A kind of high-fixation disperse black dye composition and its preparation method and use method

A dye composition and disperse black technology, which is applied in the field of printing and dyeing, can solve the problems of limited improvement of dyeing rate and color fastness, too long processing time, and limited dyes, so as to improve color fixing rate and color Fastness, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

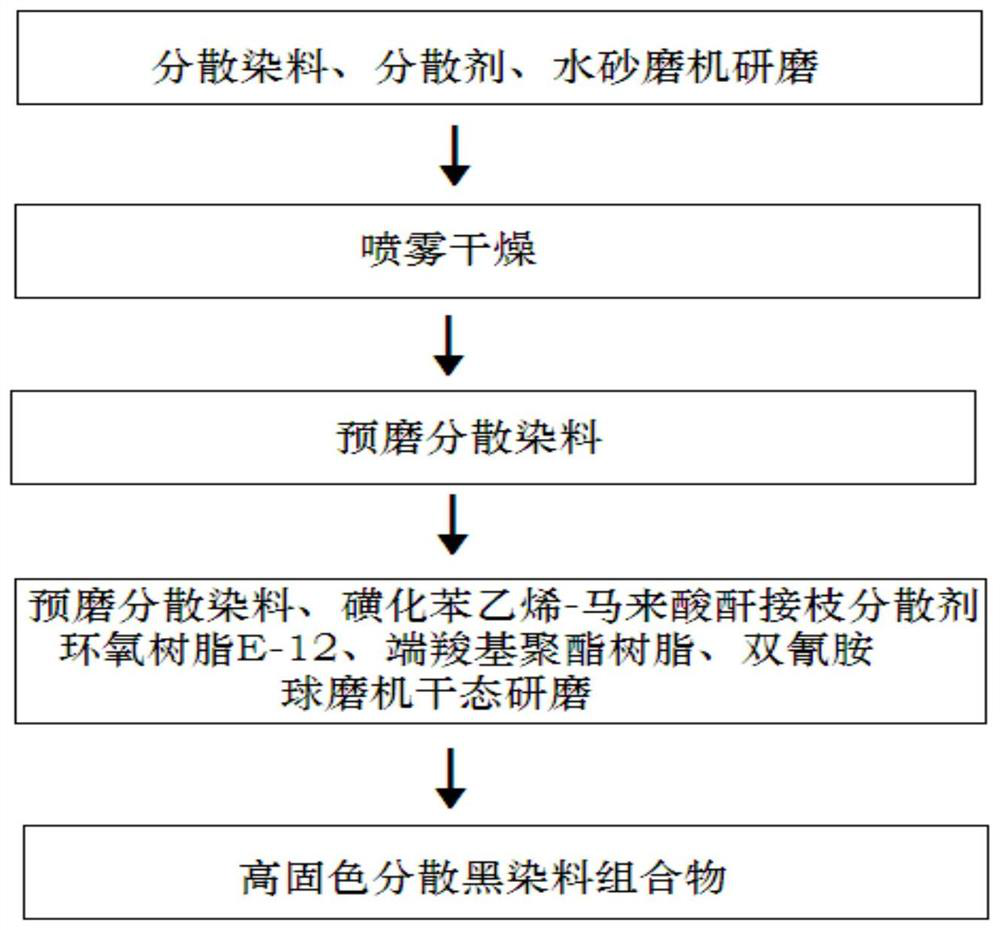

Method used

Image

Examples

Embodiment 1

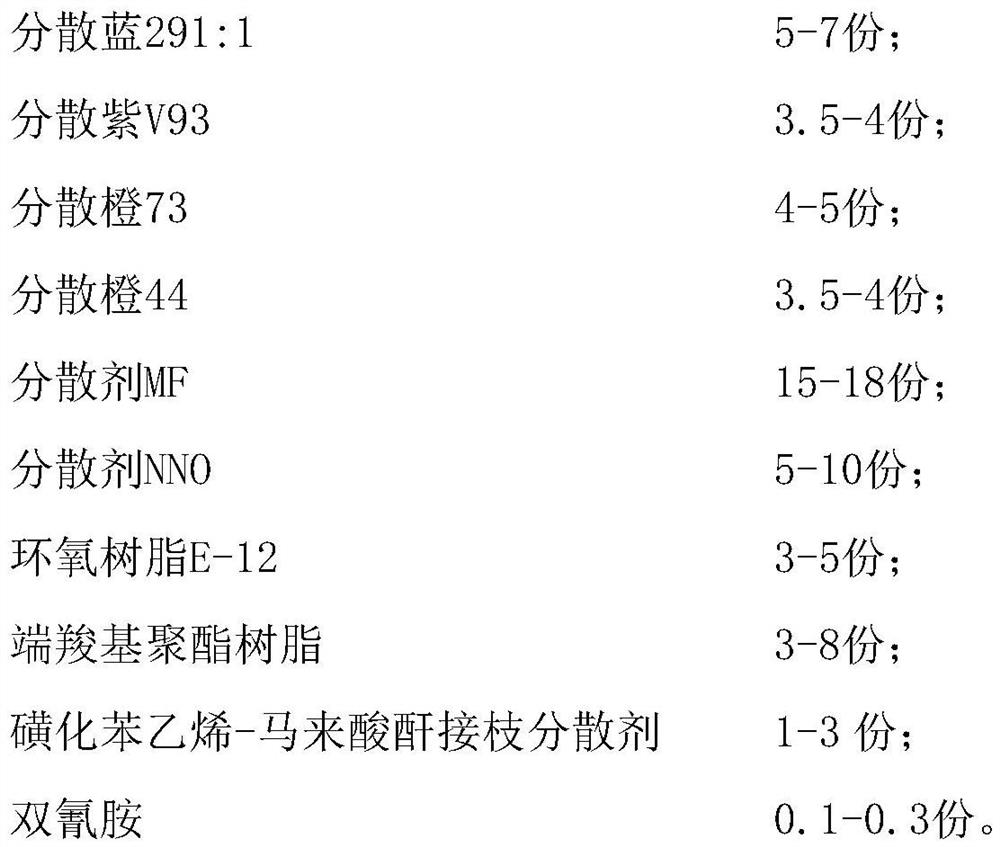

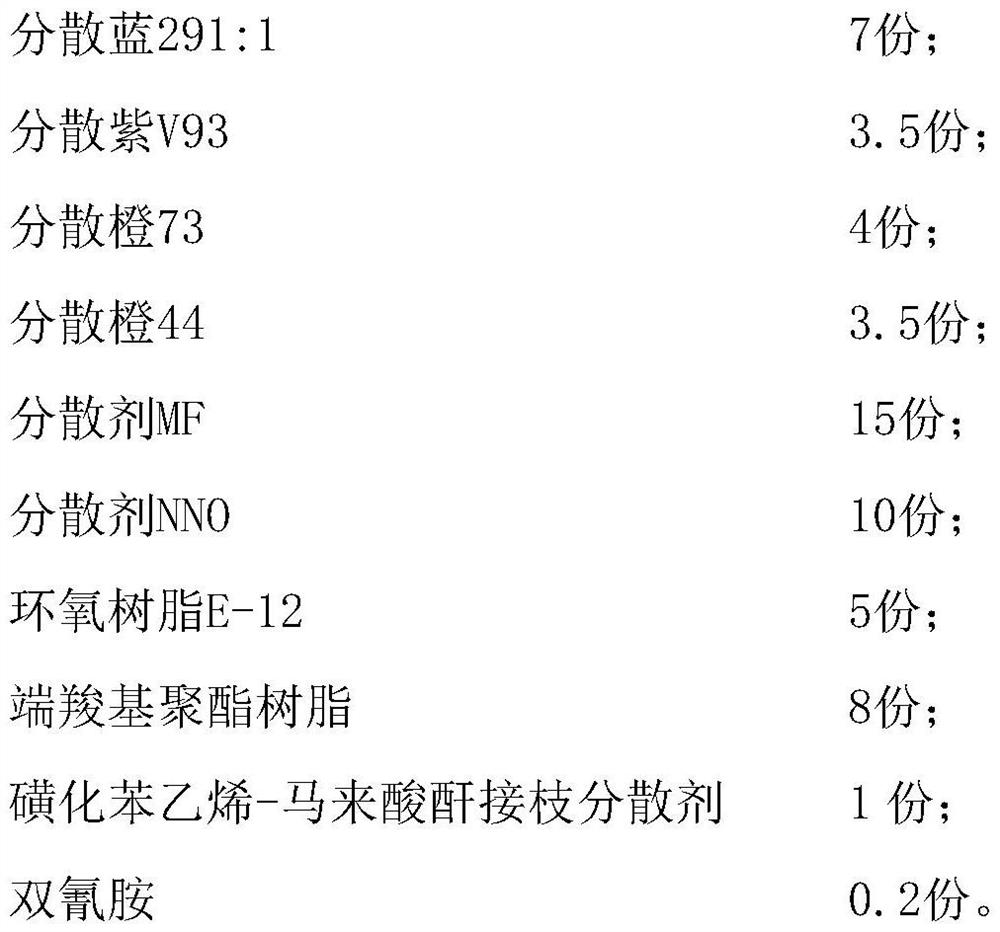

[0032] A high-fixation disperse black dye composition, comprising the following component raw materials in parts by weight:

[0033]

[0034] With the raw material proportioning of above-mentioned parts by weight, the method for specifically preparing the high-fixation disperse black dye composition is as follows:

[0035] (1) Add disperse blue 291:1, disperse violet V93, disperse orange 73, disperse orange 44, dispersant MF, dispersant NNO to deionized water to make a slurry, the amount of deionized water added is disperse blue 291:1 , Disperse Violet V93, Disperse Orange 73, Disperse Orange 44, Disperse Agent MF, Disperse Agent NNO 8 times the total mass; then send it into a sand mill for grinding, and the sand mill selects zirconia with a diameter of 0.05mm as the grinding medium, and the sand The running speed of the mill is 1.5m / s; the grinding time is controlled at 3h, the grinding medium is removed by filtration, and then spray-dried at 110°C by a spray dryer to obta...

Embodiment 2

[0041] A high-fixation disperse black dye composition, comprising the following component raw materials in parts by weight:

[0042]

[0043] With the raw material proportioning of above-mentioned parts by weight, the method for specifically preparing the high-fixation disperse black dye composition is as follows:

[0044] (1) Add disperse blue 291:1, disperse violet V93, disperse orange 73, disperse orange 44, dispersant MF, dispersant NNO to deionized water to make a slurry, the amount of deionized water added is disperse blue 291:1 , Disperse Violet V93, Disperse Orange 73, Disperse Orange 44, Disperse Agent MF, Disperse Agent NNO 5 times the total mass; then send it into a sand mill for grinding, and the sand mill selects zirconia with a diameter of 0.05mm as the grinding medium, sand The running speed of the mill is 1m / s; the grinding time is controlled at 3h, the grinding medium is removed by filtration, and then spray-dried at 110°C by a spray dryer to obtain a pre-g...

Embodiment 3

[0050] A high-fixation disperse black dye composition, comprising the following component raw materials in parts by weight:

[0051]

[0052] With the raw material proportioning of above-mentioned parts by weight, the method for specifically preparing the high-fixation disperse black dye composition is as follows:

[0053] (1) Add disperse blue 291:1, disperse violet V93, disperse orange 73, disperse orange 44, dispersant MF, dispersant NNO to deionized water to make a slurry, the amount of deionized water added is disperse blue 291:1 , Disperse Violet V93, Disperse Orange 73, Disperse Orange 44, dispersant MF, and dispersant NNO are 10 times the total mass; then they are sent to a sand mill for grinding, and the sand mill uses zirconia with a diameter of 0.05mm as the grinding medium, and the sand The running speed of the mill is 1.5m / s; the grinding time is controlled at 3h, the grinding medium is removed by filtration, and then spray-dried at 110°C by a spray dryer to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com