Metal material surface electrolytic texturing method

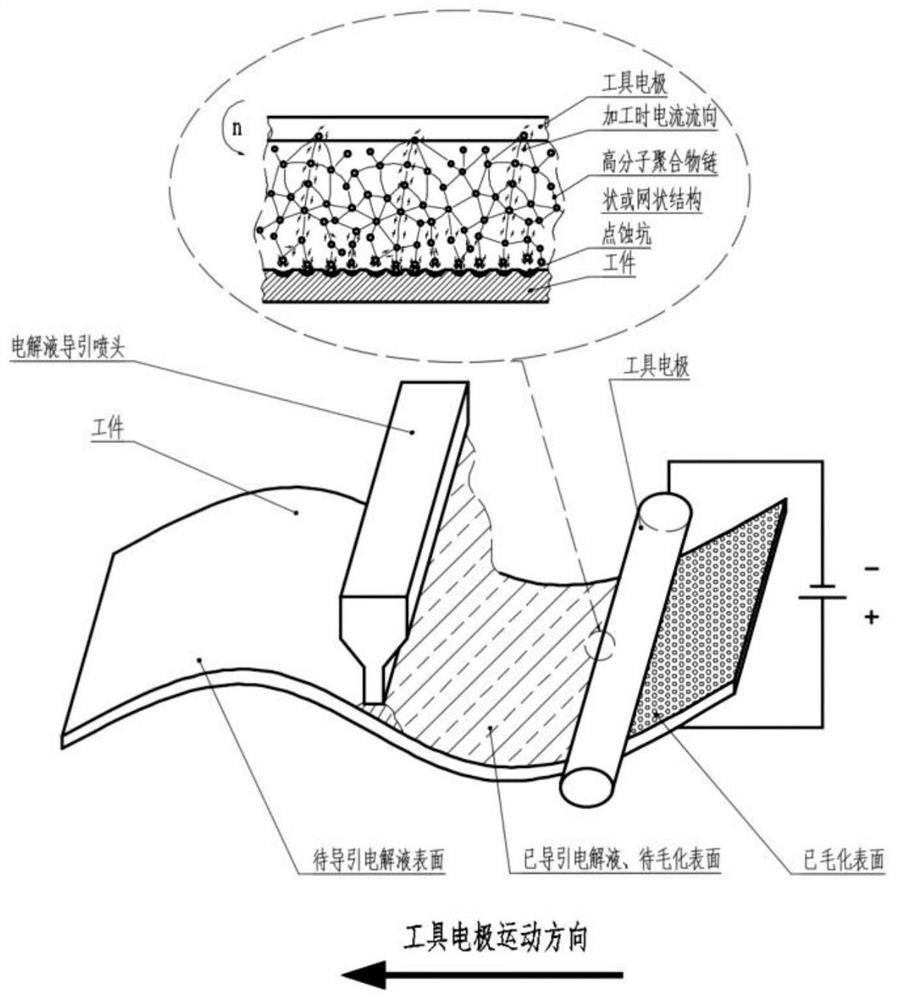

A technology for the surface of metal materials and workpieces, applied in the field of electrolytic texturing of metal materials, can solve problems such as poor localization and uneven texturing effects, and achieve controllable shape, improved energy utilization, and good localization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

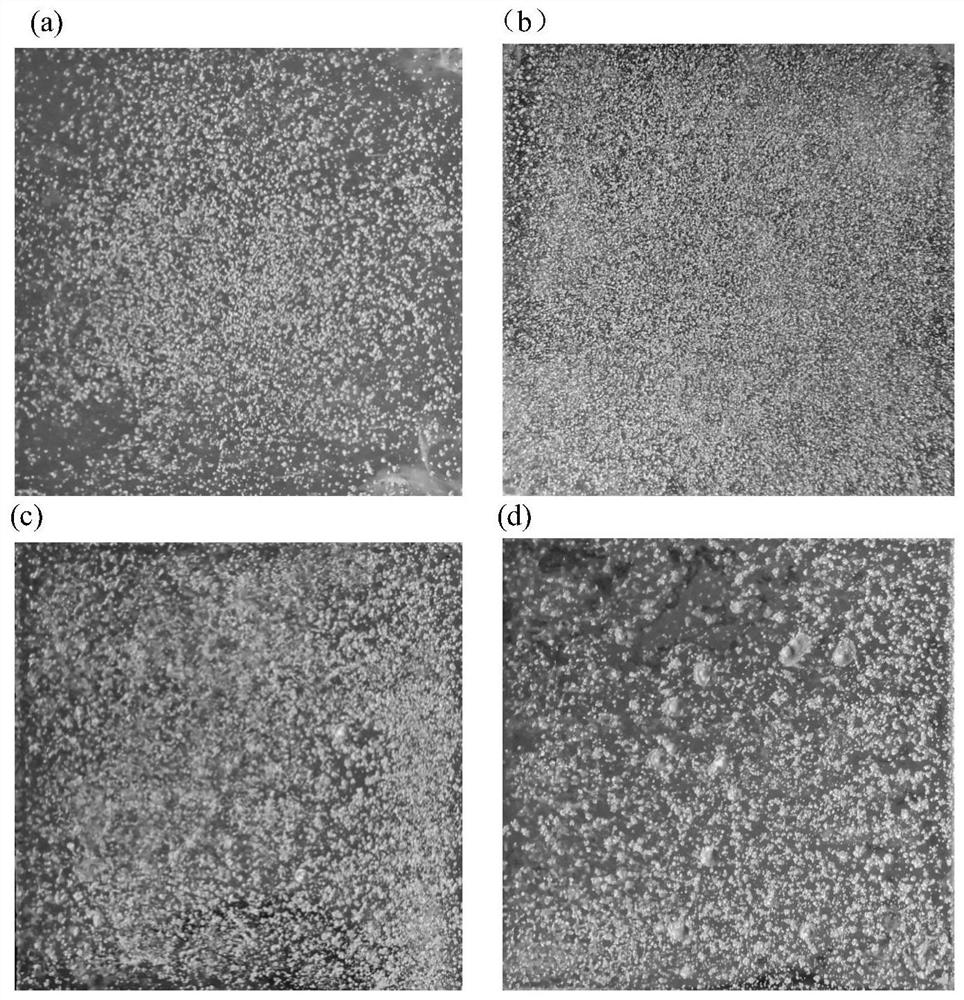

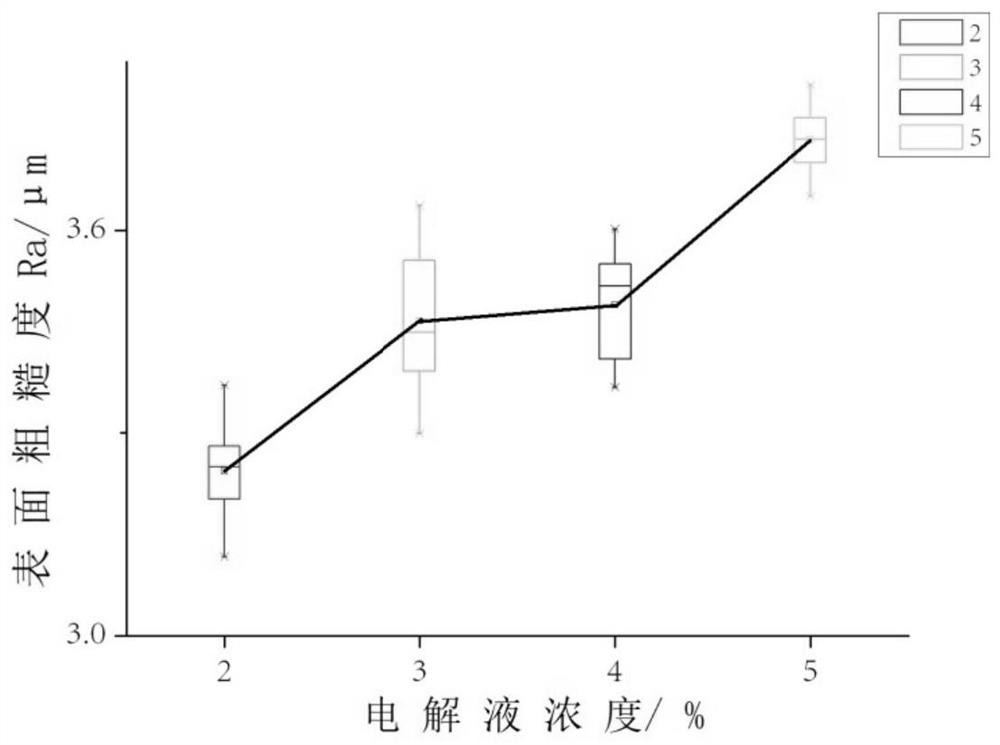

Embodiment 1

[0051] This embodiment provides a method for electrolytic texturing of the surface of metal materials. The power supply voltage is 8V, the duty cycle of the power supply is 20%, the mass fraction of solute in the electrolyte is 2%, the power supply frequency is 1500Hz, and the processing gap is 1.2mm. The speed is 0.8mm / s, the rotation speed of the tool electrode is 500r / min, and the workpiece after surface roughening is obtained.

Embodiment 2

[0053] This embodiment provides a method for electrolytic texturing of the surface of a metal material. Compared with Embodiment 1, the difference is that the mass fraction of the solute in the electrolyte of this embodiment is 3%;

[0054] Other conditions are identical with embodiment 1.

Embodiment 3

[0056] This embodiment provides a method for electrolytic texturing of the surface of a metal material. Compared with Embodiment 1, the difference is that the mass fraction of the solute in the electrolyte of this embodiment is 4%;

[0057] Other conditions are identical with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap