Imprinted thin film material for selectively separating drug-resistant bacillus as well as preparation and application thereof

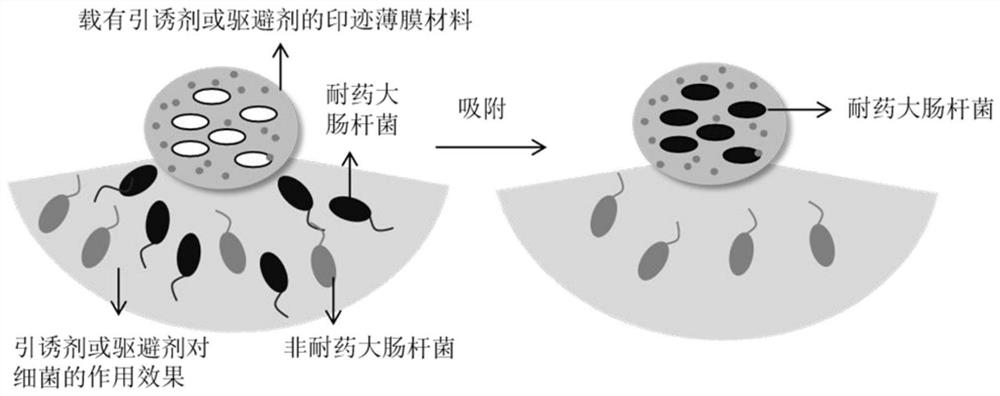

An imprinted membrane and selective technology, which is applied in the direction of isolation of microorganisms, microorganism-based methods, biochemical equipment and methods, etc., can solve the problem of insufficient selectivity in the isolation of drug-resistant bacteria, the inability to effectively finely separate drug-resistant bacteria, and the elution of template bacteria To achieve the effect of promoting selective movement and active identification, effective and fine isolation of drug-resistant bacteria, and high selective isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

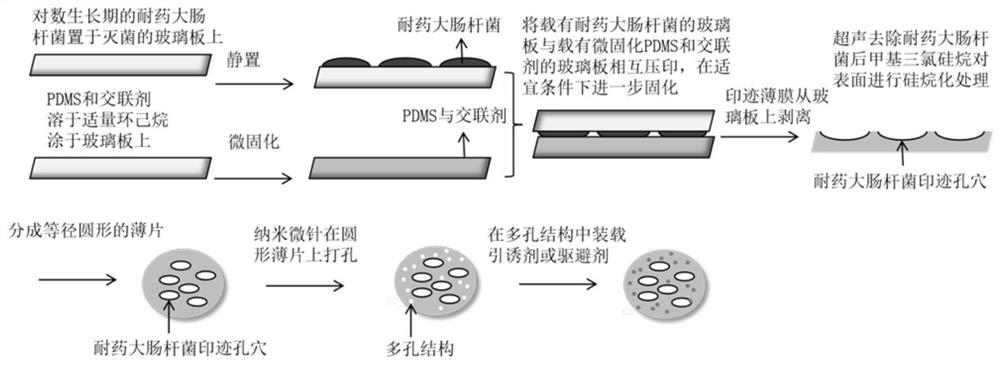

[0040] A method for preparing an imprinted film material for selectively isolating drug-resistant Escherichia coli of the present invention comprises the following steps:

[0041] Step 1: Dissolve polydimethylsiloxane (PDMS) and cross-linking agent in an appropriate amount of cyclohexane, apply the solution on a glass plate, and place it at 60-90°C for micro-curing for 3-5 minutes, wherein, The volume ratio of polydimethylsiloxane (PDMS) to the crosslinking agent is 1:0.08-0.15, and the volume of cyclohexane is 1-2 mL. At the same time, take an appropriate amount of drug-resistant Escherichia coli in the logarithmic growth phase and dilute to an appropriate concentration (OD 600 =0.06~0.08), and take 1~3mL of bacterial suspension dropwise onto a sterilized glass plate, let it stand at 3~6°C for 2~4 hours to allow the bacteria to settle, and then remove excess solvent in a sterile ventilated environment . Then the glass plate loaded with the template bacteria was pressed into...

Embodiment 1

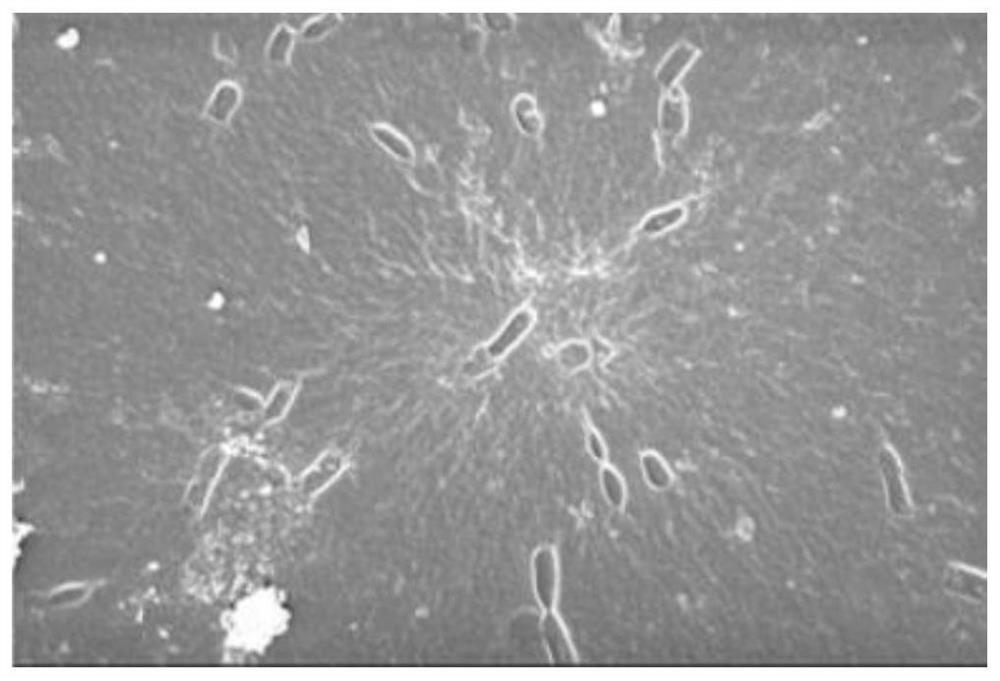

[0047] Dissolve 2mL of polydimethylsiloxane (PDMS) and 0.2mL of cross-linking agent in 1mL of cyclohexane, and apply all of them evenly on a glass plate, and slightly cure at 80°C for 4min before use. At the same time, take an appropriate amount of drug-resistant Escherichia coli in the logarithmic growth phase, wash with PBS buffer solution with pH 7.4, and dilute to OD 600 = 0.07. Take 2 mL of the above bacterial suspension and drop it on a sterilized glass plate, let it stand at 4 °C for 2 h to allow the bacteria to settle, and then remove excess solvent in a sterile ventilated environment. A sterile glass plate coated with bacteria was pressed into the micro-cured PDMS surface, kept at 37.5 °C for 7 h, and further cured at 80 °C for 1 h. The imprinted film was peeled off from the glass plate, and then the template bacteria were washed and removed with deionized water under ultrasonic conditions. Place the imprinted film together with 10 mL of 0.1% methyltrichlorosilane s...

Embodiment 2

[0050] Dissolve 2mL of polydimethylsiloxane (PDMS) and 0.16mL of cross-linking agent in 2mL of cyclohexane, and apply all of them evenly on a glass plate, and slightly cure at 90°C for 3min before use. At the same time, take an appropriate amount of drug-resistant Escherichia coli in the logarithmic growth phase, wash with PBS buffer solution with pH 7.4, and dilute to OD 600 = 0.08. Take 1 mL of the above bacterial suspension and drop it on a sterilized glass plate, let it stand at 3°C for 3 h to allow the bacteria to settle, and then remove excess solvent in a sterile ventilated environment. A sterile glass plate coated with bacteria was pressed into the above micro-cured PDMS surface, kept at 37.5 °C for 6 h, and further cured at 70 °C for 2 h. The imprinted film was peeled off from the glass plate, and then the template bacteria were washed and removed with deionized water under ultrasonic conditions. Place the imprinted film together with 5 mL of 0.15% methyltrichloro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com