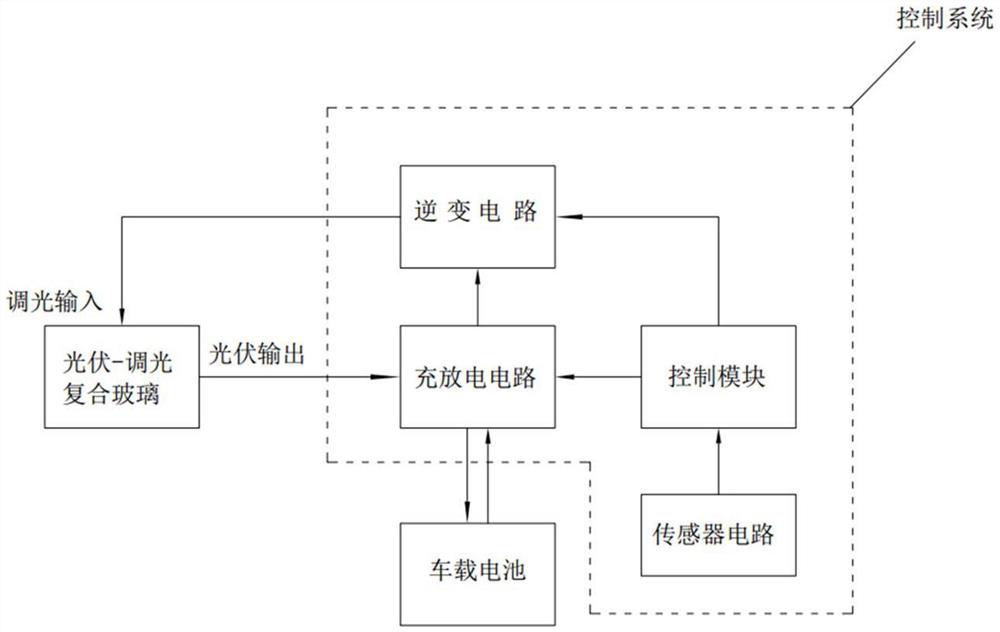

Photovoltaic dimming composite glass and control system thereof

A composite glass and control system technology, applied in photovoltaic power generation, roofing, transportation and packaging, etc., can solve the problems of voltage can not be transposed, affect the electrical output of photovoltaic glass, heavy weight, etc., to avoid the effect of easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe the technical content, the realized purpose and the effect of the present invention in detail, the present invention will be further described below in conjunction with the accompanying drawings and embodiments. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. example.

[0035] In the present invention, the orientations or positional relationships indicated by the terms "upper", "lower", etc. are all based on the orientations or positional relationships shown in the drawings. These terms are mainly used to better describe the present invention and its embodiments, and are not used to limit the indicated devices, elements or constituents to have specific orientations, and thus should not be construed as limiting the present invention.

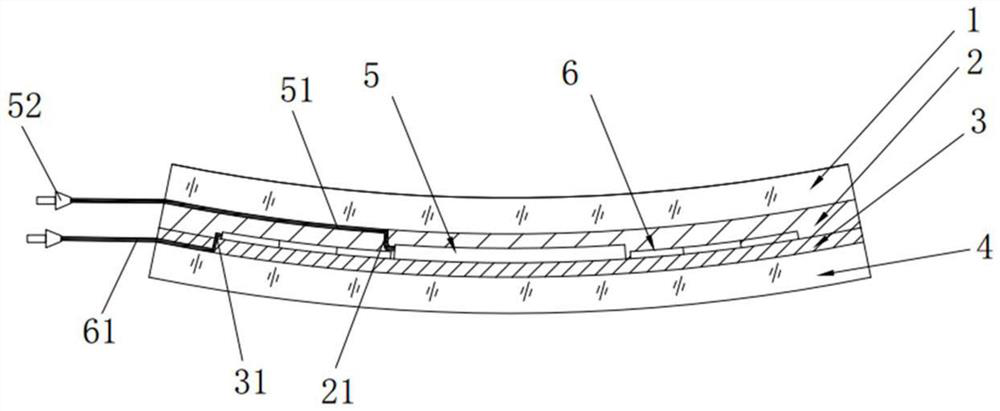

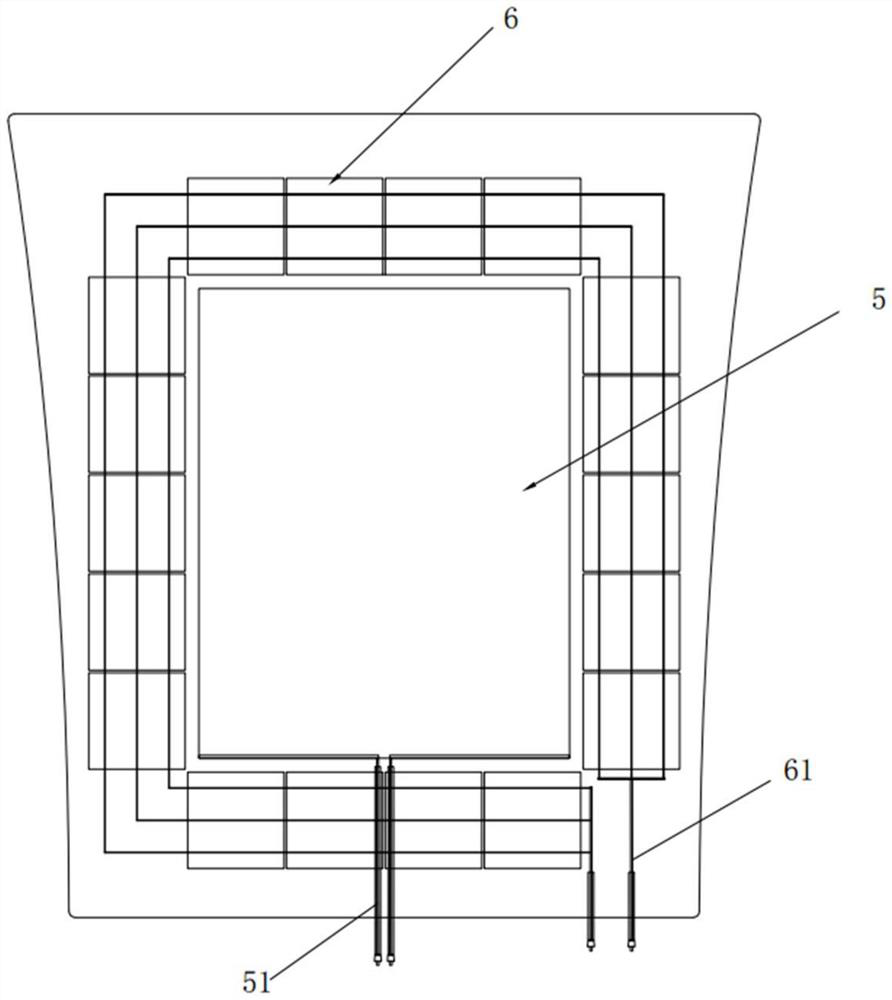

[0036] like figure 1 As shown, the present invention provides a photovoltaic dimming composite glass, including a first light-transmitting plate 1, a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com