Layered composite solid electrolyte as well as preparation method and application thereof

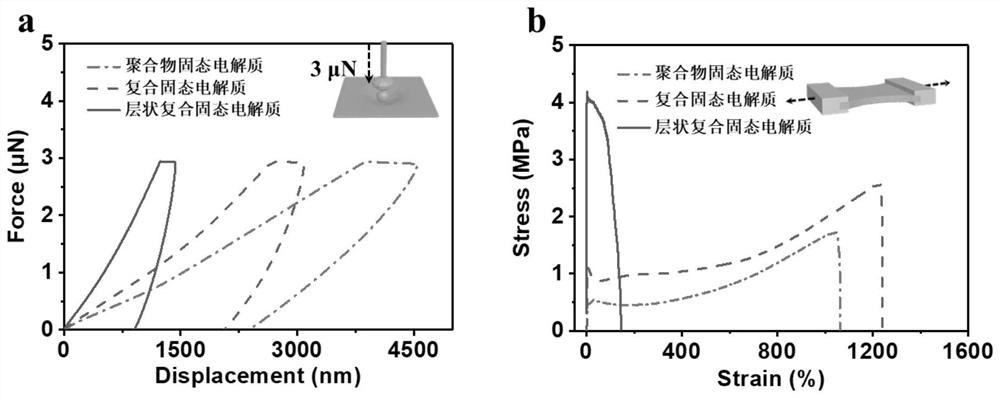

A solid electrolyte and layered composite technology, which is applied in the direction of electrolyte, non-aqueous electrolyte battery, electrolyte immobilization/gelation, etc., can solve the problems of low mechanical strength, low ionic conductivity, large specific surface resistance, etc., and achieve improvement Effects of mechanical strength, improvement of ionic conductivity, and reduction of specific surface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

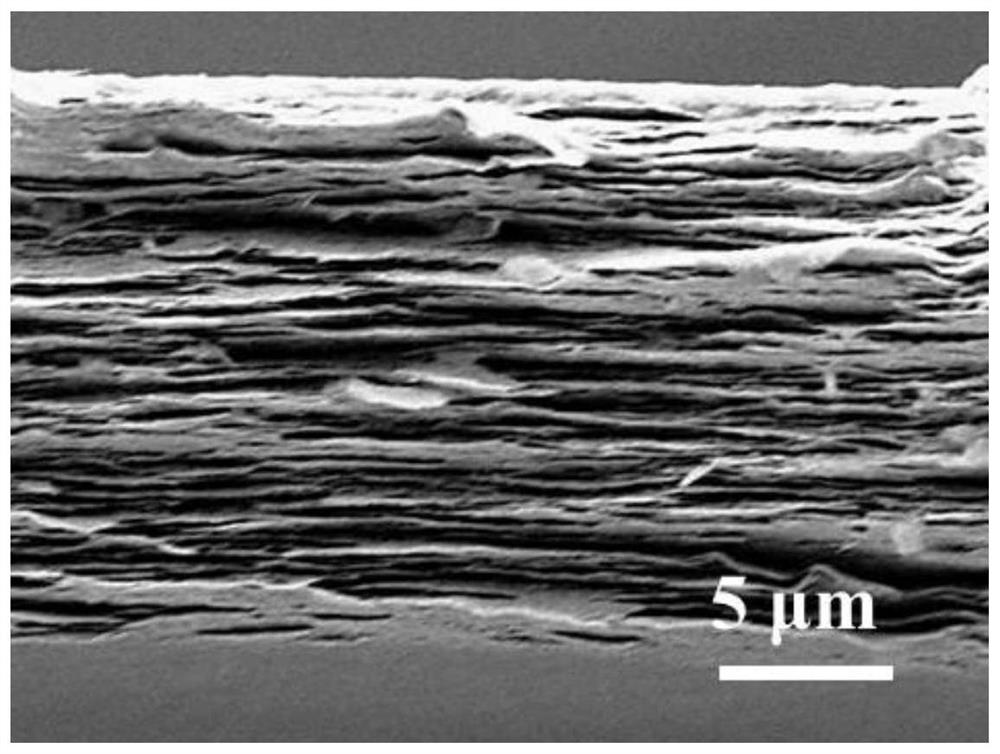

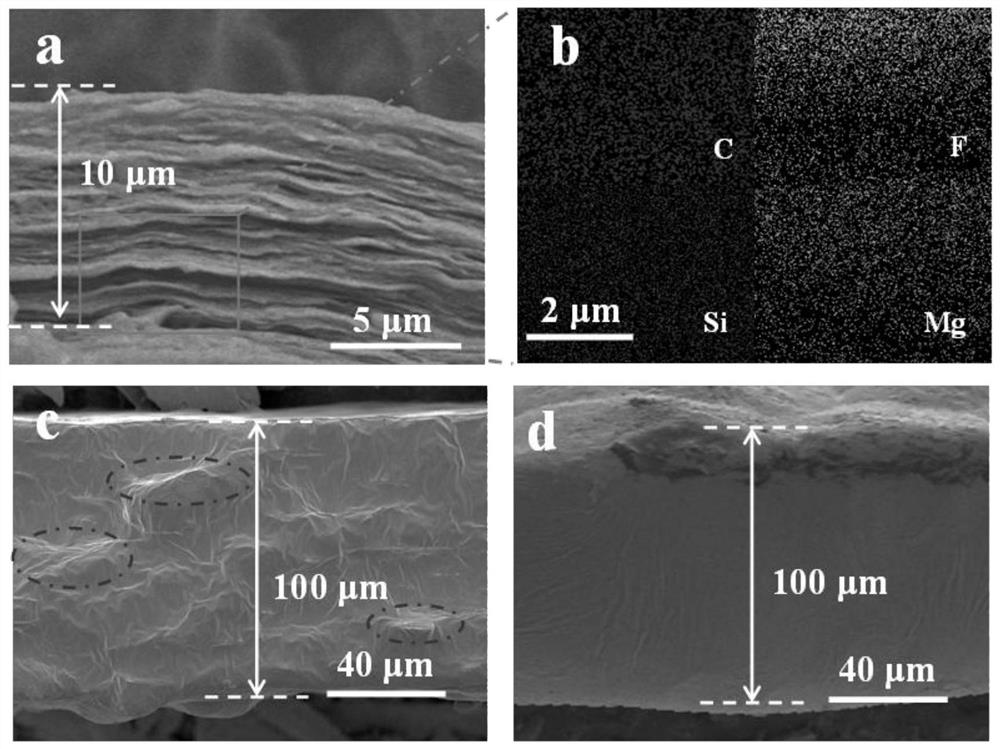

[0040] A layered composite solid electrolyte, the preparation method is as follows:

[0041] 1) Soak 0.5 g of vermiculite in 100 mL of saturated NaCl solution, stir at 120 °C for 24 h, and wash the sodium ion-intercalated vermiculite five times with deionized water. Then 100 mL of 2 mol / L LiCl solution was added, stirred at 120 °C for 24 h, and the lithium-ion intercalated vermiculite was repeatedly washed 5 times with deionized water. Finally, ultrasonically disperse in deionized water for 30 min, and centrifuge at 8000 r / min for 10 min to obtain a vermiculite nanosheet dispersion, in which the concentration of vermiculite nanosheets is 0.1 mg / mL.

[0042] 2) Take 163 mL of the vermiculite nanosheet dispersion in 1) and add it to the suction filtration device, and perform suction filtration at a suction filtration pressure of 0.2 bar, so that the vermiculite nanosheets will slowly self-stack on the basement membrane to obtain layered vermiculite stone frame.

[0043]3) Put ...

Embodiment 2

[0048] A layered composite solid electrolyte, the preparation method is as follows:

[0049] 1) The preparation of the vermiculite nanosheet dispersion is the same as in Example 1;

[0050] 2) Weigh 113 mL of the vermiculite nanosheet dispersion in 1) and add it to a suction filtration device, and perform suction filtration at a suction filtration pressure of 0.2 bar, so that the vermiculite nanosheets will slowly self-stack on the basement membrane to obtain a layered Vermiculite frame.

[0051] 3) Put the layered vermiculite framework obtained in 2) into a vacuum oven at 200°C for heat treatment for 12 h, and then soak in acetonitrile for 2 h for swelling treatment.

[0052] 4) Suction filter the swollen layered vermiculite framework obtained in step 3) in 53 mL of a 0.01% polyethylene oxide-bistrifluoromethanesulfonimide lithium acetonitrile mixed solution, and the suction pressure After that, it was taken out and placed in a glove box filled with argon to heat and dry to...

Embodiment 3

[0054] A layered composite solid electrolyte, the preparation method is as follows:

[0055] 1) The preparation of the vermiculite nanosheet dispersion is the same as in Example 1;

[0056] 2) Weigh 515 mL of the vermiculite nanosheet dispersion in 1) and add it to a suction filtration device, and perform suction filtration at a suction filtration pressure of 0.2 bar, so that the vermiculite nanosheets will slowly self-stack on the basement membrane to obtain a layered Vermiculite frame.

[0057] 3) Put the layered vermiculite framework obtained in 2) into a vacuum oven at 200°C for heat treatment for 12 h, and then soak in acetonitrile for 2 h for swelling treatment.

[0058] 4) Suction filter the swollen layered vermiculite framework obtained in step 3) in 240 mL of 0.01% polyethylene oxide-bistrifluoromethanesulfonimide lithium acetonitrile mixed solution, and the suction pressure After that, it was taken out and placed in a glove box filled with argon to heat and dry to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com