Insulation board prepared from ardealite-based hydraulic composite cementing material and preparation method thereof

A technology of composite cementitious materials and phosphogypsum, which is applied in the field of building materials, can solve the problems of weak thermal insulation performance improvement, etc., and achieve the effects of good setting and hardening effects, excellent mechanical properties and durability, and variable decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

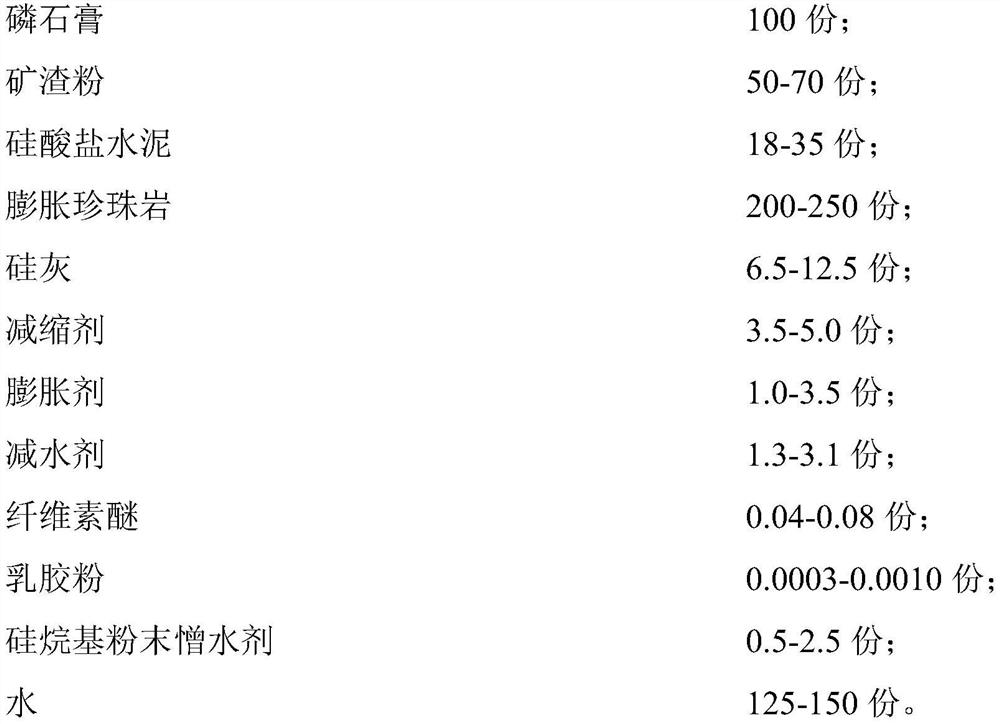

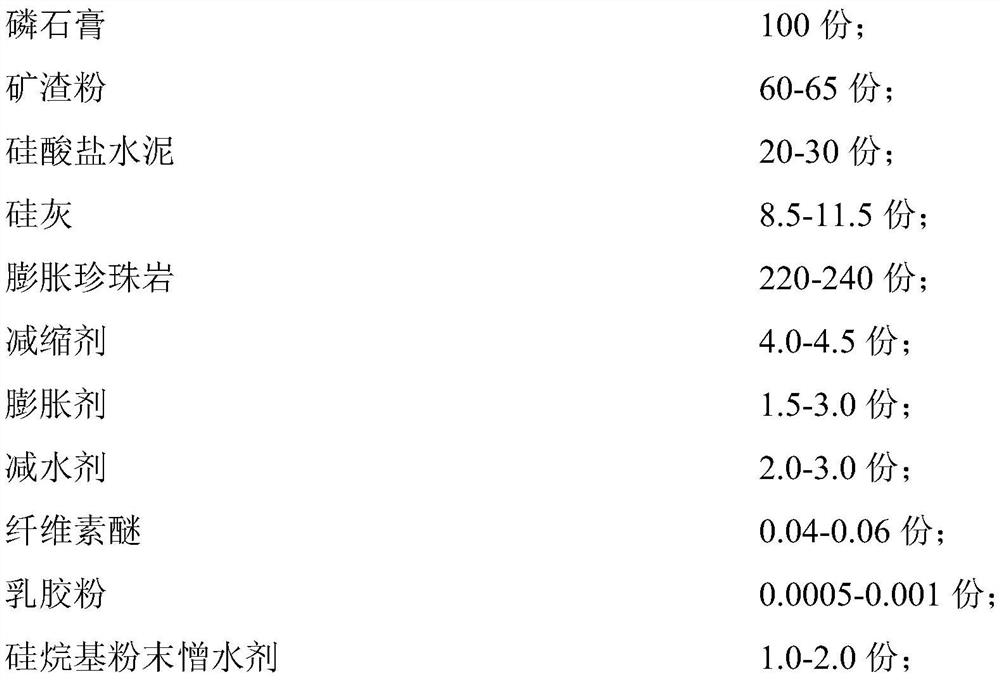

[0040] A thermal insulation board prepared from phosphogypsum-based hydraulic composite cementitious material, the distribution ratio of each component is:

[0041] 100 parts of phosphogypsum, 50 parts of slag powder, 18 parts of Portland cement, 12.5 parts of silica fume, 200 parts of expanded perlite, 3.5 parts of shrinkage reducing agent, 1.0 part of expansion agent, 1.3 parts of water reducing agent, 0.05 part of cellulose ether, 0.0010 parts of latex powder, 0.5 parts of silane-based powder water repellent and 125 parts of water.

[0042] 100 parts of phosphogypsum, 50 parts of slag powder, 18 parts of Portland cement, 12.5 parts of silica fume, 200 parts of expanded perlite; 3.5 parts of shrinkage reducing agent, 1.0 part of expansion agent, 1.3 parts of water reducing agent, and 0.05 parts of cellulose ether , 0.0010 parts of latex powder, 0.5 parts of silane-based powder water repellent and 125 parts of water were weighed, and mixed and stirred according to the batch a...

Embodiment 2

[0044] A thermal insulation board prepared from phosphogypsum-based hydraulic composite cementitious material, the distribution ratio of each component is:

[0045]100 parts of phosphogypsum, 70 parts of slag powder, 35 parts of Portland cement, 11.5 parts of silica fume, 250 parts of expanded perlite, 5.0 parts of shrinkage reducing agent, 3.5 parts of expansion agent, 3.0 parts of water reducing agent, 0.08 parts of cellulose ether, 0.001 part of latex powder, 2.5 parts of silane-based powder water repellent and 150 parts of water.

[0046] According to the mass ratio of 100 parts of phosphogypsum, 70 parts of slag powder, 35 parts of Portland cement, 11.5 parts of silica fume, and 250 parts of expanded perlite; 0.08 parts of ether, 0.001 parts of latex powder, 2.5 parts of silane-based powder water repellent and 150 parts of water were weighed, mixed and stirred evenly to obtain the desired product. The performance test results are shown in Table 1.

Embodiment 3

[0048] A thermal insulation board prepared from phosphogypsum-based hydraulic composite cementitious material, the distribution ratio of each component is:

[0049] 100 parts of phosphogypsum, 63 parts of slag powder, 25 parts of Portland cement, 10 parts of silica fume, 230 parts of expanded perlite, 4.3 parts of shrinkage reducing agent, 2.3 parts of expansion agent, 2.5 parts of water reducing agent, 0.05 part of cellulose ether, 0.0008 parts of latex powder, 1.5 parts of silane-based powder water repellent and 135 parts of water.

[0050] According to the mass ratio of 100 parts of phosphogypsum, 63 parts of slag powder, 25 parts of Portland cement, 10 parts of silica fume, and 230 parts of expanded perlite; 4.3 parts of shrinkage reducing agent, 2.3 parts of expansion agent, 2.5 parts of water reducing agent, cellulose 0.05 parts of ether, 0.0008 parts of latex powder, 1.5 parts of silane-based powder water repellent and 135 parts of water were weighed, mixed and stirred ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com