Laser processing apparatus, laser processing method, and correction data generation method

A laser processing and laser technology, applied in the direction of optical devices, measuring devices, laser welding equipment, etc., can solve problems such as difficult keyhole depth measurement, and achieve the effect of accurate depth measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0127] (Embodiment 1) Item 1

[0128]

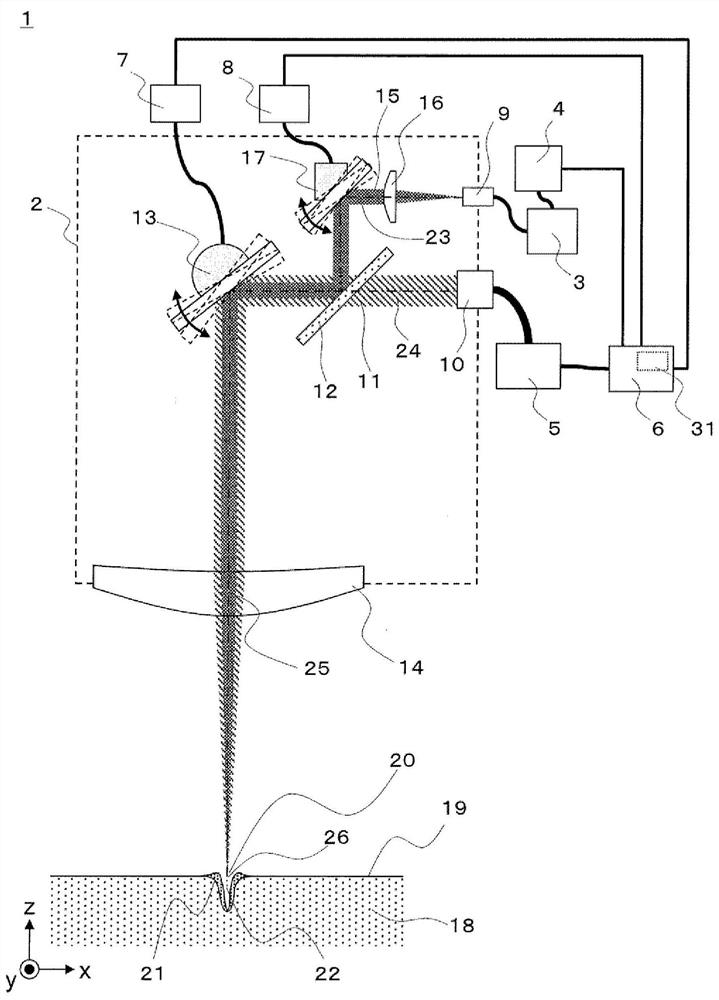

[0129] figure 1 It is a figure which shows the structure of the laser processing apparatus 1 in Embodiment 1 of this invention. The laser processing device 1 is composed of a processing head 2 , an optical interferometer 3 , a measurement processing unit 4 , a laser oscillator 5 , and a control unit 6 . Optical interferometer 3 emits measurement light 15 for OCT measurement, and laser oscillator 5 oscillates processing laser light 11 for laser processing. The measurement light 15 is input to the processing head 2 from the measurement light introduction port 9 , and the processing laser light 11 oscillated by the laser oscillator 5 is input to the processing head 2 from the processing light introduction port 10 .

[0130] The processing laser light 11 introduced from the processing light inlet 10 passes through the dichroic mirror 12 , is reflected by the first reflection mirror 13 , passes through the lens 14 , and is focused on the p...

Embodiment approach 2

[0247] Embodiments of the present disclosure will be described below with reference to the drawings. In addition, in each figure, the same code|symbol is attached|subjected to the common component, and their description is abbreviate|omitted suitably. Matters not described are the same as those in Embodiment 1.

[0248] [Structure of laser processing device]

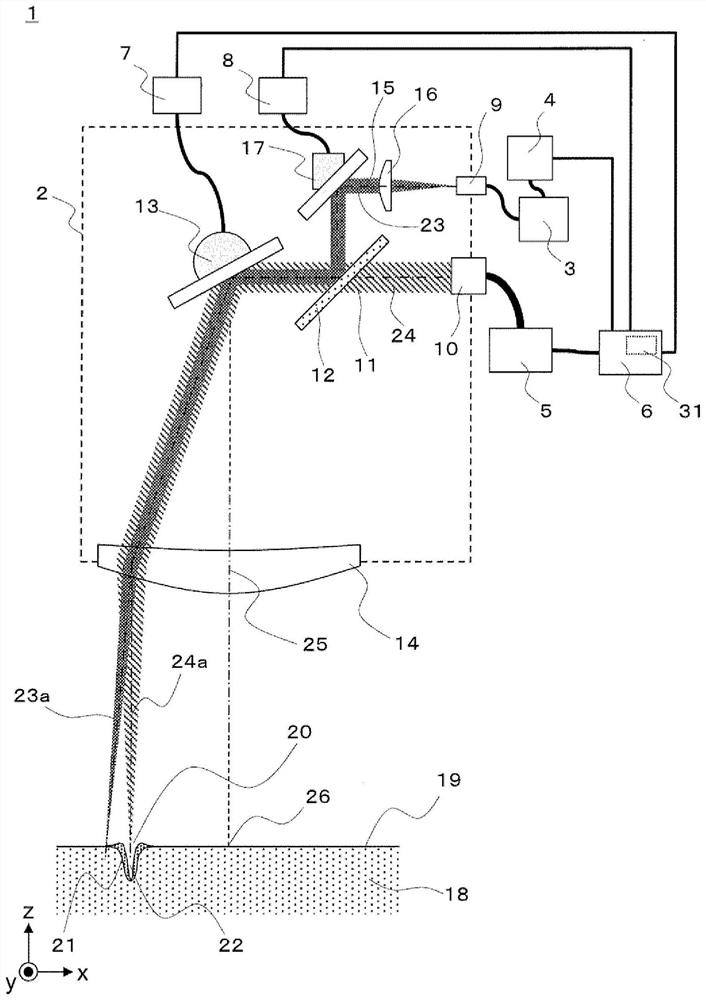

[0249] use Figure 16 The configuration of the laser processing apparatus 1 according to the embodiment of the present disclosure will be described. Figure 16 It is a figure which schematically shows the structure of the laser processing apparatus 1 of this embodiment.

[0250] The laser processing device 1 includes a processing head 2 , an optical interferometer 3 , a measurement processing unit 4 , a laser oscillator 5 , a control unit 6 , a first driver 7 , a second driver 8 , and a third driver 41 .

[0251] The optical interferometer 3 emits measurement light 15 for OCT measurement. The emitted measurement lig...

Deformed example 1

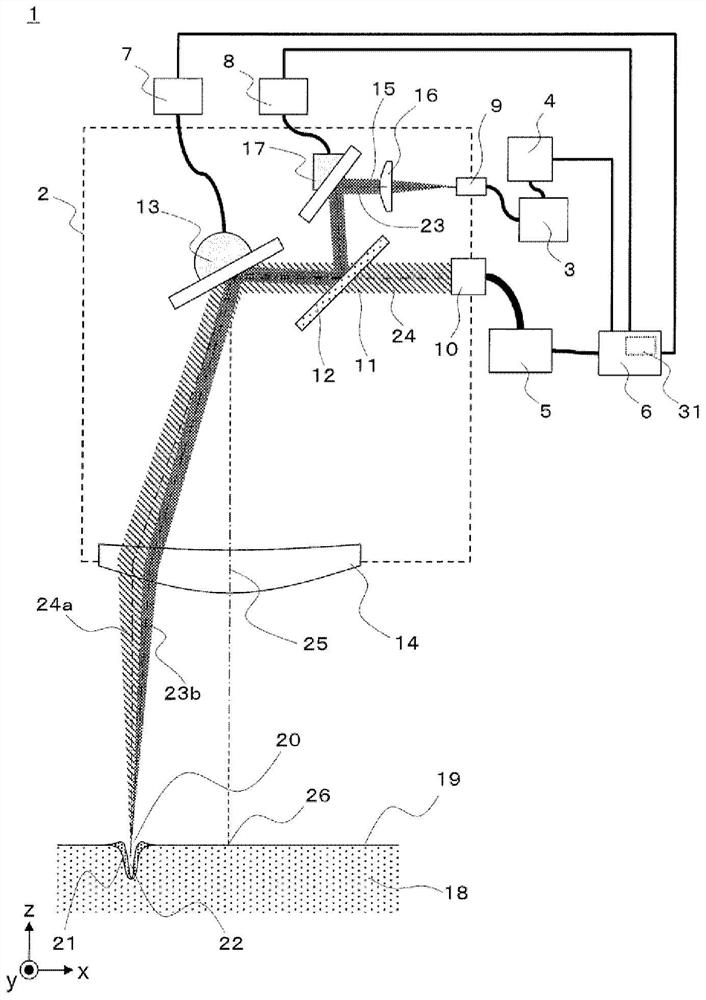

[0463] In the embodiment, in order to change the direction of the optical axis of the measurement light 15 , the case of using the second mirror 17 as a galvanometer mirror was described as an example, but the present disclosure is not limited thereto.

[0464] The second mirror used in the laser processing device 1 may be, for example, disposed between the measurement light inlet 9 and the dichroic mirror 12 and capable of changing the direction of the optical axis of the measurement light 15 under the control of the control unit 6 .

[0465] The second reflection mirror 35 of this structure is shown in Figure 36 . Figure 36 It schematically shows the laser processing device 1 using the second mirror 35 .

[0466] Figure 36 The laser processing device shown in 1 replaces the Figure 16 The second reflection mirror 17 shown by etc. has a second reflection mirror 35 , and further has a moving table 36 and a table driver 37 . in addition, Figure 36 The laser processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com