Stretchable multi-core conductive element and preparation method thereof, stretchable cable and stretchable capacitive sensor

A capacitive sensor and conductive element technology, applied in the direction of extensible conductor cables, electrical components, extensible conductors, etc., can solve the problems that the sensor cannot obtain stretching changes, signal bending deformation interference, etc., to achieve beautiful appearance, cable The effect of roundness and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

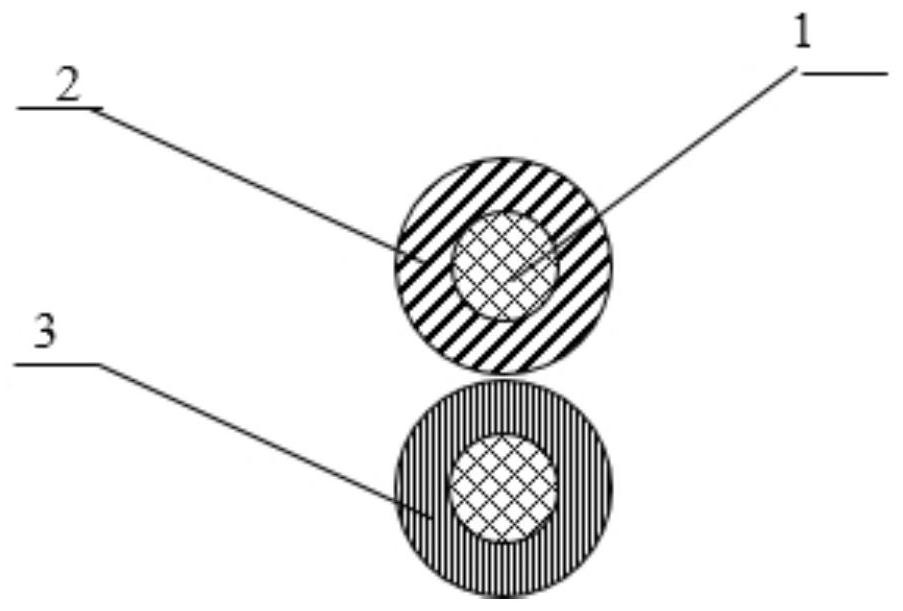

[0040] In this example, if figure 1 , 2 As shown, the liquid metal 1 is filled in the elastic tube 2 and the elastic tube 3 respectively to form two stretchable wires. Along the length direction, the two stretchable wires are intertwined with each other to form a stretchable multiple wire structure with a twisted pair structure. core conductive element. Wherein, the liquid metal is made of GaInSn alloy, and the elastic tube 2 and the elastic tube 3 are both made of thermoplastic elastic material SEBS.

[0041] The preparation method of the stretchable multi-core conductive element is as follows:

[0042]Using extruder equipment and extrusion die, the extrusion die is two hollow pipes with side-by-side double needles socketed outside, using the die to directly extrude the SEBS elastic pipe; then directly inject liquid metal into the pipe ; Afterwards, it is pulled by an external winding device, and the two wires are wound with each other to form a figure 2 The stretchable ...

Embodiment 2

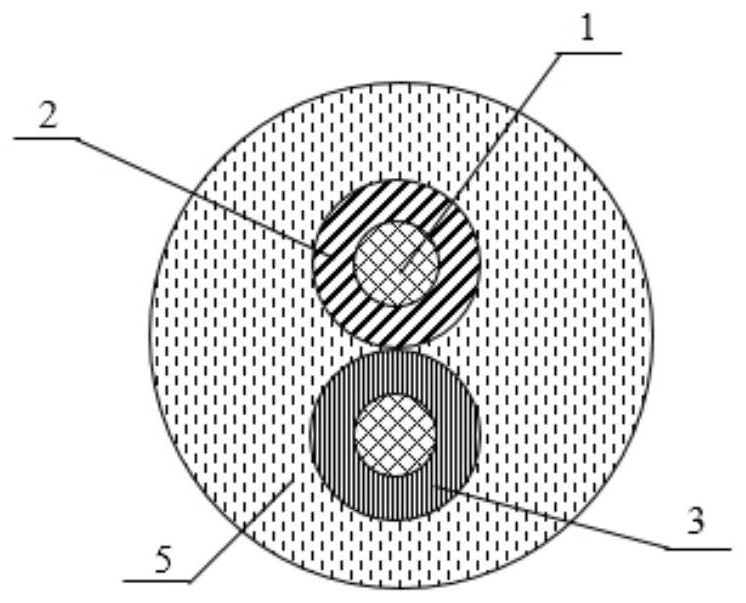

[0046] In this example, if image 3 , 4 As shown, the liquid metal 1 is filled in the elastic tube 2 and the elastic tube 3 respectively to form two stretchable wires. Along the length direction, the two stretchable wires are interlaced and intertwined to form a twisted pair structure. Cover the elastic protective layer 5 to obtain a stretchable multi-core conductive element.

[0047] Among them, the liquid metal is made of GaInSn alloy, the elastic tube 2 and the elastic tube 3 are made of thermoplastic elastic material SEBS, and the elastic protective layer 5 is made of polyester fiber yarn woven into an elastic structure.

[0048] The preparation method of the stretchable multi-core conductive element is as follows:

[0049] Using extruder equipment and extrusion die, the extrusion die is two hollow pipes with side-by-side double needles socketed outside, using the die to directly extrude the SEBS elastic pipe; then directly inject liquid metal into the pipe Afterwards, ...

Embodiment 3

[0053] In this example, if Figure 5 , 6 As shown, the liquid metal 1 is filled in the elastic tube 2 and the elastic tube 3 respectively to form two stretchable wires. Along the length direction, the two stretchable wires are interlaced and intertwined to form a twisted pair structure. The elastic shielding layer 4 is covered, and the outer periphery of the shielding layer 4 is covered with an elastic protective layer 5 to obtain a stretchable multi-core conductive element.

[0054] Among them, the liquid metal is made of GaInSn alloy, the elastic tube 2 and the elastic tube 3 are made of thermoplastic elastic material SEBS, the elastic shielding layer 4 is made of GaInSn alloy, and the elastic protective layer 5 is made of thermoplastic elastic material SEBS.

[0055] The preparation method of the stretchable multi-core conductive element is as follows:

[0056] Adopt extruder equipment, adopt extrusion mold, described extrusion mold is two hollow tube bodies that are sock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com