Liquid self-repairing hydrophobic glass based on negative pressure technology

A hydrophobic glass, self-healing technology, applied in glass/slag layered products, chemical instruments and methods, layered products, etc., can solve problems affecting driving safety, etc., to improve glass light transmittance, reduce wiping, reduce The effect of secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

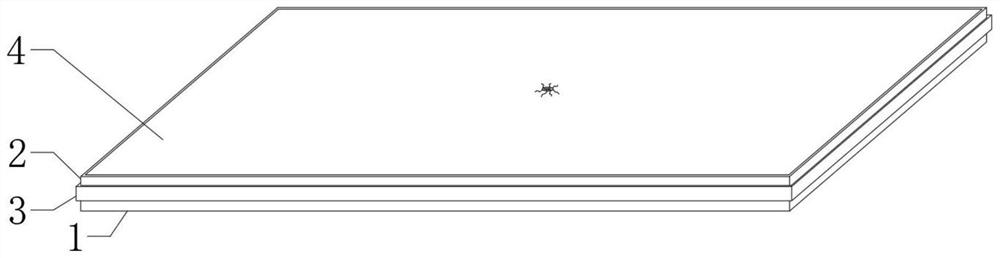

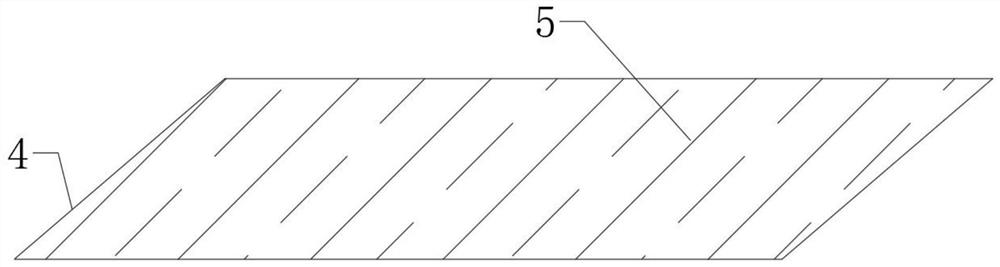

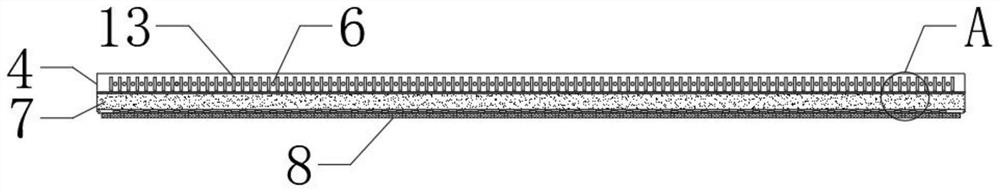

[0043] See Figure 1-6 , A liquid self-repairing hydrophobic glass based on negative pressure technology, including a glass inner layer 1, a glass outer layer 2 is provided on the upper side of the glass inner layer 1, and a repair film 4 is provided on the upper end of the glass outer layer 2, and the glass inner layer A connecting frame 14 is fixedly connected between 1 and the glass outer layer 2. The inner wall of the connecting frame 14 is drilled with a diffuser hole. The diffuser hole is provided with diammine cuprous ions 12, and the outer ends of the glass inner layer 1 and the glass outer layer 2 The water-swellable adhesive strip 3 is fixedly connected, and the inside of the repair film 4 is filled with silver bromide 13 and copper oxide microcrystal grains 6, and the silver bromide 13 and copper oxide microcrystal grains 6 are evenly distributed inside the repair film 4 When the vehicle is driving, and the driving direction is opposite to the sunlight, the copper oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com