U + Z type seed precipitation tank and working method thereof

A working method and trough-dividing technology, which is applied in the preparation of alkali metal aluminate/aluminum oxide/aluminum hydroxide, etc., can solve the problems of large land occupation, long chute, unfavorable investment, etc., so as to save land occupation and reduce the average height , the effect of reducing the length of the pipe network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the accompanying drawings.

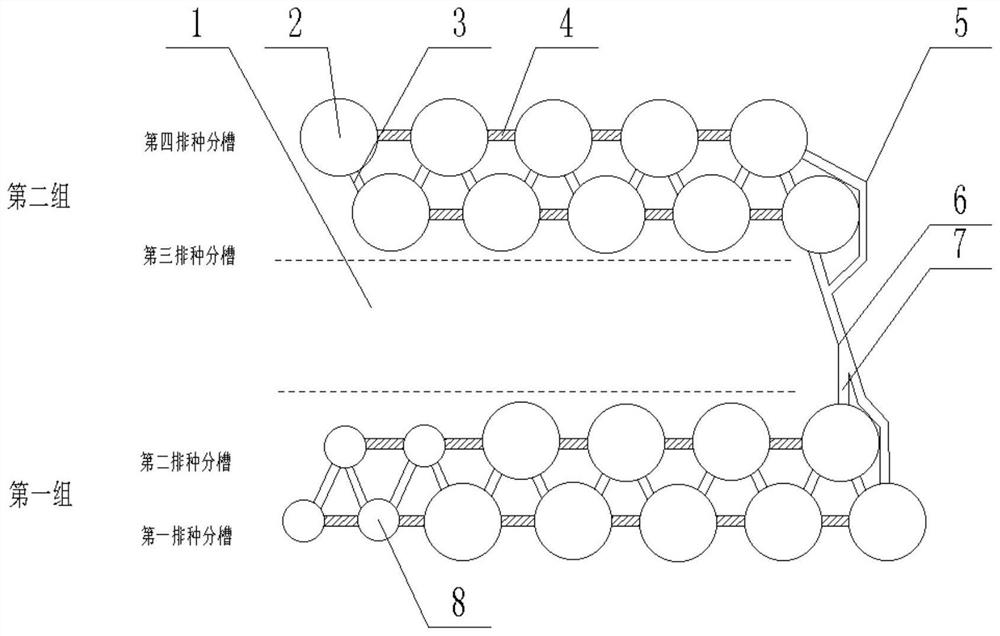

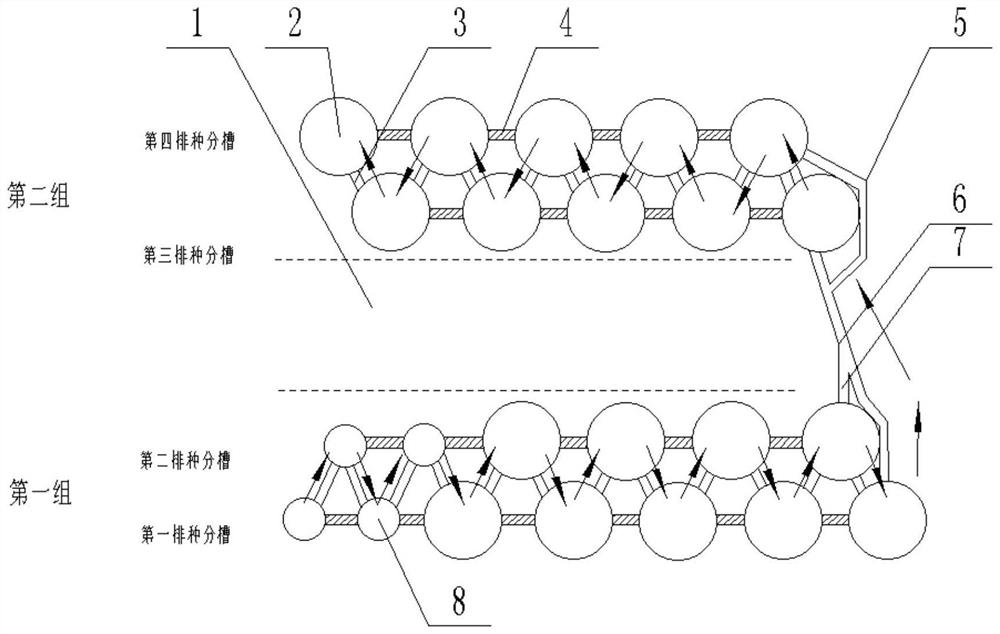

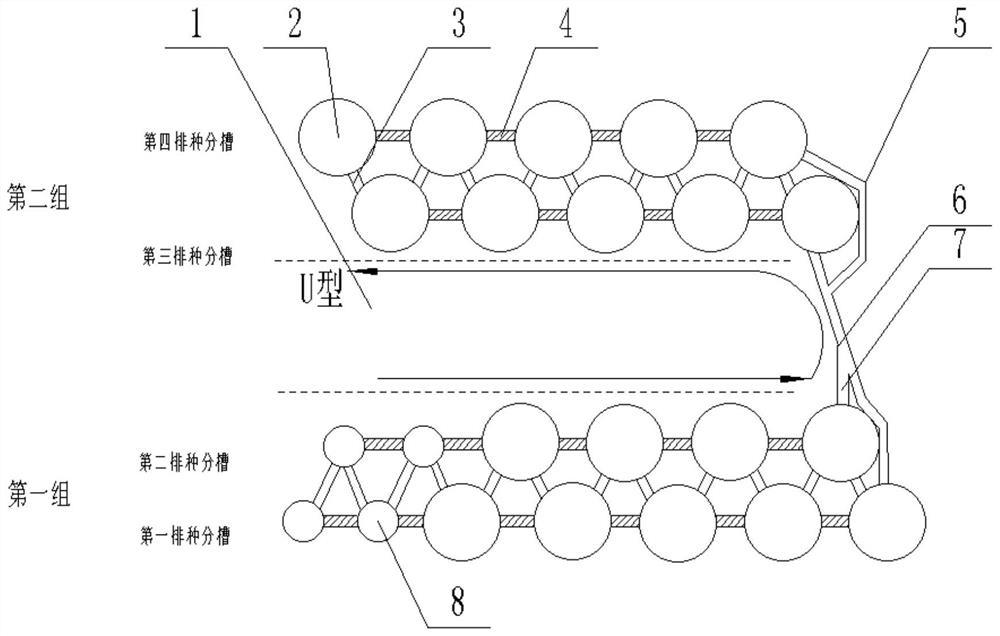

[0028] figure 1 It is a schematic diagram of the top view structure of the U+Z type seed sub-groove of the present invention, figure 2 It is a schematic diagram of the normal working slurry flow direction of the U+Z type seed tank of the present invention, image 3 It is a schematic diagram of the U-shaped flow direction of the slurry between the U+Z type seed tank groups of the present invention, Figure 4 It is a schematic diagram of the Z-shaped flow direction of the slurry in the U+Z type seed tank group of the present invention, Figure 5 It is a schematic diagram of the flow direction change of the U+Z type seed sub-groove and local compartment overhaul slurry flow direction of the present invention, as shown in the figure:

[0029] The U+Z type seed sub-grooves o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com