a co 9 the s 8 Nanoparticle composite electrode material and its preparation method and application

A composite electrode and nanoparticle technology, used in hybrid capacitor electrodes, nanotechnology, battery electrodes, etc., can solve the problems of complex synthesis process, high price, scarcity of materials, etc., and achieve simple preparation process, enhanced conductivity, and increased material surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 High temperature treatment of vermiculite + step-by-step impregnation method

[0044] (1) Grind the commercial expanded vermiculite fully through a 200-mesh sieve in a mortar, and collect the product under the sieve (<100 μm) as the finely ground vermiculite;

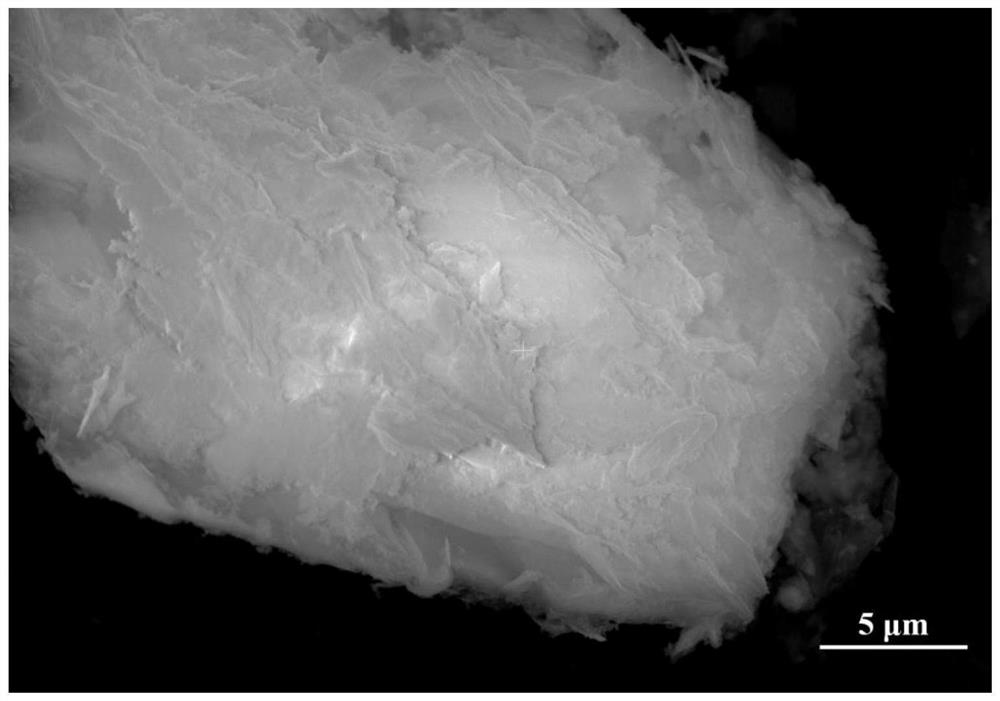

[0045] (2) Weigh 0.51 g of the finely ground vermiculite prepared in step (1), raise the temperature to 900°C in the air at a heating rate of 5°C / min, keep the temperature at a constant temperature for 2 hours, and cool naturally to obtain high-temperature treated vermiculite;

[0046] (3) Weigh 10g of sucrose to prepare a 9.6% sucrose solution as impregnation solution A; place the high-temperature-treated vermiculite prepared in step (2) in 50mL of impregnation solution A for 24 hours, and centrifuge after the impregnation is completed. , keep the lower layer product and dry at 105°C for 12h; after drying, in an inert gas N 2 Under the atmosphere, the temperature was raised at 2°C / min at a constant te...

Embodiment 2

[0052] Embodiment 2 grinds fine vermiculite+step-by-step impregnation method

[0053] (1) Grind the commercial expanded vermiculite fully through a 200-mesh sieve in a mortar, and collect the product under the sieve (<100 μm) as the finely ground vermiculite;

[0054] (2) Weigh 10g of sucrose to prepare a 9.6% sucrose solution by mass as impregnating solution A; place 0.51g of the finely ground vermiculite prepared in step (1) in 50mL of impregnating solution A for 24 hours. Centrifuge, keep the lower layer product and dry at 105°C for 12h; after drying, in an inert gas N 2 Under the atmosphere, the temperature was raised at 2°C / min at a constant temperature of 600°C for 3 hours, and naturally cooled to obtain carbon-coated vermiculite;

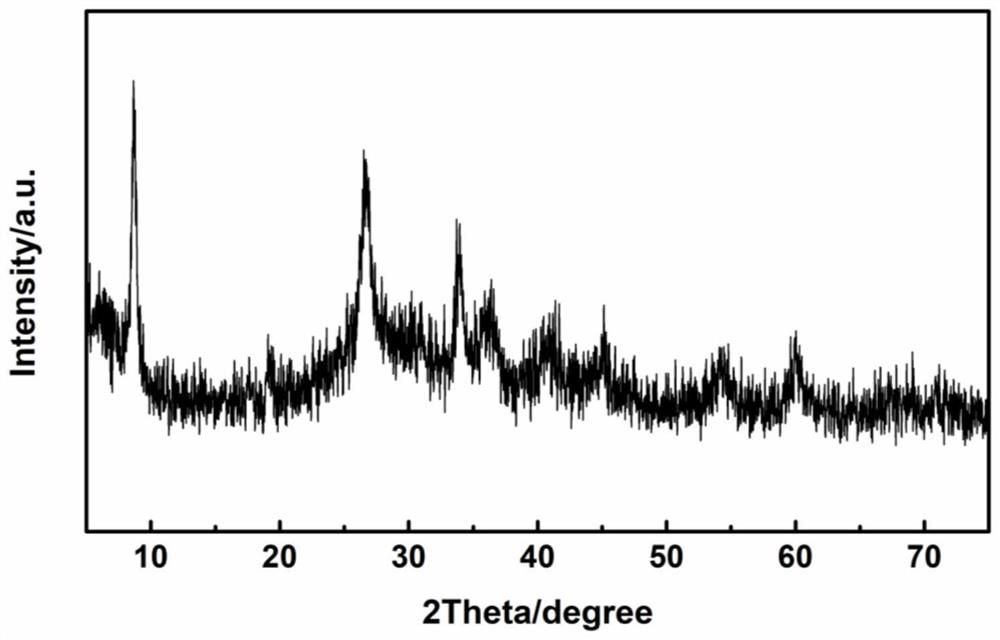

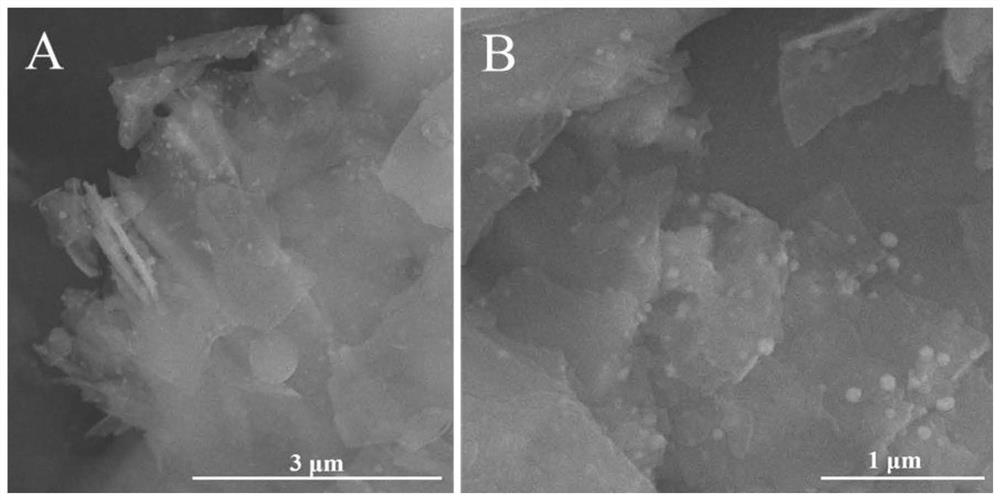

[0055] (3) Weigh 0.48g of cobalt chloride hexahydrate, 0.3g of thiourea and 12g of urea according to the molar ratio of 1:2:100 to prepare 100ml of impregnation solution B. In the impregnation solution B, cobalt chloride hexahydrate and thio...

Embodiment 3

[0059] Example 3 Acid treatment of vermiculite+step-by-step impregnation method

[0060] (1) Grind the commercial expanded vermiculite fully through a 200-mesh sieve in a mortar, and collect the product under the sieve (<100 μm) as the finely ground vermiculite;

[0061] (2) Weigh 0.51g of the finely ground vermiculite prepared in step (1), stir it with 200mL of 2mol / L hydrochloric acid at 80°C for 24 hours, filter it, wash it with water until it is neutral, and dry it at 70°C to obtain the acid-treated vermiculite ;

[0062] (3) Weigh 10g of sucrose to prepare a 9.6% sucrose solution by mass as impregnating solution A; place the hydrochloric acid-treated vermiculite prepared in step (2) in 50mL of impregnating solution A for 24 hours, and then centrifuge , keep the lower layer product and dry at 105°C for 12h; after drying, in an inert gas N 2 Under the atmosphere, the temperature was raised at 2°C / min at a constant temperature of 600°C for 3 hours, and naturally cooled to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com