Pneumatic type thermal blockage dredging filter screen based on waste gas and dust purification

A dust purification and filter screen technology, applied in gas treatment, chemical instruments and methods, combined devices, etc., can solve problems such as obstruction of exhaust gas purification and blockage of filter screens, so as to improve heat production efficiency, improve pass resistance efficiency, and improve collection effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

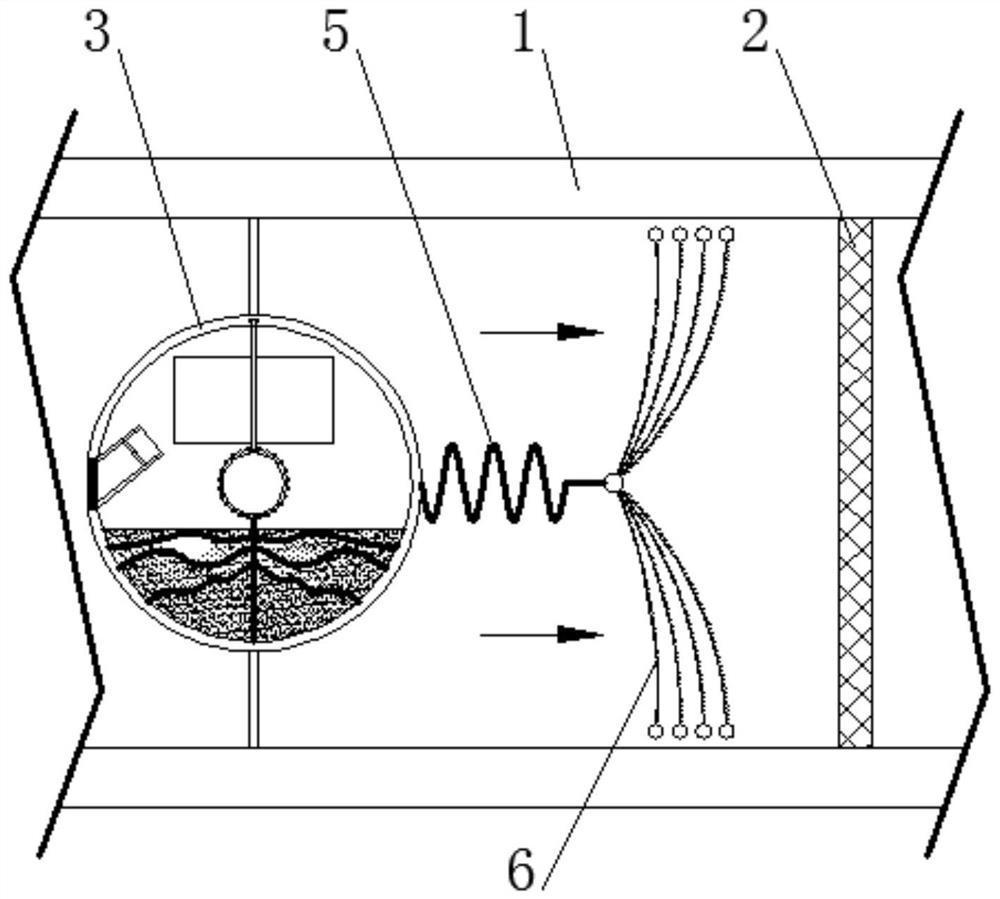

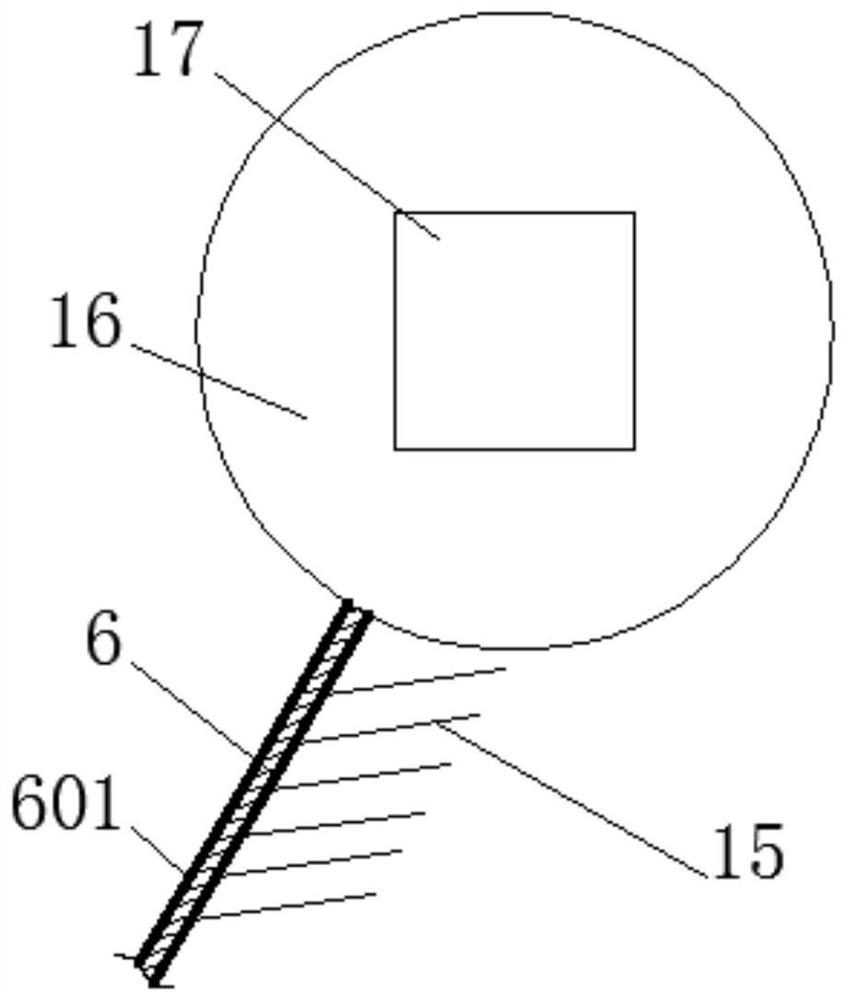

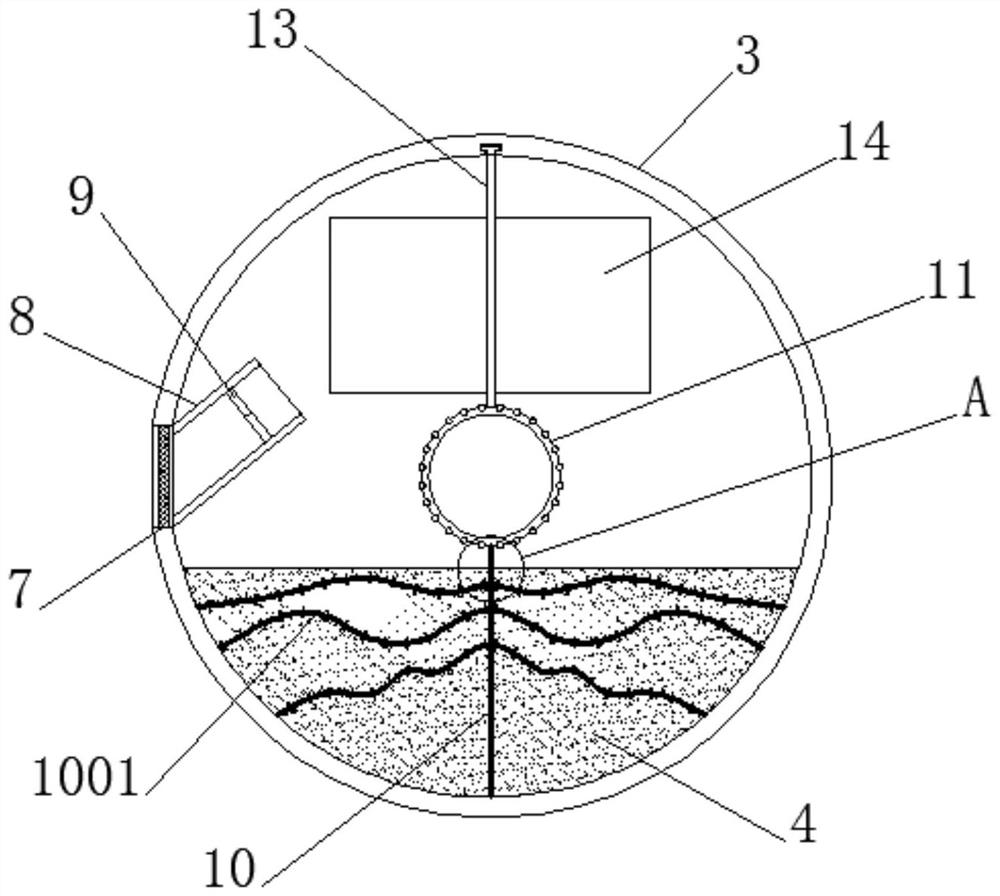

[0044] see Figure 1-3 , a pneumatic heat resistance filter screen based on exhaust gas dust purification, comprising an exhaust gas discharge pipe 1, the inner wall of the exhaust gas discharge pipe 1 is fixedly connected with a first filter screen 2 and an air flushing balloon 3 located on the left side of the first filter screen 2 The air flushing ball 3 is filled with reducing iron powder 4, the end of the air flushing ball 3 close to the first filter screen 2 is fixedly connected with a memory alloy spring 5, and the outer end of the memory alloy spring 5 is fixedly connected with a plurality of evenly distributed The metal through-resistance fiber rope 6, the left end of the air flushing balloon 3 is dug with a through hole 7, the inner wall of the air flushing balloon 3 is fixedly connected with the exhaust gas conduit 8 located outside the through hole 7, and the inner wall of the exhaust gas conduit 8 is fixedly connected with a pair of semicircles pressing against eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com