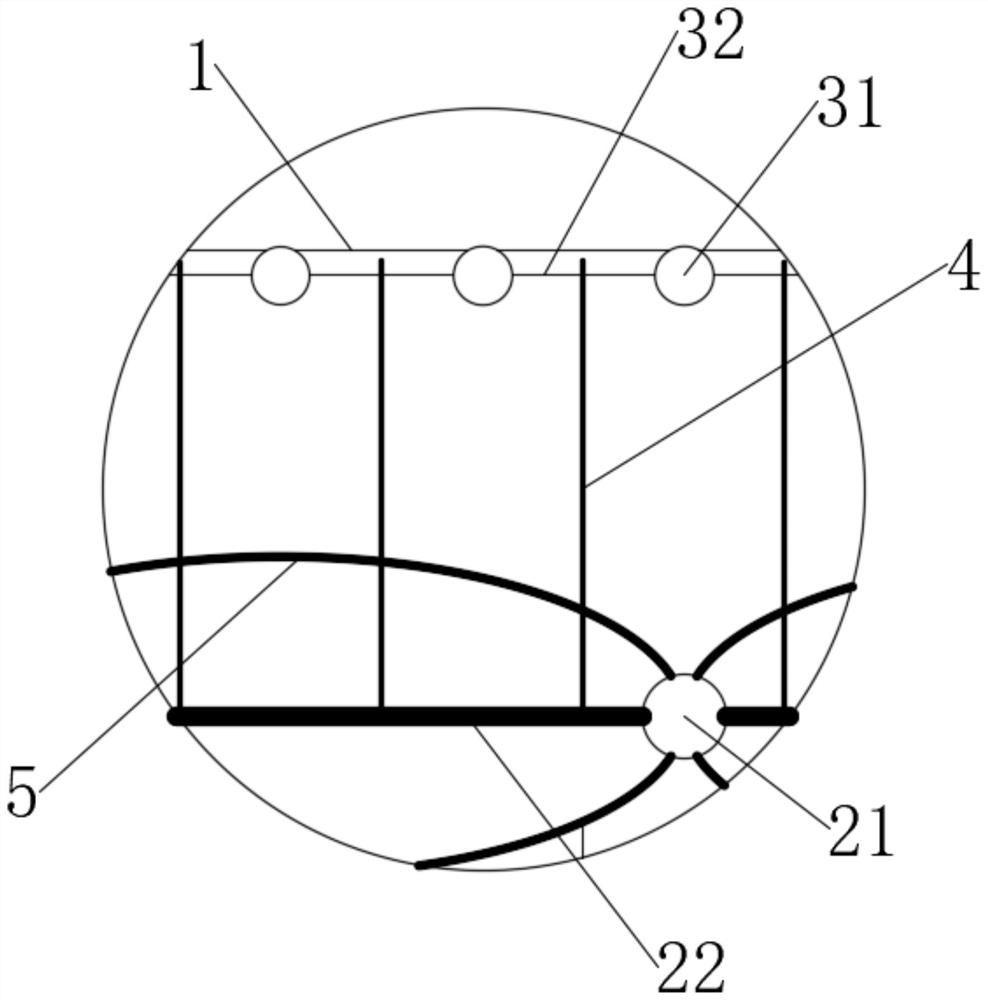

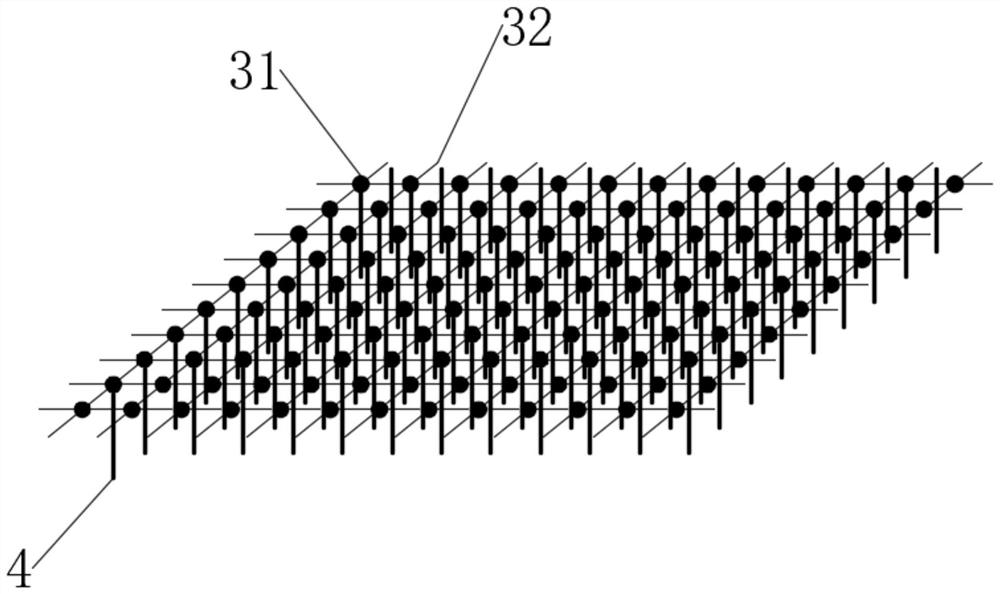

[0044] see Figure 1-3 , a high-strength plexiglass for internal induction scratch repair, comprising a plexiglass body 1, the plexiglass body 1 is inlaid with an internal tightening repair mesh 2, and the upper and lower surfaces of the plexiglass body 1 are inlaid and connected with a scratch-resistant wear-resistant mesh 3. The internal tightening repair net 2 includes a plurality of evenly distributed fixed-point glass balls 21 and retractable elastic rods 22 connected to the fixed-point glass balls 21. Sectional repair tension rod 5, the damage guide wear-resistant mesh 3 includes a plurality of uniformly distributed wear-resistant silicon carbide balls 31 and glass fiber wires 32 connected to the wear-resistant silicon carbide balls 31, between adjacent wear-resistant silicon carbide balls 31 There are vertically distributed internal sensing connecting rods 4, and one end of the internal sensing connecting rod 4 away from the damage-guiding wear-resistant mesh 3 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com