Wastewater treatment device

A wastewater treatment and reaction box technology, which is applied in multi-stage water treatment, water/sewage treatment, degassed water/sewage treatment, etc., can solve the problem of low purification efficiency of wastewater treatment equipment, low purification efficiency, and unfavorable use by people, etc. problem, to achieve the effect of simple structure, ensuring mixing efficiency, and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

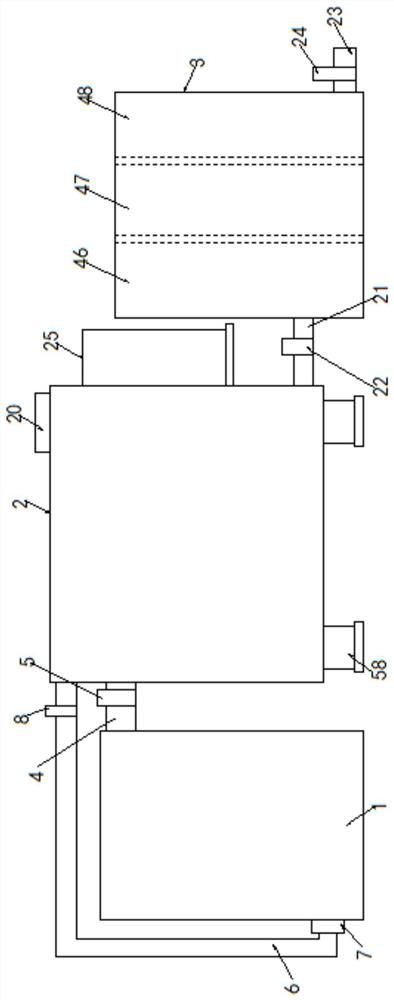

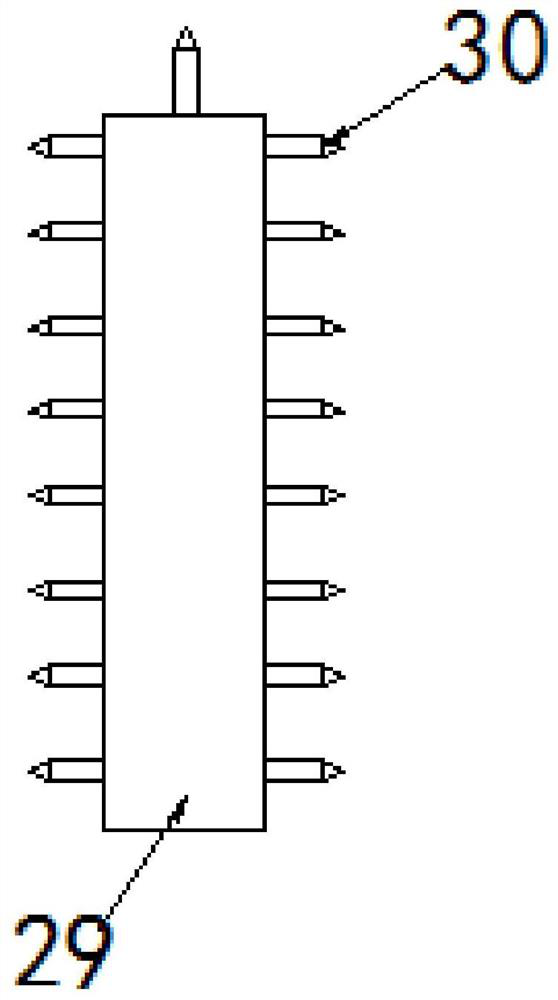

[0037] Embodiment one, such as Figure 1-11 As shown, a wastewater treatment device according to an embodiment of the present invention includes a storage tank 1, a reaction tank 2 and a purification tank 3, and the top side of the storage tank 1 is connected to the reaction tank 2 through a connecting pipe 2 4. One side of the top is fixed, and a valve two 5 is fixed on the connecting pipe two 4, and the bottom of the side of the storage tank 1 away from the connecting pipe two 4 is connected to the top of the reaction box 2 through a connecting pipe one 6 , the connecting pipe-6 is connected with the storage tank 1 through a water pump 7, the end of the connecting pipe-6 close to the reaction tank 2 is fixed with a valve-8, and the inner top of the storage tank 1 is fixed with Chute one 9, in the described chute one 9, slide and be connected with the slide plate 10 that is matched with described chute one 9, the bottom end of described slide plate 10 is fixed with electric t...

Embodiment 2

[0038] Embodiment two, such as figure 1 and 9 As shown, the inside of the purification box 3 is fixed with activated carbon adsorption layer 46, photocatalyst sterilization layer 47 and purification layer 48 successively near the side of the reaction box 2; The bar is connected with the side wall of the storage box 1; the activated carbon adsorption layer 46 arranged in turn through the purification box 3 can adsorb the substances in the sewage, and the photocatalyst sterilization layer 47 can be sterilized simultaneously, and the purification layer 48 can be used for further cleaning. purification treatment.

Embodiment 3

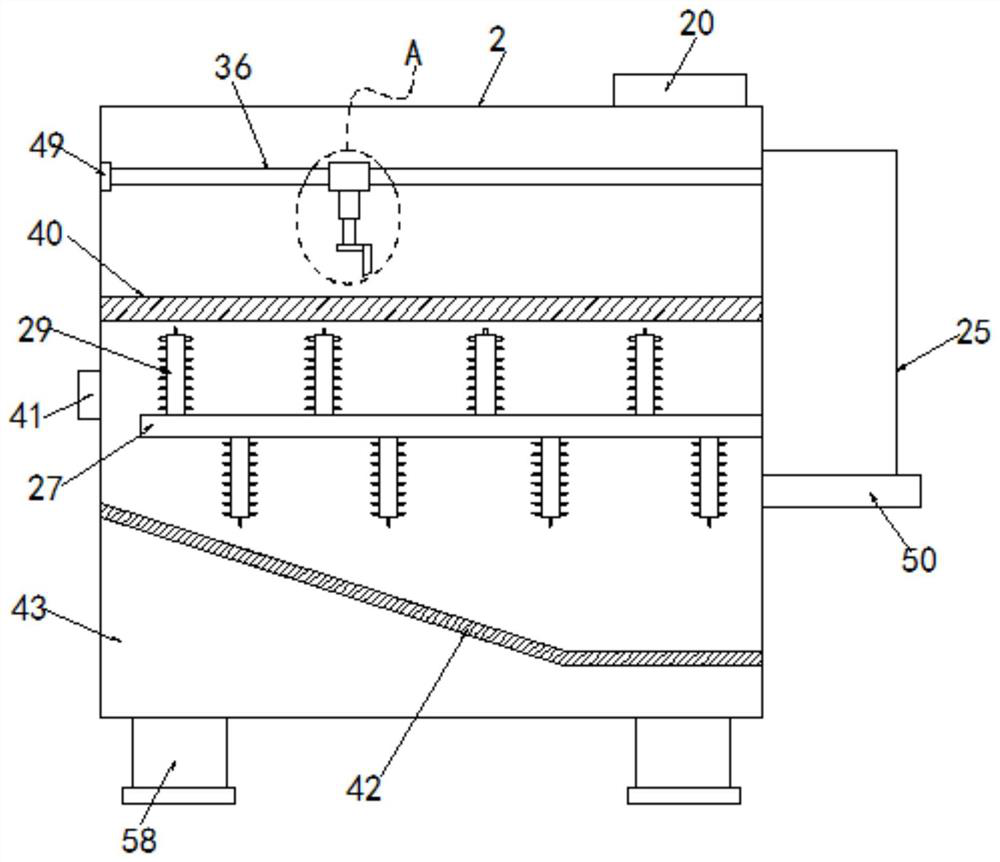

[0039] Embodiment three, such as figure 2 and 5 As shown, the end of the threaded rod one 36 away from the pulley two 35 is fixed in the inside of the reaction box 2 through a fixed sleeve three 49, and the threaded rod one 36 and the fixed sleeve three 49 are passed through a bearing Connection; the bottom of the fixed box 25 is fixed on the outer side of the reaction box 2 by the support plate two 50, and the bottom end of the motor one 26 is fixed on the inside of the fixed box 25 by the support plate one 51 Bottom: Threaded rod-36 can be fixed more stably and firmly in the inside of reaction box 2 by fixing sleeve three 49, and bearing can facilitate the rotation of threaded rod-36 simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com