Method for preparing regenerated neodymium-iron-boron magnet from sintered neodymium-iron-boron slag

A neodymium-iron-boron and slag technology, which is used in the manufacture of magnetic objects, inductors/transformers/magnets, magnetic materials, etc., can solve the problems of cumbersome process, high manufacturing cost, environmental pollution, etc., and achieves simple process, low manufacturing cost, short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

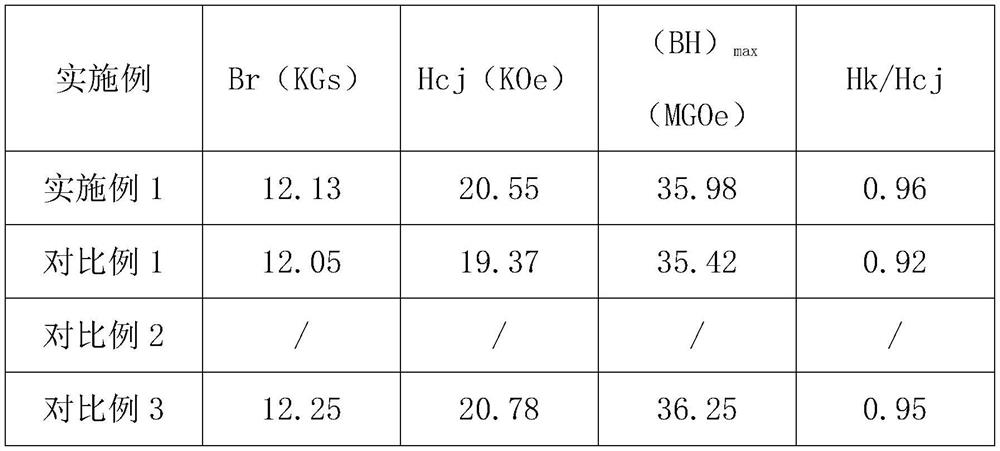

Examples

Embodiment 1

[0018] A method for preparing NdFeB by regeneration of sintered NdFeB slag, the preparation method comprising the following steps:

[0019] (1) Anti-oxidation treatment of slag: Cool the slag with argon gas when opening the smelting furnace door, so that the slag is cooled to below 60°C, and immediately put the slag into a sealed bucket and fill it with nitrogen for protection.

[0020] (2) Slag remelting: quickly put the nitrogen-protected slag into the vacuum plasma furnace, close the furnace body, evacuate to below 5Pa, and then fill it with argon to -0.05MPa; start the plasma arc and induction heating power supply to the slag Carry out heating and remelting, the heating rate is 20°C / s, and the remelting temperature is 1600°C. After the slag is melted, it is stirred to make the harmful substances in the slag float up, and after the slag no longer floats up, it is refined for 4 minutes to cast the slag alloy ingot.

[0021] (3) Proportioning raw materials: The composition a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com