Process for preparing high-purity hydrogen through reforming coupling chemical looping of methane-containing combustible gas and application

A chemical reaction and hydrogen production reactor technology, applied in the field of thermochemical hydrogen production, can solve the problems of low product purity and complex preparation process, and achieve the effects of safe and reliable operation, simple operation and improved reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

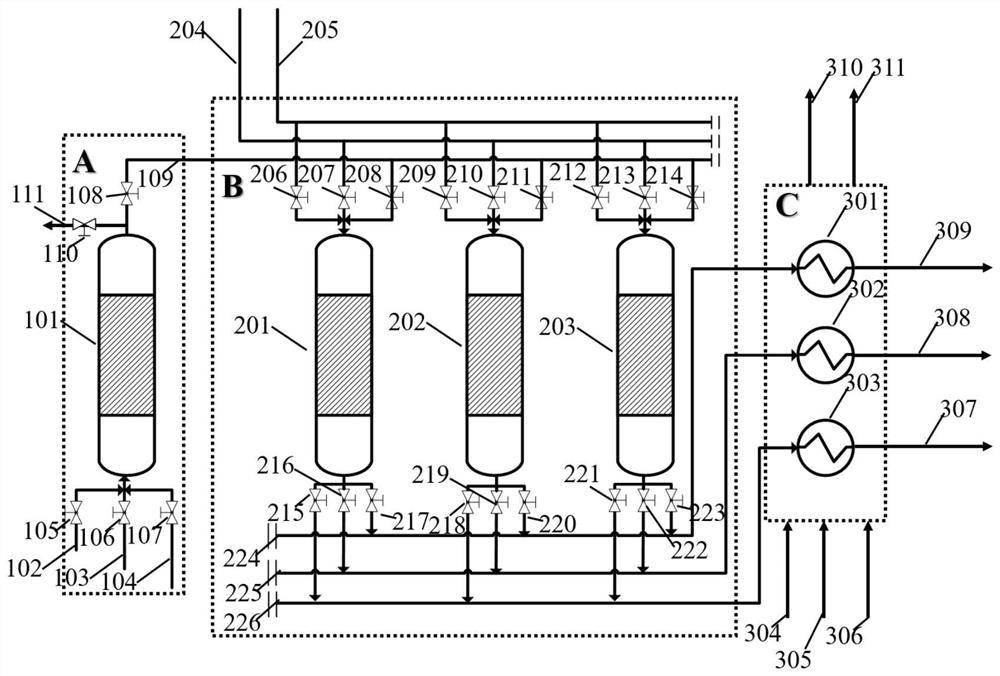

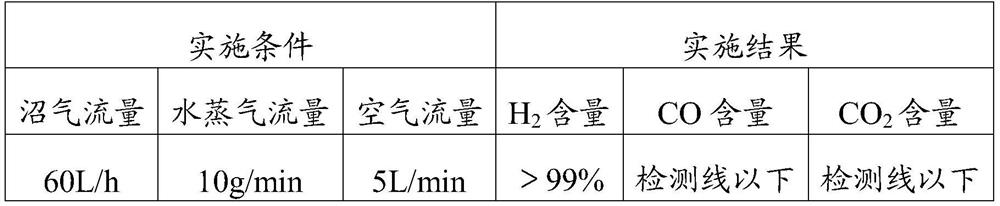

[0075] This embodiment provides a method for preparing high-purity hydrogen by coupling chemical chain reforming of combustible gas containing methane and a reforming catalyst of combustible gas containing methane, such as figure 1 As shown, the methane-containing combustible gas is firstly reformed in a fixed-bed reforming reactor, and then the reformed gas is used as the fuel of the chemical looping hydrogen production reactor to prepare high-purity hydrogen. The specific method is as follows:

[0076] The preparation of the reforming catalyst in the present invention is specifically as follows: firstly, the water absorption rate of the commercial MgO powder is measured to be 4.72mL / gMgO. According to Pt: (Pt+Ni+MgO) mass percentage 1%, Ni: (Pt+Ni+MgO) mass percentage is 10%, take corresponding nickel nitrate hexahydrate and chloroplatinic acid, and corresponding deionized Make a solution with water. After the dissolution is completed, mix the salt solution and MgO powder at...

Embodiment 2

[0089] This example uses the same process as Example 1 to produce hydrogen, the only difference being that hydrogen is produced without the third step of air oxidation of the oxygen carrier.

[0090] The technical effect contrast of table 2 embodiment 1 and embodiment 2

[0091] craft The composition of the tail gas of the reduction reactor after cooling Process heat absorption and release Example 1 100%CO 2

energy self-sustaining Example 2 11% CO, H 2 、CH 4 and 89% CO 2

Need extra energy

[0092] As can be seen from the comparison of Example 1 and Example 2, when the oxygen carrier is iron, iron needs to be further oxidized to obtain better technical effects; There is no need to further oxidize the oxygen carrier;

[0093] After water vapor oxidation, only Fe can be produced 3 o 4 , Fe 3 o 4 When reacting with the reformed gas, part of the reformed gas does not participate in the reduction reaction, resulting in waste of fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com