Smelting method and smelting device for iron-based ores

A mineral and iron-based technology, applied in the direction of reducing gas emissions, which can solve the problems of low energy consumption, short process, and inability to take into account high iron recovery rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] Using vanadium titanomagnetite as raw material, the composition is shown in the following table (TFe represents the total iron content in the material), in wt%:

[0098]

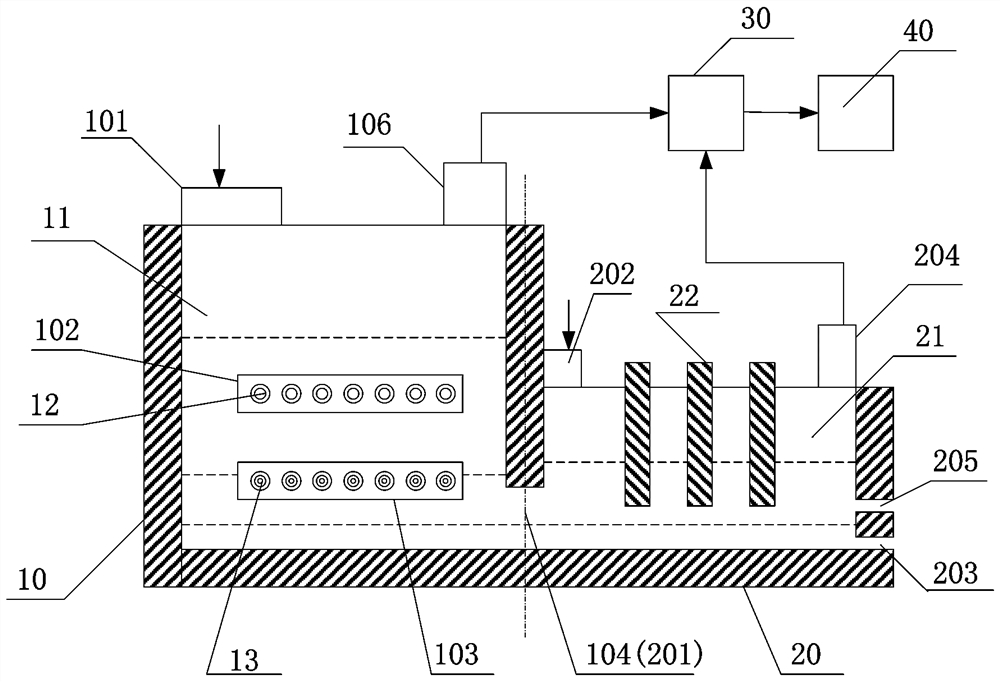

[0099] use figure 1 The jet smelting unit-electrothermal reduction unit integrated equipment shown, the jet smelting area is provided with an upper-layer spray gun and a lower-layer spray gun, the height of the slag layer of the jet smelting in the jet smelting area is denoted as H, and the distance between the nozzle of the upper spray gun and the surface of the slag layer is denoted as H. The distance is denoted as h 1 , the distance between the nozzle of the lower spray gun and the surface of the slag layer is recorded as h 2 , where h 1 / H is 1 / 4, h 2 / H is 3 / 4.

[0100] The massive vanadium titanomagnetite and quicklime are put into the jet smelting area through the belt conveyor, and 15.80kg quicklime is added to each ton of vanadium titanite. The material enters the jet smelting area to ...

Embodiment 2

[0106] Using vanadium titanomagnetite as raw material, the composition is shown in the following table:

[0107]

[0108] use figure 1 In the shown integrated equipment of jet melting unit and electrothermal reduction unit, the height of the slag layer of jet melting in the jet melting zone is denoted as H, and the distance from the nozzle of the upper spray gun to the surface of the slag layer is denoted as h 1 , the distance between the nozzle of the lower spray gun and the surface of the slag layer is recorded as h 2 , where h 1 / H is 1 / 4, h 2 / H is 3 / 4.

[0109] The massive vanadium titanomagnetite is put into the jet molten pool through the belt conveyor, and the material enters the jet melting zone for melting and reduction. The temperature of the molten pool in the jet melting zone is about 1650℃.

[0110] Oxygen and natural gas are injected into the upper spray gun in the upper part of the jet smelting area, and 126Nm of oxygen needs to be injected per ton of va...

Embodiment 3

[0115] Using sea sand ore as raw material, the composition is shown in the following table:

[0116]

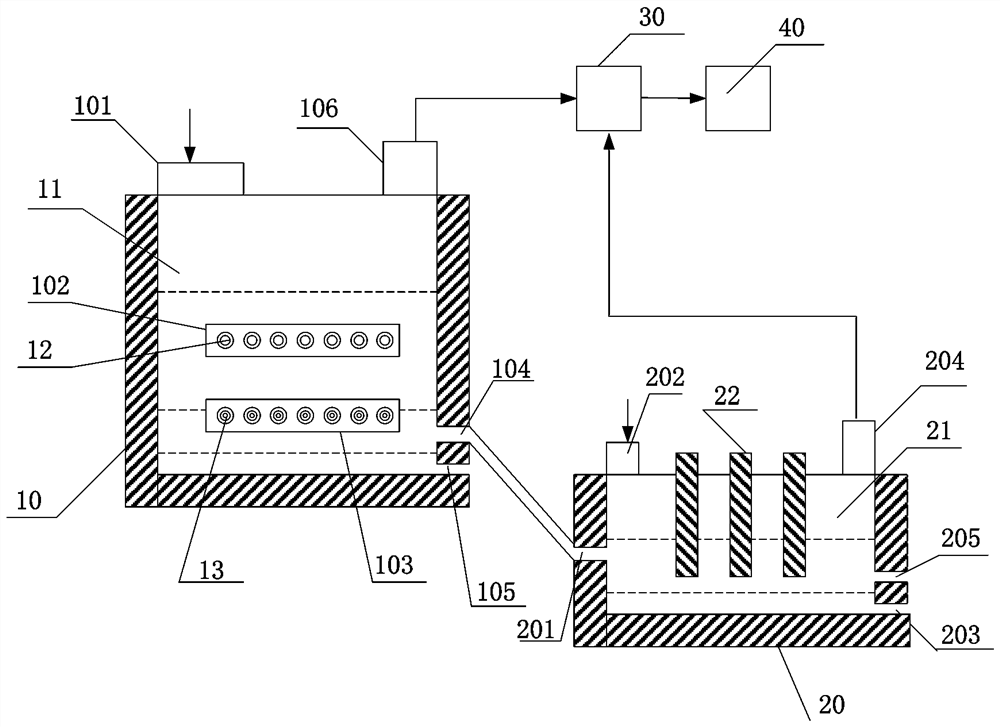

[0117] use figure 2 The shown jet smelting unit-electrothermal reduction unit is a separate equipment, the jet smelting area is provided with an upper-layer spray gun and a lower-layer spray gun, the height of the slag layer of the jet smelting in the jet smelting area is denoted as H, and the distance between the nozzle of the upper spray gun and the surface of the slag layer is denoted as H. The distance is denoted as h 1 , the distance between the nozzle of the lower spray gun and the surface of the slag layer is recorded as h 2 , where h 1 / H is 1 / 4, h 2 / H is 3 / 4.

[0118] The sea sand ore and quicklime are mixed according to the ratio of 1000:32. After mixing, the material is put into the jet molten pool through the belt conveyor, and the material enters the jet melting zone for melting and reduction. The temperature of the molten pool in the jet melting zone is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com