Dry-process cement firing system

A technology of dry process cement and cement rotary kiln, which is applied in the direction of furnace type, preheating cost, furnace, etc., and can solve problems such as increasing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

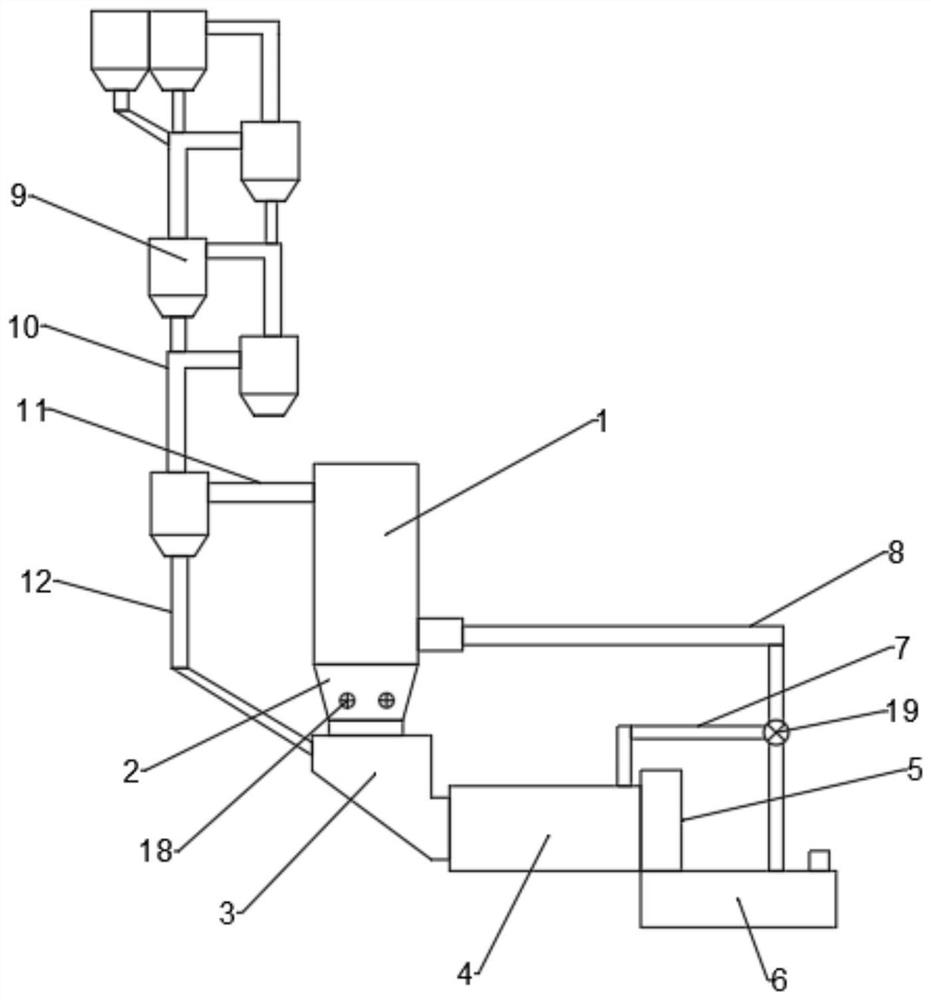

[0027] Example: such as Figure 1 to Figure 2 As shown, the dry cement firing system according to the embodiment of the present invention includes a calciner main body 1, a reduction chamber 2 is provided at the lower end of the calciner main body 1, and a kiln tail smoke chamber 3 is provided at the lower end of the reduction chamber 2 , one end of the kiln tail smoke chamber 3 is provided with a cement rotary kiln 4, the end of the cement rotary kiln 4 away from the kiln tail smoke chamber 3 is provided with a fuel addition chamber 5, and the lower end of the fuel addition chamber 5 is provided with A cooler 6, a secondary air duct 7 is connected between the cooler 6 and the cement rotary kiln 4, a tertiary air duct 8 is connected between the cooler 6 and the calciner main body 1, and the decomposition The upper side of the furnace body 1 is provided with connected five-stage preheaters 9, and the five-stage preheaters 9 are connected through five-stage cyclones 10;

[0028...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com