A kind of electronic device heat dissipation structure with three-dimensional network structure and manufacturing method

A mesh structure and three-dimensional mesh technology are applied in the field of heat dissipation structure and manufacturing of electronic devices to achieve the effects of reducing mutual blockage, improving heat exchange efficiency and increasing heat exchange area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in further detail below:

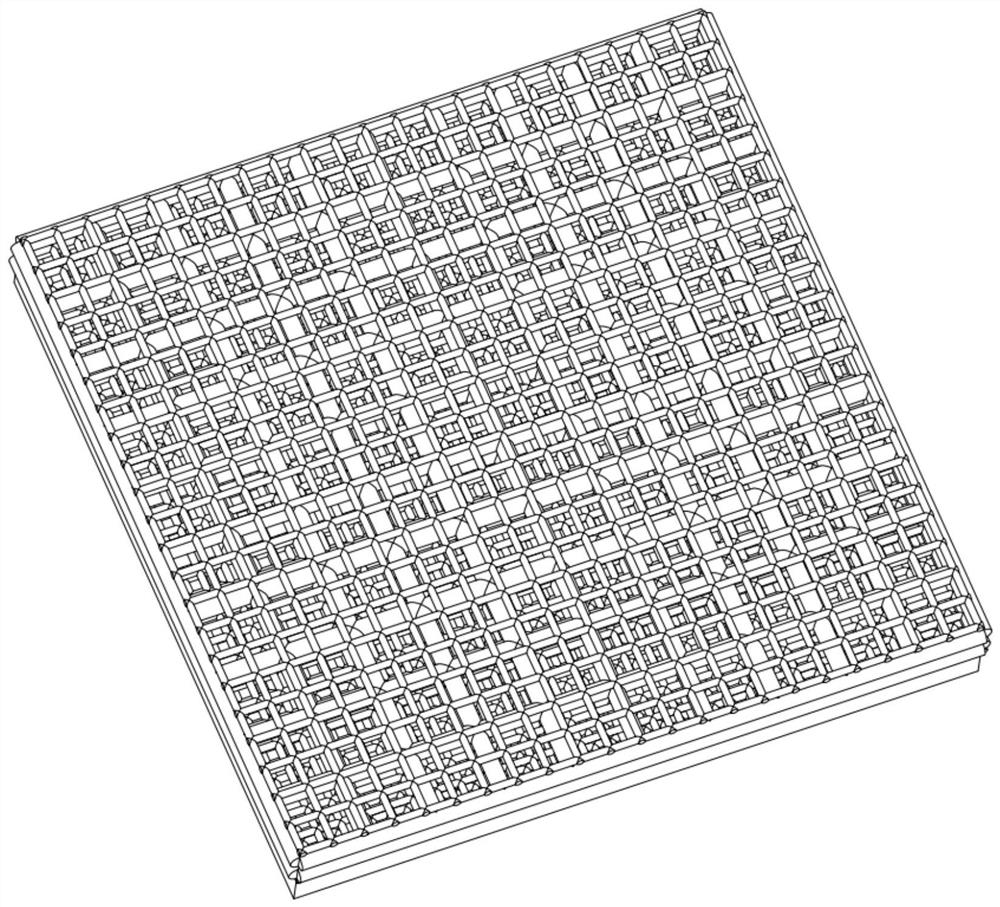

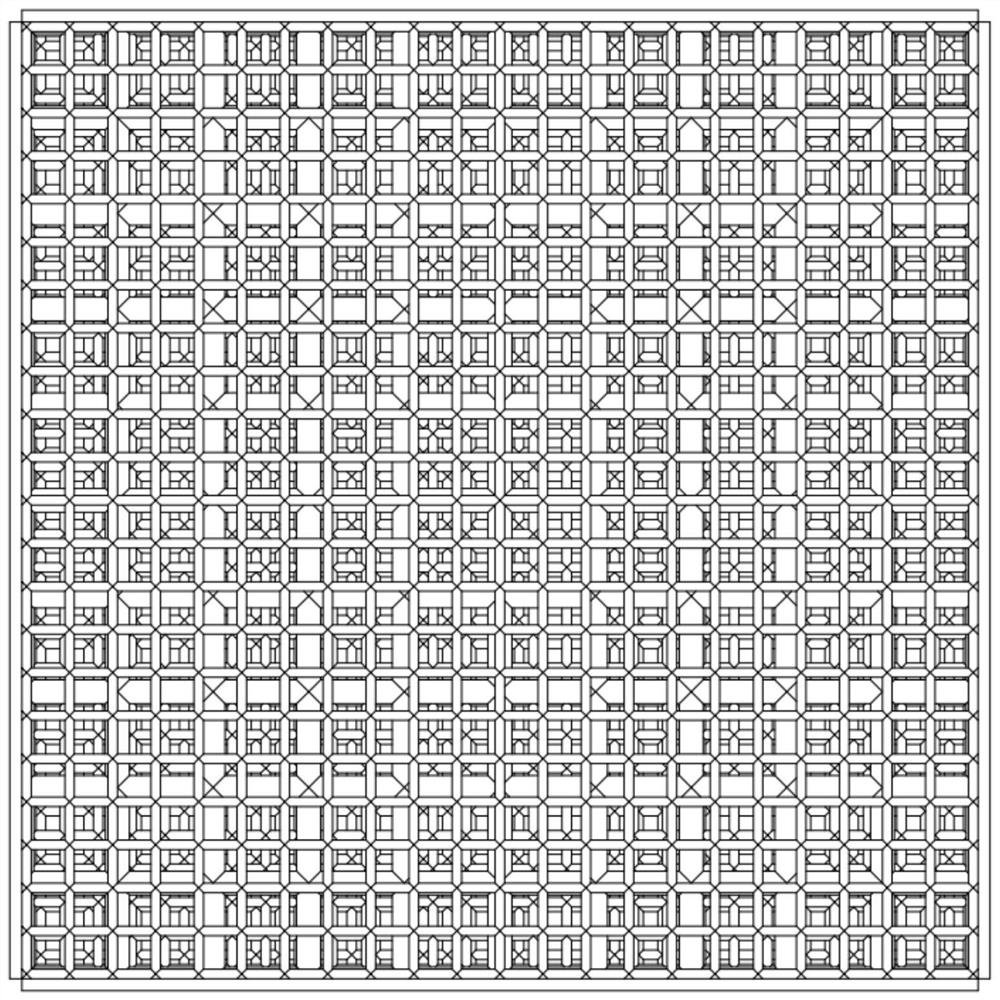

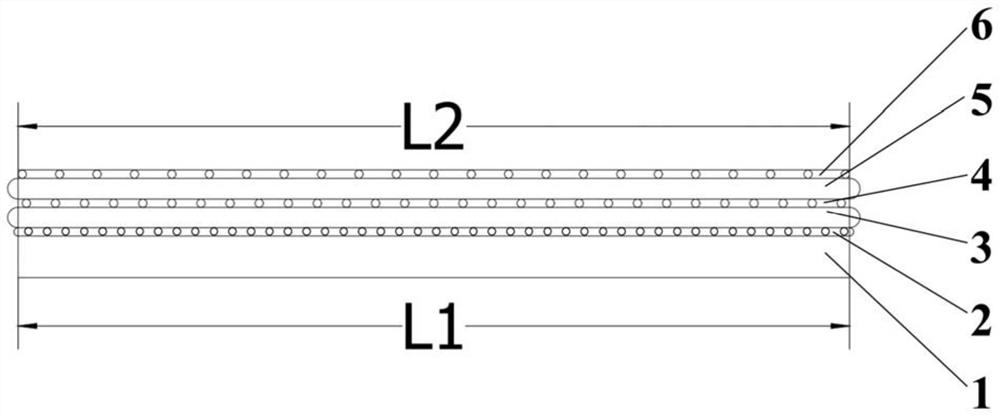

[0046] A heat dissipation structure of an electronic device with a three-dimensional network structure includes a heat dissipation plate 1, a multi-layer micron-level network structure, and a multi-layer skeleton. The heat dissipation plate 1 is provided with a multi-layer micro-scale network structure, and the multi-layer micro-scale network structure is decorated with a nano-scale micro structure (the heat dissipation structure of the electronic device with the three-dimensional network structure is put into the modification solution, and the multi-layer micro-scale network structure is modified with a nano-scale micro structure. growth of nanoscale microstructures on a scale network structure). Among them, the material of the heat dissipation plate 1 and the multi-layer micron-level network structure is copper, which has good thermal conductivity. The length and width of the heat dissipation plate 1 are b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com