Optical path fault detection device and detection method of fiber laser

A fiber laser and fault detection technology, which is applied to lasers, laser parts, phonon exciters, etc., can solve the problems of detection system misjudgment, optical fiber fluctuations, and the location of optical path faults that cannot accurately locate the laser power, so as to avoid missed alarms Or false alarm, reduce the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention and not to limit the present invention, that is, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

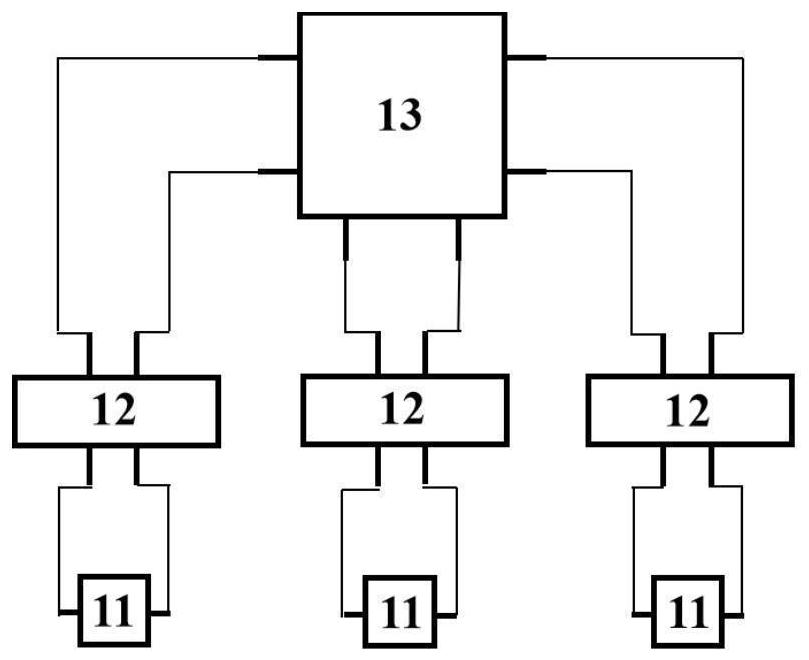

[0024] Such as figure 1 As shown, the fiber laser optical path fault detection device provided by the present invention is composed of an optical sensor module 11, a power supply module 12, and a main control chip 13. The power module 12 and the light sensor module 11 are arranged in a pair. The power module 12 is used in the device to apply electrical signals to the light sensor module 11, and at the same time transmit the level signal between the two electrodes of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com