Construction method of concrete roof water leakage repairing system

A construction method and water leakage technology, applied in the direction of roof, roof drainage, roof covering, etc., can solve the problems of roof thermal insulation performance decline, high cost, long construction period, etc., to achieve improved thermal insulation performance and low cost , the effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

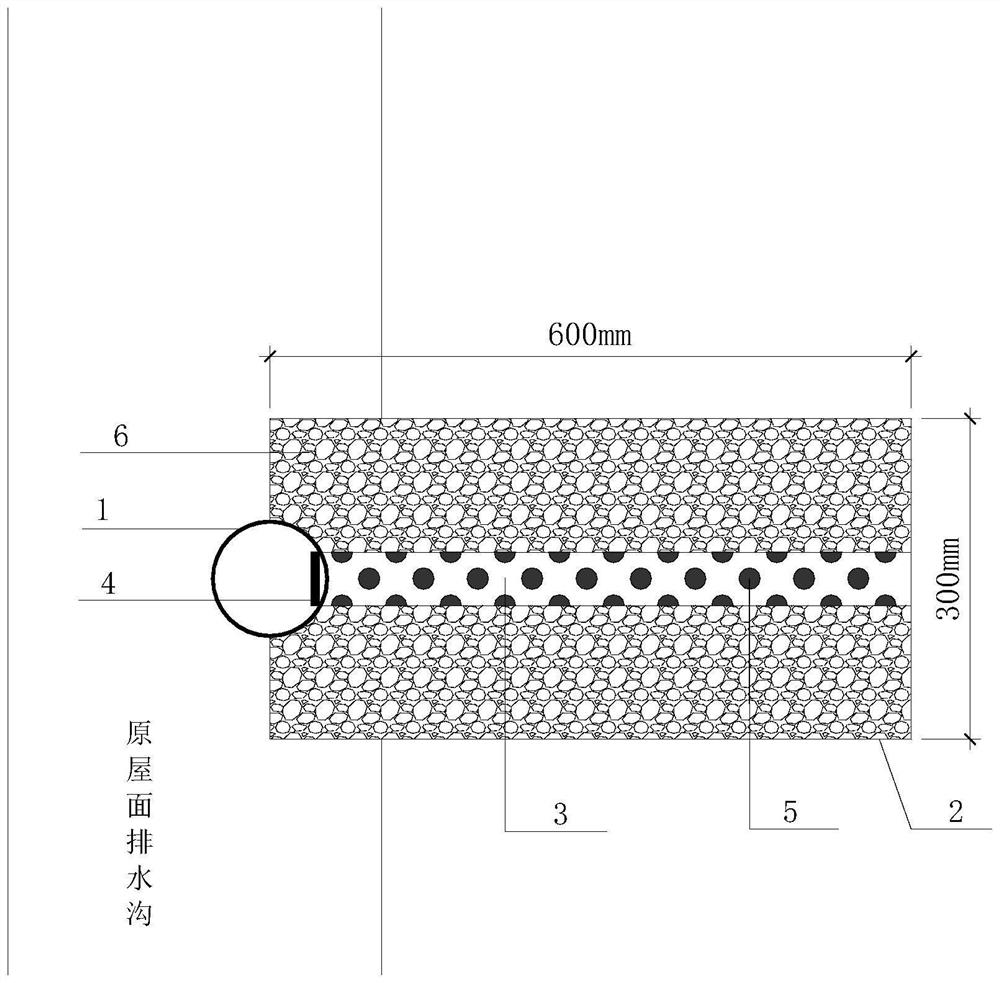

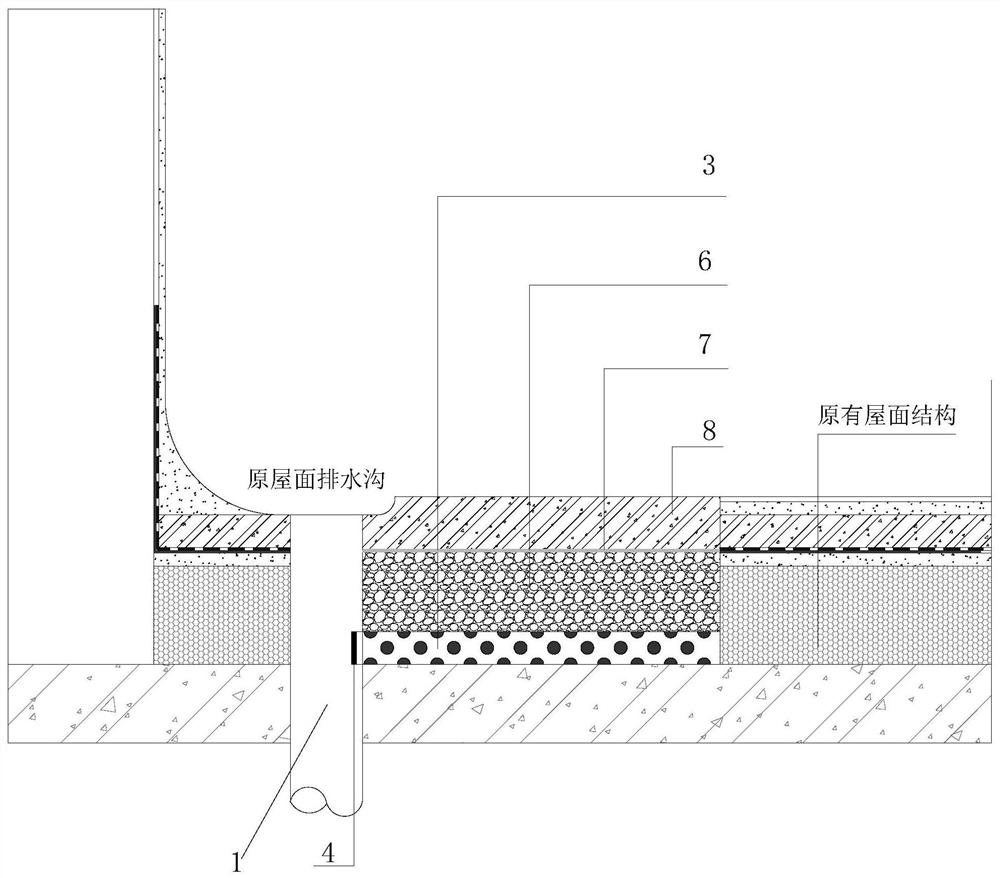

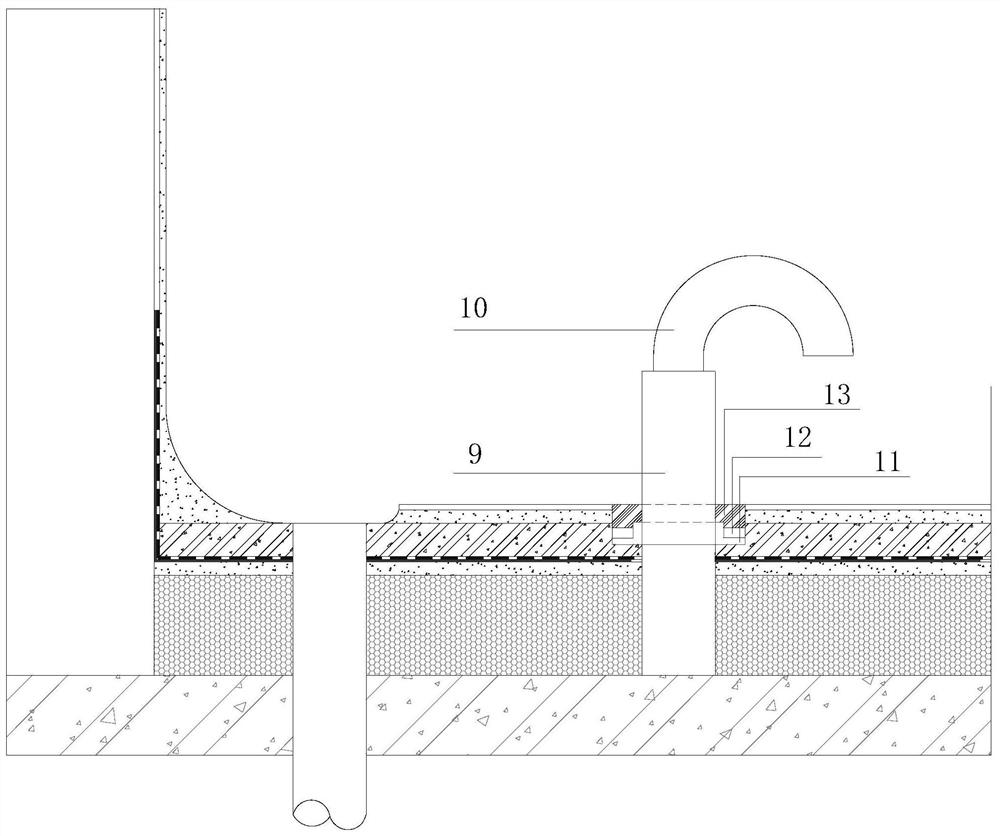

[0068] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0069] The main causes of water leakage on traditional roofs are as follows: ①Due to the uneven settlement of the foundation, the construction joints of the parapet and the roof slab are cracked and separated; ②When the concrete is poured, the vibration is not dense, resulting in honeycomb in the concrete; ③Insulation Cushion breaks on the first floor caused water channeling; ④ Waterproof treatment was not strengthened at the edge of the inner corner pipe; ⑤ Waterproof design and construction were not in place or waterproof materials did not meet the standards.

[0070] According to the analysis of the reasons for the above leakage, this waterproof plugging scheme adopts the overall renovation method, uses high-elastic waterproof sealant materials, adopts a combination of various materials and various processes, and determines the corresponding waterproof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap