Energy-saving type tunnel advanced small pipe fast-assembly grout stopping structure

An advanced small conduit and energy-saving technology, applied in the direction of tunnels, tunnel linings, shaft equipment, etc., can solve the problems of prolonging the tunnel cycle construction time, violations, and fillings that cannot be formed, and achieve the effect of being easy to promote and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

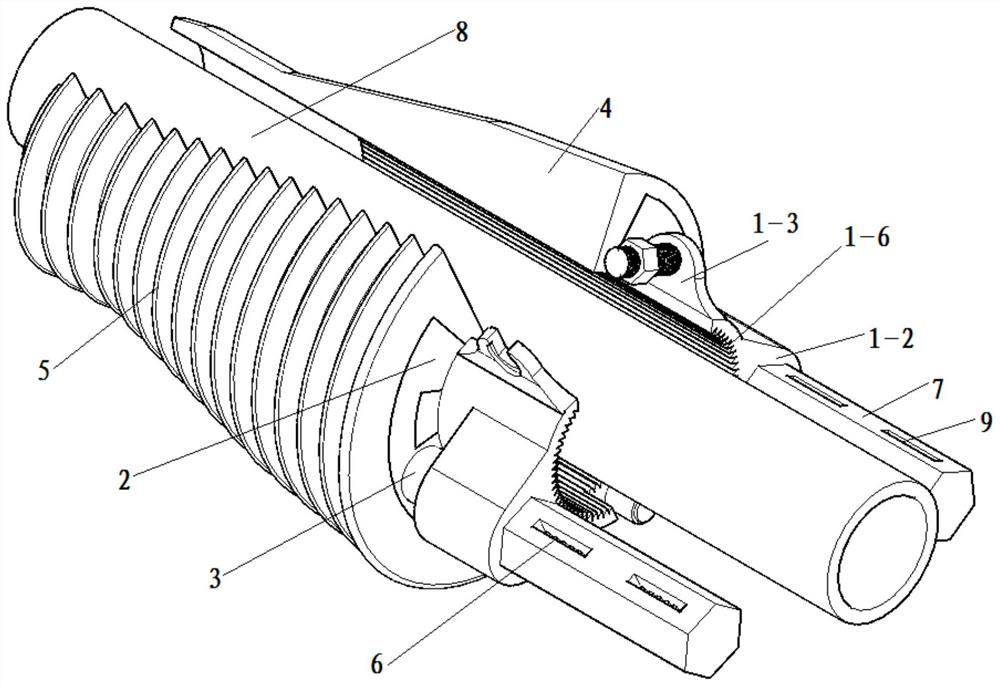

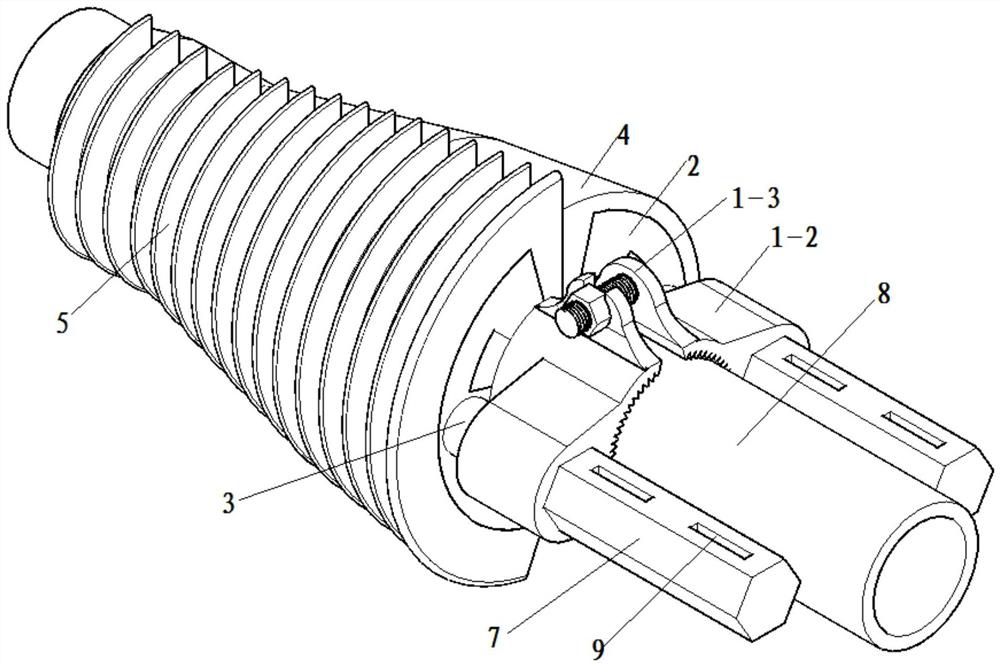

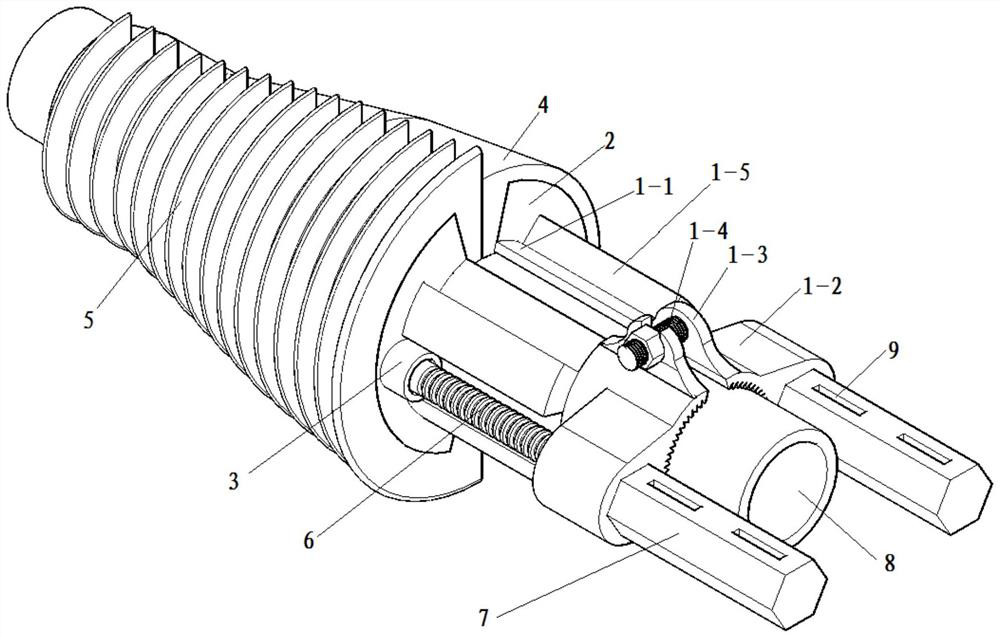

[0037] Such as Figure 1 to Figure 5 As shown, the present invention includes a force-holding fixture clamped at one end of the leading small conduit 8 protruding from the palm surface, a sliding mold sleeve sleeved on the outside of the force-holding fixture and slidingly fitted with the force-holding fixture, and wrapped in the force-holding fixture. The elastic stopper on the outside of the sliding die sleeve and used to block the gap between the leading small conduit and the hole wall, the holding force clamp includes two matching holding force clamps, and the holding force clamp includes Splint 1-1, guide ear plate 1-2 installed on the end of holding force splint 1-1 away from the palm face and slideway 1-5 installed on holding force splint 1-1, guide ear plate 1-2 and sliding There is a gap between the lanes 1-5, and threaded holes 1-7 are provided on the guide ear plate 1-2. The sliding mold cover includes two matching sliding mold frames 2, and the sliding mold frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com