Purification method of Lyocell spinning coagulating bath recovery liquid

A technology of recovery liquid and coagulation bath, which is applied in the field of purification of Lyocell spinning coagulation bath recovery liquid, can solve problems such as rising cost of NMMO solution recovery, reduced service life of ion resin, and increased acid-base usage of regeneration liquid, etc., to achieve good decolorization effect, the effect of lowering the conductivity and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment adopts the following method to purify the liquid to be recovered from the coagulation bath:

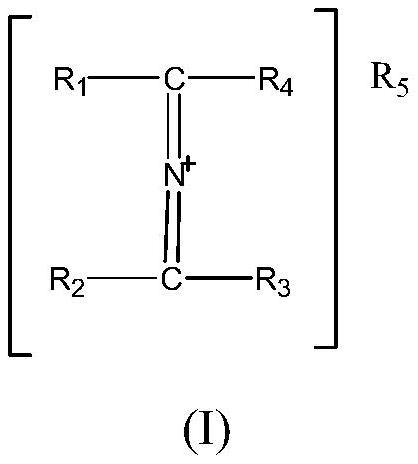

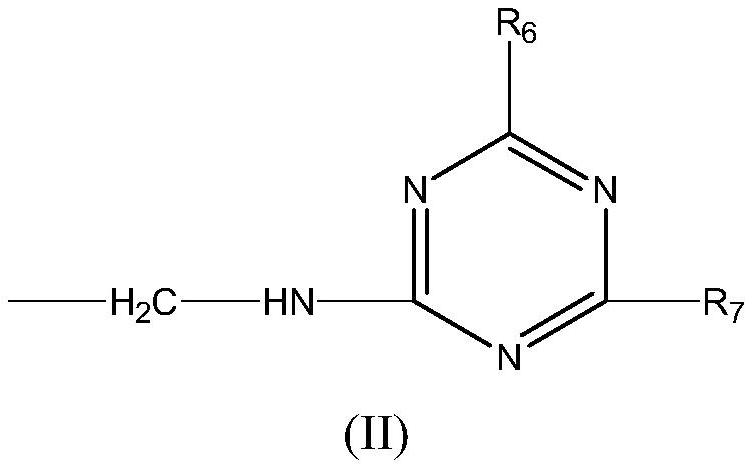

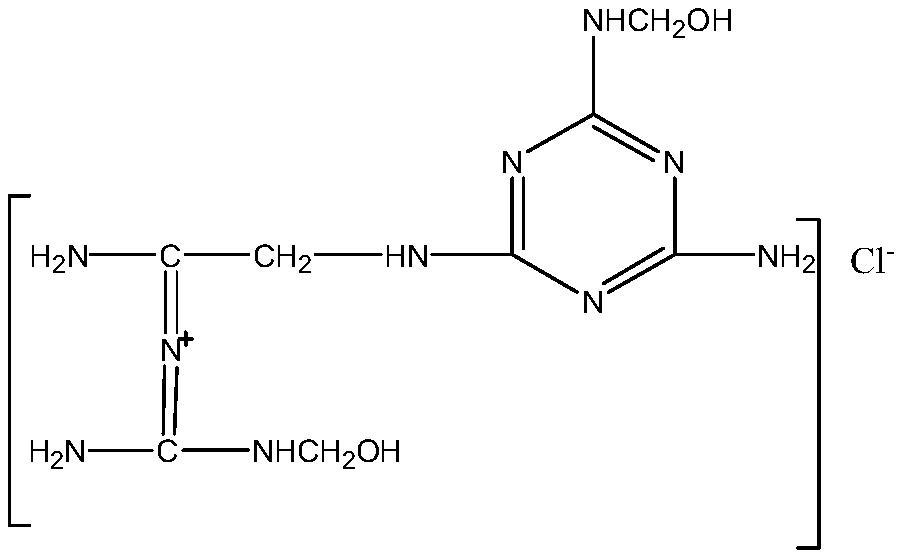

[0044] Add 100ppm decolorizing agent dicyandiamide formaldehyde polymer-polymerized aluminum sulfate (the decolorizing agent shown in corresponding formula (IV) and the inorganic-organic compound that is compounded with aluminum salt in the NMMO coagulation bath to be recovered liquid that mass fraction is 18% Polymer decolorizer), fully stirred for 10min, then added flocculant polyacrylamide 10ppm, removed scum by air flotation to obtain a clear liquid, and then passed the clear liquid into an anion and cation exchange resin for recovery.

Embodiment 2

[0046] The present embodiment adopts the following method to purify the liquid to be recovered from the coagulation bath:

[0047] Add 120ppm decolorizer dicyandiamide formaldehyde resin (decolorizer shown in corresponding formula (IV)) in the coagulation bath to be recovered liquid that mass fraction is 20% NMMO, fully stir 12min, then add flocculant polyferrous sulfate 50ppm and Polyacrylamide 15ppm, remove scum by air flotation to obtain a clear liquid, and then pass the clear liquid into an anion and cation exchange resin for recovery.

Embodiment 3

[0049] The present embodiment adopts the following method to purify the liquid to be recovered from the coagulation bath:

[0050] Add 150ppm decolorizing agent melamine-dicyandiamide-formaldehyde resin (corresponding decolorizing agent shown in formula (III)) to the liquid to be recovered in the coagulation bath of 25% NMMO by mass fraction, fully stir for 15min, then add flocculant polymerization chlorination Iron 60ppm and polyacrylamide 20ppm, scum is removed by air flotation to obtain a clear liquid, and then the clear liquid is passed into an anion and cation exchange resin for recovery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com